Ocr25Al5 Wire Widely used in industrial furnace, household appliances, metallurgy, machinery, aircraft, automobile, military and other industries to produce heating elements and resistance components. Ocr25Al5 Wire

With our rich experience and perfect after-sales service, we have won the praise of our customers and occupy a position in the domestic and foreign market of 55 gallon drum insulation blanket, pt100 resistance, mineral insulated thermocouple. In the future, we will strive towards new goals and take a firm step towards a new journey with our partners. We have sophisticated equipment, state-of-the-art technologies and perfect quality test methods, and a variety of product quality indicators have achieved the standard.

0Cr25Al5 resistance electric heating wire

Fekelar alloy has the characteristics of high resistivity, low resistivity, high working temperature, high temperature oxidation resistance and corrosion resistance.

Widely used in industrial furnace, household appliances, metallurgy, machinery, aircraft, automobile, military and other industries to produce heating elements and resistance components.

Resistance wire 0Cr25Al5 / OCr25Al5 ferrochrome alloy

Resistance heating wire is a common material of ferrochrome aluminum alloy.

Fekelar alloy has the characteristics of high resistivity, low resistivity, high working temperature, high temperature oxidation resistance and corrosion resistance.

Widely used in industrial furnace, household appliances, industrial furnace, metallurgy, machinery, aircraft, automobile, military industry and other industries to produce heating elements and resistance components.

Size range:

Ocr25Al5 Wire

Thread: 0.01 -10 mm

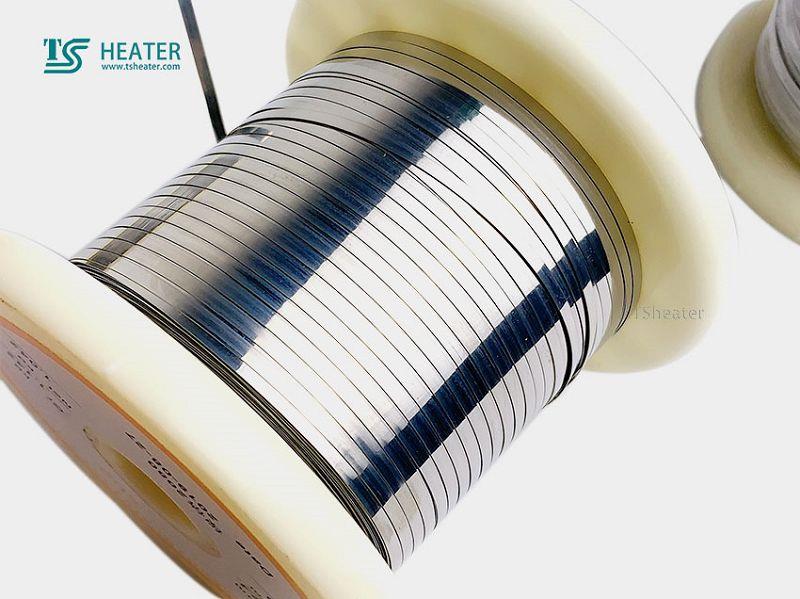

Ribbon: 0.05 * 0.2-2.0 * 6.0 mm

Band: 0.05 * 5.0 -- 5.0 * 250 mm

Bar: 10 to 50 mm

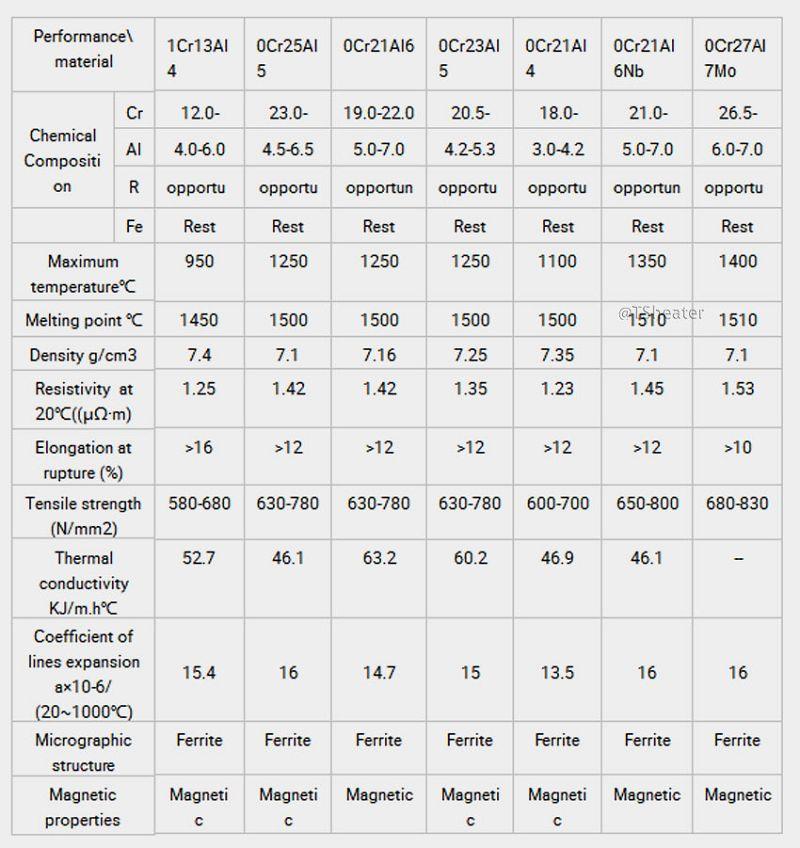

FeCrAl alloy series: OCr15Al5, 1Cr13Al4, 0Cr21Al4, 0Cr21Al6, 0Cr23Al5, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2, etc.

Details

Ocr25Al5 Wire

Place of Origin:GuangZhou, China

Brand Name:TS W

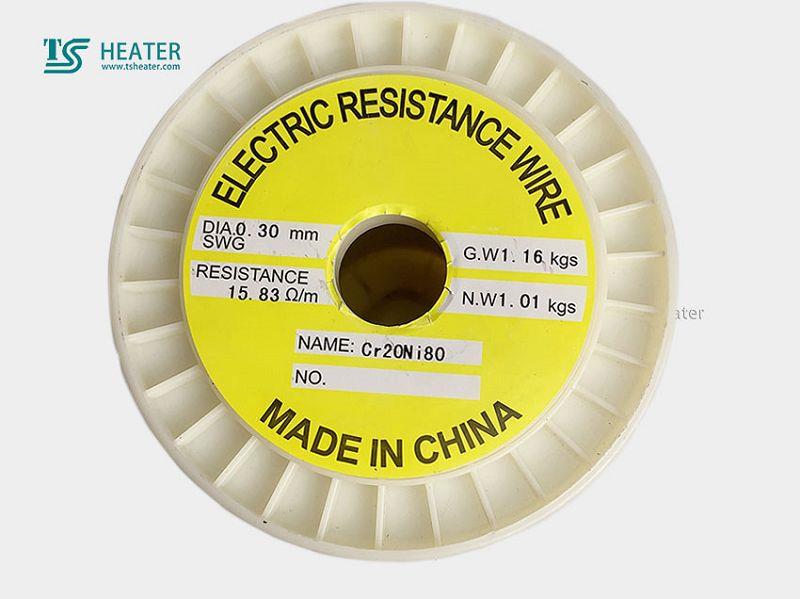

Model Number:0Cr25Al5

Type:Bare

Application:Heating

Conductor Material:Copper Clad Aluminum

Conductor Type:Solid

Surface:Bright

Resistivity:1.42

Maximum Temperature:1250℃

Melting Point:1500℃

Technique:Cold Drawing

Treatment:Hydrogen Annealing

Condition:Soft Annealed

Certificate:ISO9001, SGS

Delivery Time:7-20 Days

Tensile Strength:630-780

Ocr25Al5 Wire

Delivery & Enquiries:

Most items are available for delivery in 3 to 7 working days. However, Ts heater do offer additional emergency services for customers who are in a breakdown situation. This includes a 48hr services on Mica products, Cartridge Heaters and Ceramic Knuckle Heaters. For all enquires please contact a member of our sales team who will be happy to assist.

We always adhere to the "quality, reputation" as the purpose of service, and our 1.6mm Tafa Alcro/ Ocr25al5 Thermal Spray Wire for Boiler Tubes& Tube Shilds have been gradually developed overseas markets. We have a deep understanding of the meaning of 'customer-oriented', and will 'service' throughout every detail of the company's operation and management, so as to win extensive trust and support from customers. We always take every job seriously, pursuing everything to satisfy customers, and never sensationalize or deceive.