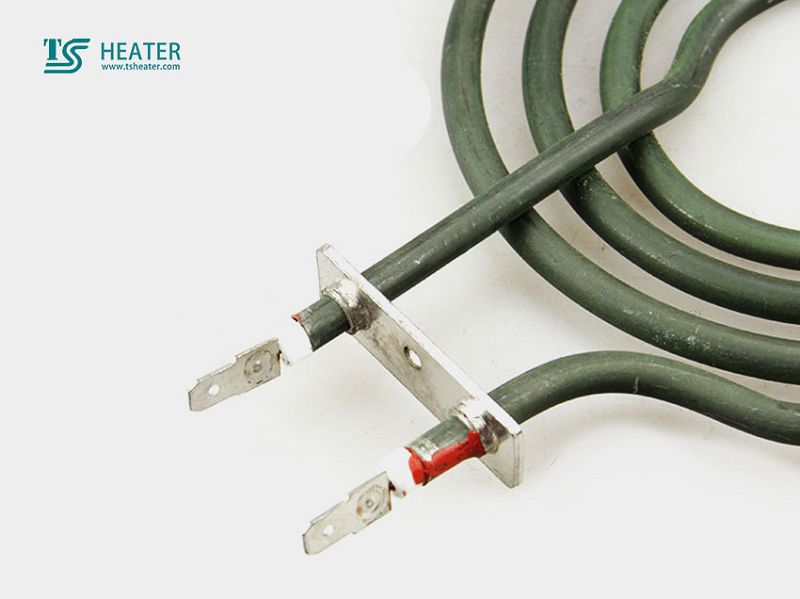

Grill heating elements has simple structure, high thermal efficiency, good mechanical strength and good adaptability to harsh environment.It can be used for heating all kinds of liquids and acid, base and salt as well as for melting metals (lead, zinc, tin,) with low melting point.Grill Heating Elements

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for spark plug thermocouple, coil heater for bolts, magnesium tube. We have rich manufacturing experience and perfect testing methods. After long-term unremitting efforts, our company has established a good reputation, stood out among the peers, and won the trust and support of our customers. We value employee development and provide learning opportunities so that everyone can develop in an all-round way in the process of hard work and learning. It is the company's long-term development policy to pay attention to product quality and technology investment. We have won the unanimous trust and praise of customers at home and abroad with the business tenet of customer first, good product quality, perfect service system, and punctual delivery time.

Grill heating elements has simple structure, high thermal efficiency, good mechanical strength and good adaptability to harsh environment.It can be used for heating all kinds of liquids and acid, base and salt as well as for melting metals (lead, zinc, tin,) with low melting point.

Electrical strength test:

A. Electrical strength in cold state: it shall be able to withstand 50Hz,1min withstand voltage, cut off current 5mA, without breakdown and flashover.

Rated voltage test voltage 250V 1250V

B. Electrical strength at operating temperature: 50Hz,1min withstand voltage, cut off current 5mA, no breakdown, flashover.

Rated voltage test voltage 250V 1000V

3. Leakage current at operating temperature

Under the condition of full heat release, the leakage current of the electric heat pipe is 0.5m A, with the input of 1.15 times rated power.

4. Overload test

Under the condition of sufficient heat release, the electric heat pipe is powered on with 1HRS of rated power 1.27 times, and cooled with 0.5HRS to room temperature (forced cooling is allowed) after power failure, so that the cycle is repeated for 30 times without damage.

5. Enclosure sealing test of electric heat pipe (pipe crack test)

The electric heat pipe shall be immersed in 3HRS of acidified water (2%-3% hydrochloric acid, sulfuric acid or nitric acid). The two end faces of the electric heat pipe shall be exposed to at least 5mm of liquid level. After testing, the performance requirements of item 2~3 shall be satisfied.

6. Sealing test

The electric heat pipe shall be placed at 24HRS in an environment with a temperature of 60℃ and a humidity of 95%, and shall meet the second to third performance requirements after being placed.

7. Life test

Under the condition of sufficient heat release, the electric heat pipe is powered on by 1HRS at rated voltage, and cooled by 0.5HRs to room temperature (forced cooling is allowed) after power off. The accumulative working time is up to 3000HRs.

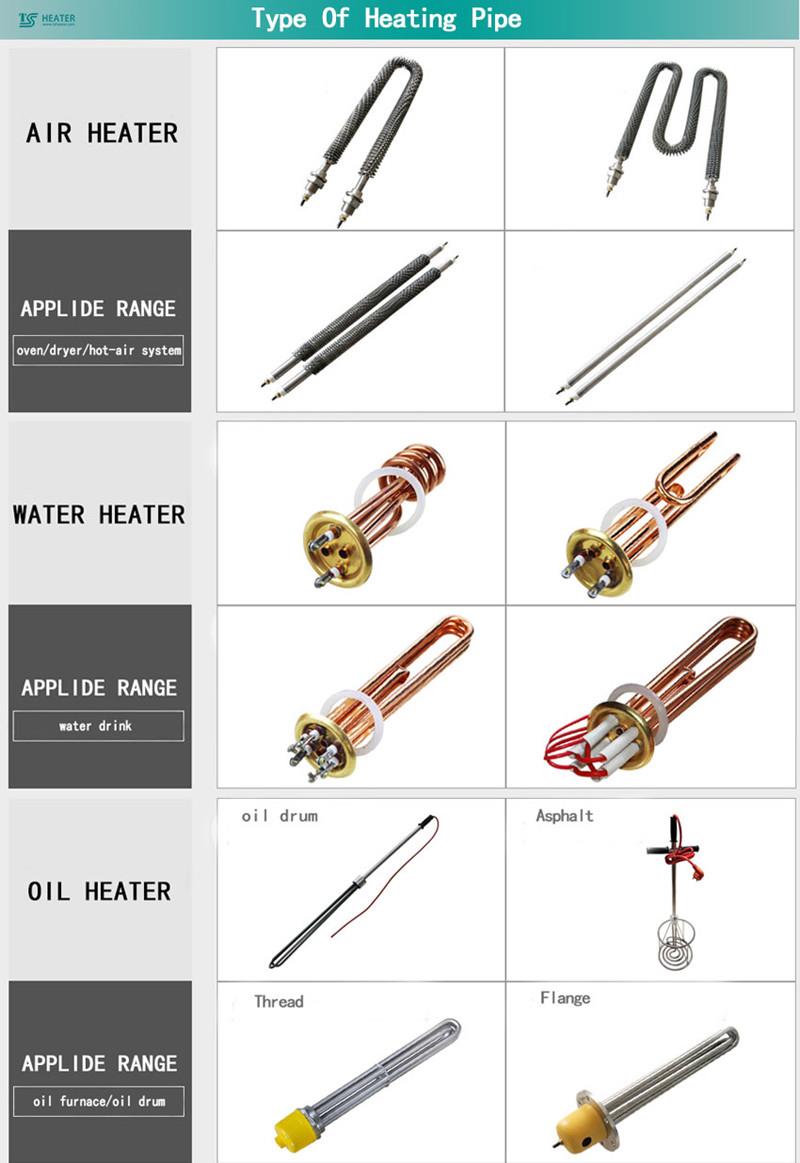

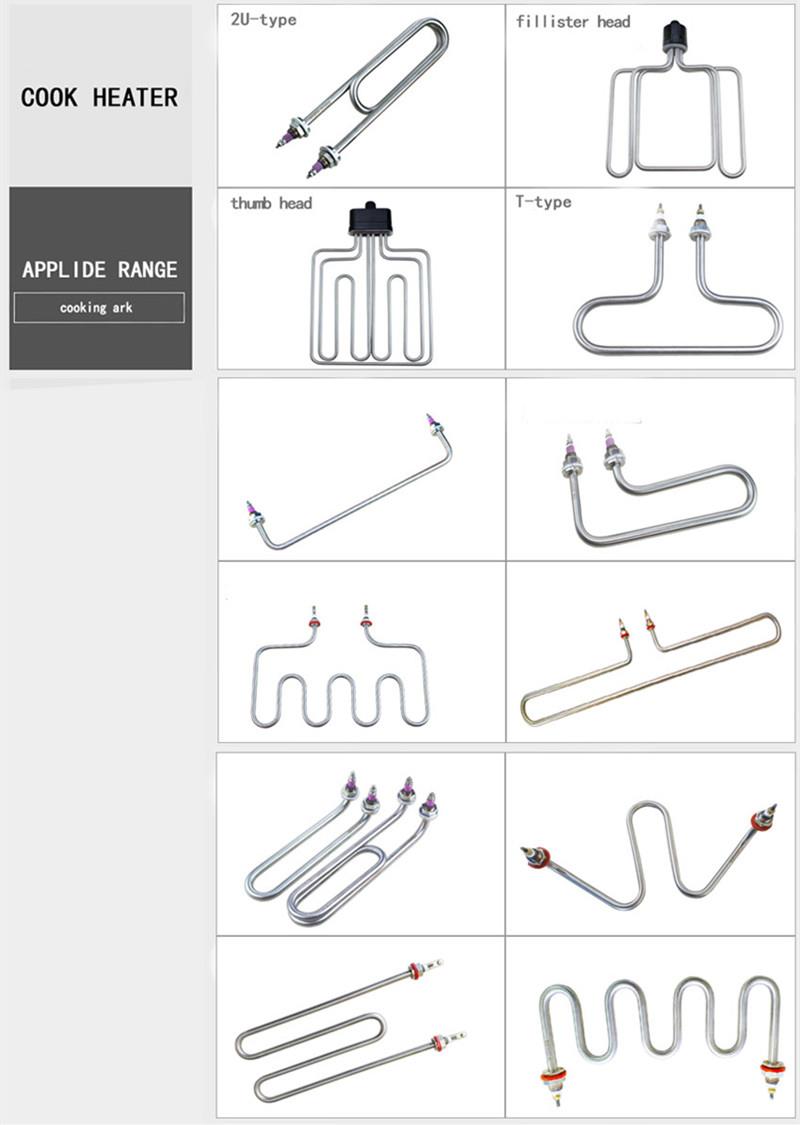

Type of industrial tubular heaters:

TS heater Founded in 2009, belong to factory investment company, with strong technical & products knowledge support. TS focused on electric & industry heaters’ technology research, development,co-production and sales. Mainly engaged in electric heating tube,shaped tubular heater ,cartridge heater, Teflon heater, Hot runner heater, cast in aluminum/iron/brass heater,,Thermocouple, TC ,RTD pt100, Nickel Chrome Cr20Ni80, Heating cable, Blanket Drum heater, Silicone heater, Mica band heater, Ceramic heater, ........

All the products are widely used in electroplating, chemical, plastics, machinery

Our 110V 220V 230V 240V 380V 480V Electric Water Flange Tubular Immersion Heater 2kw has been sold nationwide and exported to the world, enjoying a high reputation in the industry for its superior performance. With many years of professional team and brand building, we have advanced special production equipment and production capacity, and our craftsmanship and technical level have ranked among the forefront of the domestic industry. We regard the construction of corporate culture as an important task of the company, closely integrating the actual work, and organizing the implementation in a comprehensive and systematic manner.