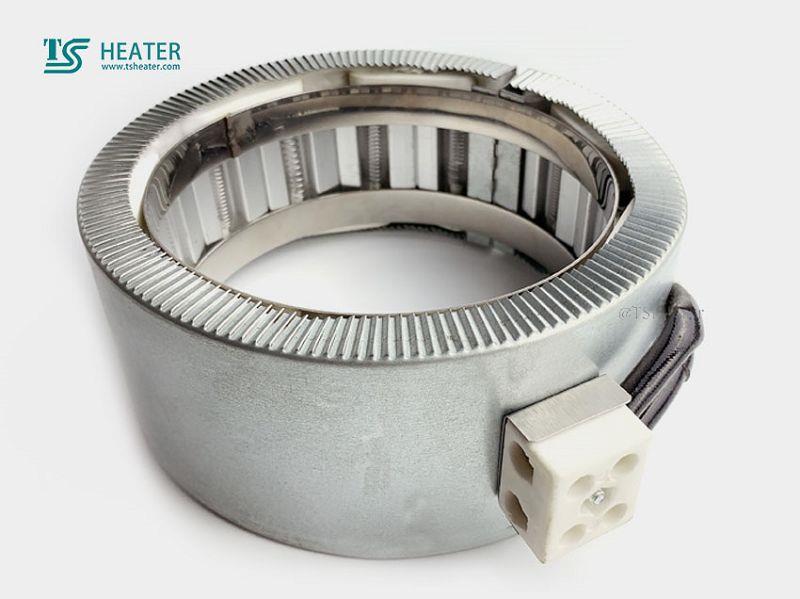

IR energy saving band heater is professional energy-saving device , aim to assist plastic machine increasing the heat efficiency. Utilizing the high resistance heating wire to generate heat and through the infrared radiation way to conduct thermal effect for plastic processing machine.IR Energy Saving Band Heater

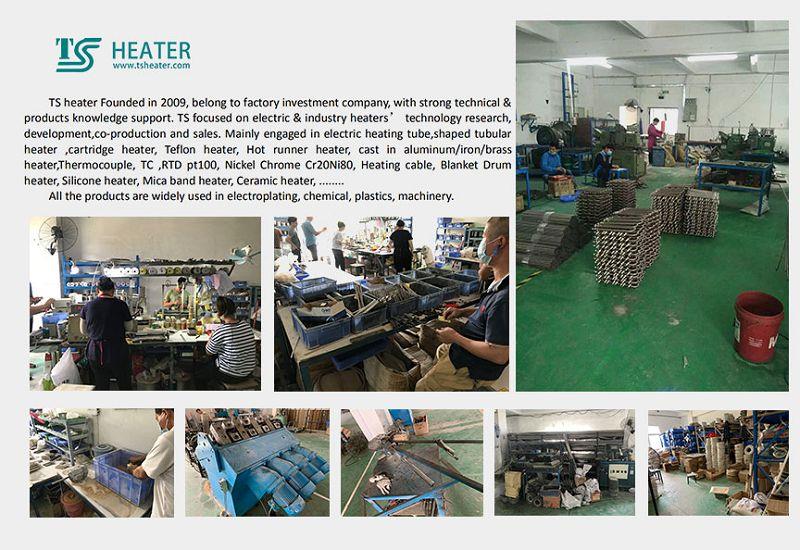

Our company will keep the aim of seeking progress with science and technology and develop better and better powerblanket drum heater, coil winder, hot water heater element to meet the needs of customers. We believe this sets us apart from the competition and makes customers choose and trust us. Over the years, our company has always insisted on taking technological innovation as the basis and management innovation as the guarantee to create a unique business model. We have achieved a win-win situation with our customers by virtue of advanced process equipment, technical advantages, and a high-quality talent team.

IR Energy Saving Band Heater IR energy saving band heater is professional energy-saving device , aim to assist plastic machine increasing the heat efficiency. Utilizing the high resistance heating wire to generate heat and through the infrared radiation way to conduct thermal effect for plastic processing machine.

It adopts import electric wire as heating conduction, at maximum extent increase the heat transfer efficiency between heating element and barrel. Electric heat transfer efficiency rate up to 99.8%. The inner use the aerospace grade material air-gel as the insulation material. The surface temperature is under 35℃, which improve the shortcomings for traditional band heater, such as low conversion efficiency of electric heat, low heat transfer efficiency, high temperature in surface etc, thereby the Nano infrared band heater could achieve to saving energy.

Plastic machine nano infrared heater generates high heat by high-resistance wires which is reflected by quartz halogen heating tubes. It has high thermal efficiency, excellent energy-saving effect and quite low heater surface temperature. Following induction heating, it is another high energy-saving heating technology which is now widely used in plastic machines.IR Energy Saving Band Heater

Application range: IR Energy Saving Band Heater

injection molding machine, granulator, extruder, drawing machine, blown film machine and other plastic machinery and other system need to use electric heat.

Features: IR Energy Saving Band Heater

1. 4ultras:ultra-high energy-saving,ultra-low surface temperature,ultra-fast heating rate,ultra long service life

2. Electric heat transfer efficiency up to 99.8%,energy saving rate up to 30% -83%

3. Infrared radiation heating mode, high efficiency, unidirectional radiation

4. The surface temperature is under 35 degrees, greatly improve the operating environment

5. Easy to install and replace,simple and stable structure, the service life of up to 50,000 hours;

Details:

Order guide:

When order IR energy saving band heater ,please kindly inform us the information as following:

1.The inner diameter (mm) (or outer diameter when the heater is used inside) and length (mm) of heaters

2.Width of heaters

3.Voltage and power density

4.Position and size of the hole for thermocouple

5.Wiring type and position

6.Content of the stamping if needed

7.Special gap if Necessary

8.Order quantity

9.Delivery date

'Good quality comes 1st; assistance is foremost; business enterprise is cooperation' is our business enterprise philosophy which is regularly observed and pursued by our company for 122*122mm Infrared Ceramic Panel Heater Element for Conveying. We win together with our partners, grow together with our customers, share the fruits of development with our shareholders and employees, and develop with the open and shared era. In the process of continuous development and improvement, our company attaches great importance to the interests of customers and our commitment to customers.