Submersible Oil Heater,The surface power of the heating tube is 5.6w/cm2, which is suitable for liquid heating with good fluidity, less solid deposition and no crystallization of the liquid on the surface of the electric heater after cooling.

Our company aim to provide world wide brand of made-in-China solid state relay arduino, compressed air heaters tubular, heat resistant mat kitchen. We have strong technical research and development force, and our research level has been in line with international standards. We think this sets us apart from the competition and makes prospects choose and trust us.

1. Titanium, zirconium, SUS304, SUS316 stainless steel tubes are used.

2. Design the surface power of the heating tube and determine the pipe diameter according to the installation location, chemical liquid properties and solid substance deposition characteristics in the liquid. Common specifications for pipe diameter are Ø 11 mm, 17 mm, 25 mm, Ø Ø Ø 30 mm, Ø 32 mm and 45 mm, Ø Ø 50 mm.

3. Submersible Oil Heater, liquid heating, heating tube surface power 5.6 W/cm2, suitable for liquid and solid deposit less, not in the heater surface cooled liquid crystalline liquid heating.

4. 45 mm diameter Ø series of products with low power design surface, good durability, especially for horizontal heating circuit board.

5. The voltage is 120V single-phase, 220V, 380V, 220V three-phase, 380V three-phase, power from 0.5kW to 140KW.

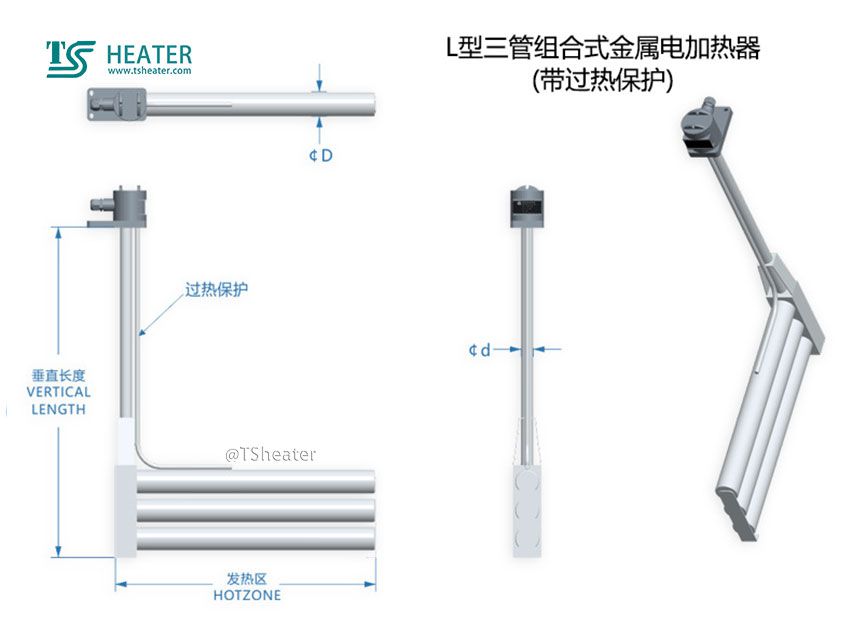

6. All heaters can be equipped with overtemperature protection switch or temperature sensing probe.

7. All heaters adopt international inspection standards to ensure safe electrical performance

Applicable environment: all kinds of electroplating corrosion liquid, due to the difference in steel selection.

Specification design: you can refer to the list of common specifications, or according to customer requirements to design various shapes, specifications, processes, etc.

For details, please consult our engineers and technicians

Persisting in 'High top quality, Prompt Delivery, Aggressive Price', now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients' large comments for 1300c Vacuum Brazing Furnace for Vacuum Distillation Process of Volatile Elements (such as lead, zinc, etc.) in Alloy Materials. In line with the purpose of scientific and technological innovation, focusing on products, applying to life and serving the society wholeheartedly, the company integrates research and development, production and sales with our leading technical level in the industry. We meet up to personal requirements with all products of your very own styles.