Infrared Ceramic Resistance Compared with traditional steam, hot air and resistance heating methods, far-infrared heating has many advantages, such as fast heating speed, good quality of new products, small area of equipment, low production cost and high heating efficiency.Infrared Ceramic Resistance

We are committed to serving every customer with professionalism, providing customers with continuous and solutions for polyimide heating element, 55 gallon plastic drum heater, cnc centerless grinder and bringing endless wealth to customers. We always adhere to the customer first, attentively serves the demand group to move the user. We are proud to supply our products to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Infrared Ceramic Resistance Compared with traditional steam, hot air and resistance heating methods, far-infrared heating has many advantages, such as fast heating speed, good quality of new products, small area of equipment, low production cost and high heating efficiency.Use it instead of electric heating, its power saving effect is particularly significant, generally can save about 30% of the power, some occasions even up to 60% ~ 70%.

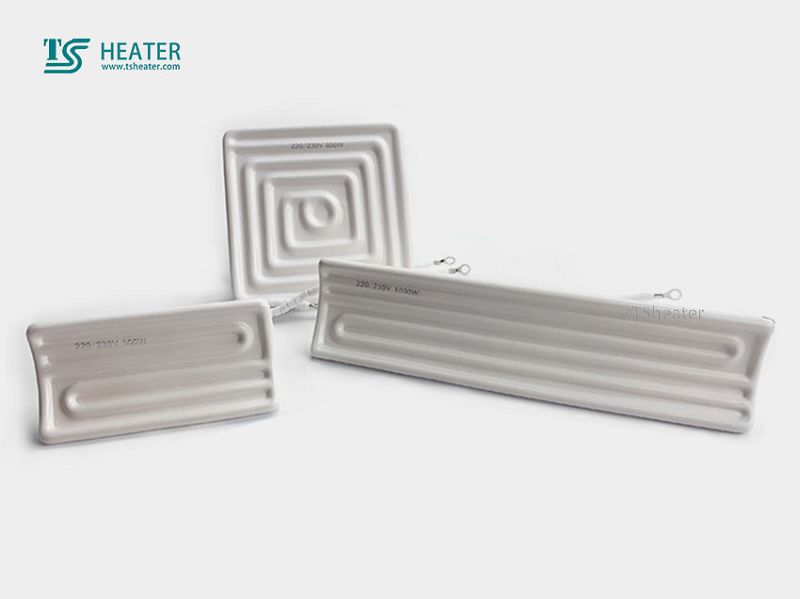

Their composition is as follows: Infrared Ceramic Resistance

1. Matrix: composed of ceramic materials with good thermal shock properties.

2. Heat: it is made of high-quality nickel-chromium alloy wire.

3. Glaze layer: group of metal oxide raw materials with good radiation performance from far away.

4. Add the right amount of additives to improve the radiation intensity and enhance the adaptability of the blank glaze.nguyen

5. Heat the substrate to 800℃ and place cold water for dozens of times without cracking.

Application: Infrared Ceramic Resistance

Buried ceramic far red radiation element is based on the guidance of advanced technology, coupled with years of research, the results.With high technology content, good overall performance, cleaning and sanitation, easy assembly, acid resistance, corrosion resistance, use, long life characteristics.Widely used in vacuum blister, food baking, medical and health and other infrared drying baking, curing and other occasions, in the electronic textile, light industry, mechanical and electrical chemical, medical, food and other industries has the ideal energy saving effect, has obvious social and economic benefits.

Can be customized according to customer's special requirements.Infrared Ceramic Resistance

Stock product:

We use advanced design and manufacturing testing equipment as a means to achieve high standards and high reliability for 18mm Ceramic Blackbody Infrared Heating Element. If you need any of our products, or have other items to be produced, please send us your inquiries, samples or detailed drawings. Should you be interested in almost any goods, remember to truly feel totally free to get in touch with us for further facts or be sure to deliver us email right, we will reply you in just 24 hrs as well as the finest quotation are going to be provided.