Ocr25Al5 Wire Widely used in industrial furnace, household appliances, metallurgy, machinery, aircraft, automobile, military and other industries to produce heating elements and resistance components. Ocr25Al5 Wire

'Excellent first' in mind, we operate closely with our customers and supply them with efficient and expert services for infrared heater element replacemen, flashforge creator pro heater cartridge, heat strip bunnings. The pursuit of success and the enjoyment process are the concrete manifestation of our outlook on life and career, and the high degree of condensing of our lofty ambition. We always insist on taking technological innovation as the driving force to enhance the core advantages of our company.

0Cr25Al5 resistance electric heating wire

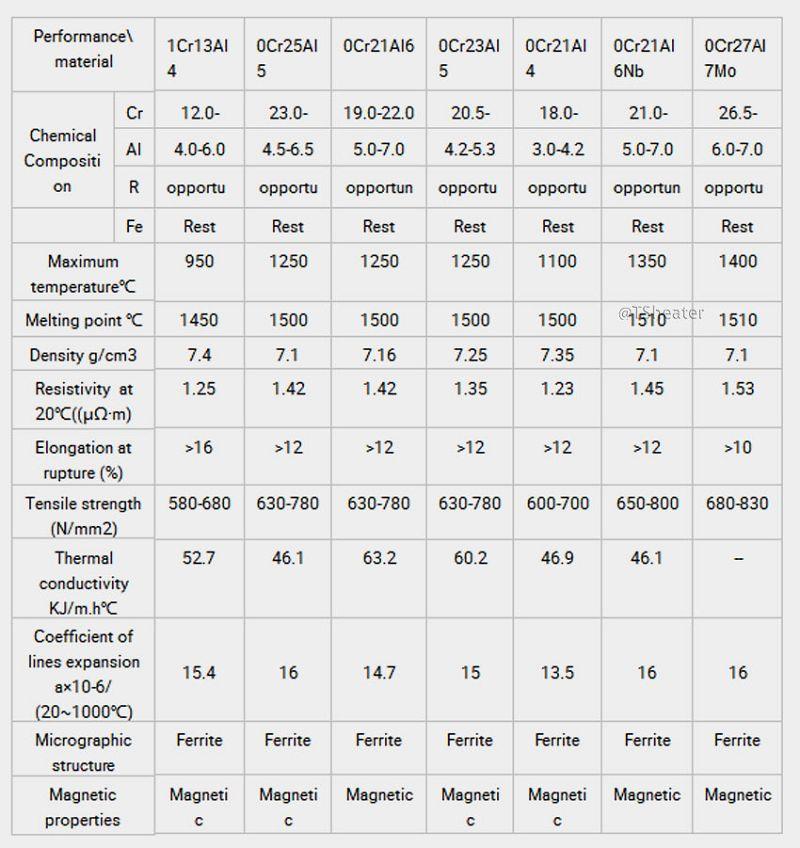

Fekelar alloy has the characteristics of high resistivity, low resistivity, high working temperature, high temperature oxidation resistance and corrosion resistance.

Widely used in industrial furnace, household appliances, metallurgy, machinery, aircraft, automobile, military and other industries to produce heating elements and resistance components.

Resistance wire 0Cr25Al5 / OCr25Al5 ferrochrome alloy

Resistance heating wire is a common material of ferrochrome aluminum alloy.

Fekelar alloy has the characteristics of high resistivity, low resistivity, high working temperature, high temperature oxidation resistance and corrosion resistance.

Widely used in industrial furnace, household appliances, industrial furnace, metallurgy, machinery, aircraft, automobile, military industry and other industries to produce heating elements and resistance components.

Size range:

Ocr25Al5 Wire

Thread: 0.01 -10 mm

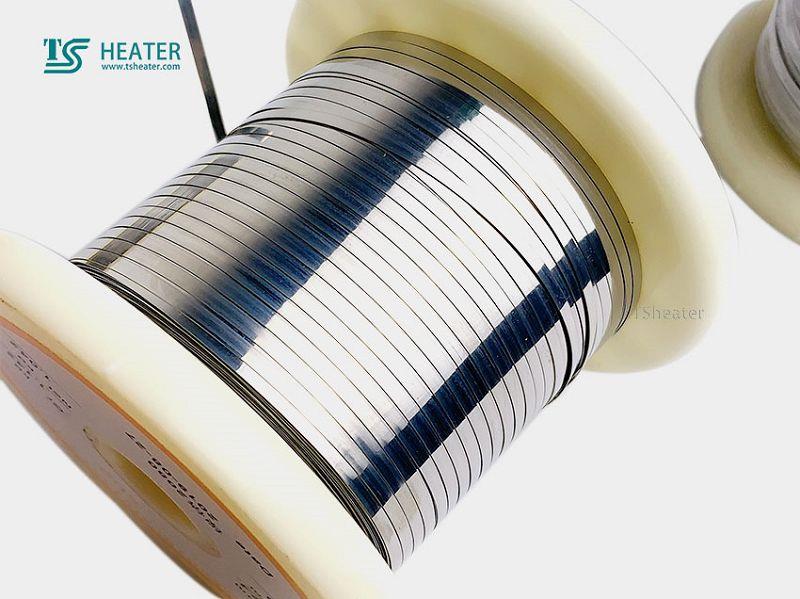

Ribbon: 0.05 * 0.2-2.0 * 6.0 mm

Band: 0.05 * 5.0 -- 5.0 * 250 mm

Bar: 10 to 50 mm

FeCrAl alloy series: OCr15Al5, 1Cr13Al4, 0Cr21Al4, 0Cr21Al6, 0Cr23Al5, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2, etc.

Details

Ocr25Al5 Wire

Place of Origin:GuangZhou, China

Brand Name:TS W

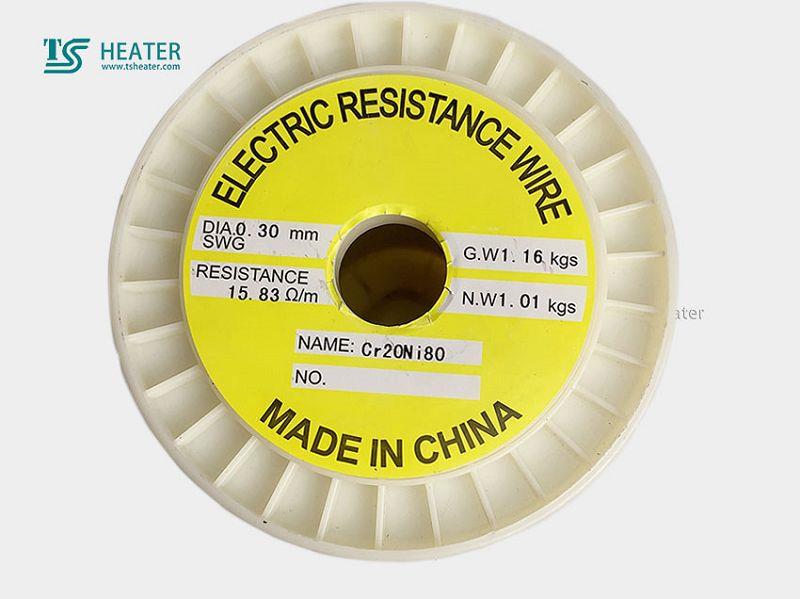

Model Number:0Cr25Al5

Type:Bare

Application:Heating

Conductor Material:Copper Clad Aluminum

Conductor Type:Solid

Surface:Bright

Resistivity:1.42

Maximum Temperature:1250℃

Melting Point:1500℃

Technique:Cold Drawing

Treatment:Hydrogen Annealing

Condition:Soft Annealed

Certificate:ISO9001, SGS

Delivery Time:7-20 Days

Tensile Strength:630-780

Ocr25Al5 Wire

Delivery & Enquiries:

Most items are available for delivery in 3 to 7 working days. However, Ts heater do offer additional emergency services for customers who are in a breakdown situation. This includes a 48hr services on Mica products, Cartridge Heaters and Ceramic Knuckle Heaters. For all enquires please contact a member of our sales team who will be happy to assist.

Our corporation has a excellent assurance program are actually established for 2.0mm Thermal Spray Wire Ferrum Based Wire Ocr25al5 for Boiler Tubes& Tube Shilds. We hope to achieve mutual benefit and win-win under the premise of honesty and create common commercial value and social benefits. We have a good reputation, rich experience, competitive price, best service and a strong sales network.