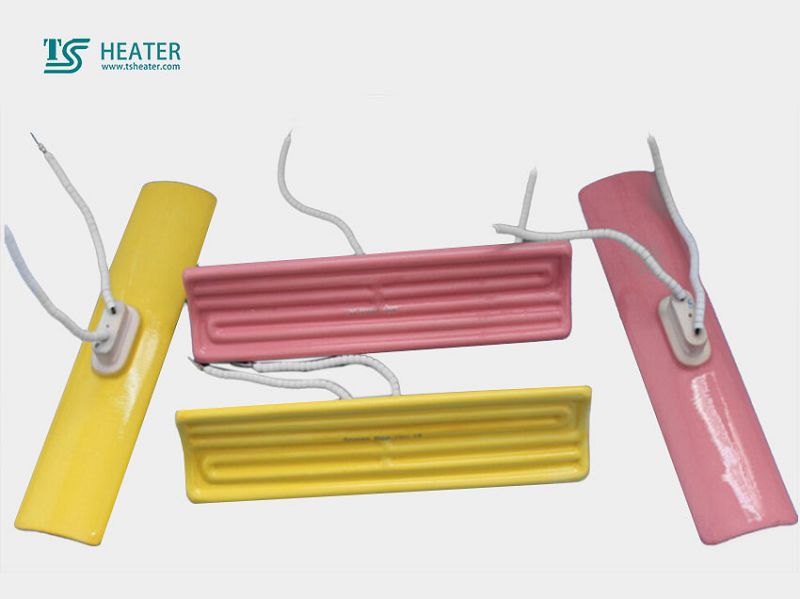

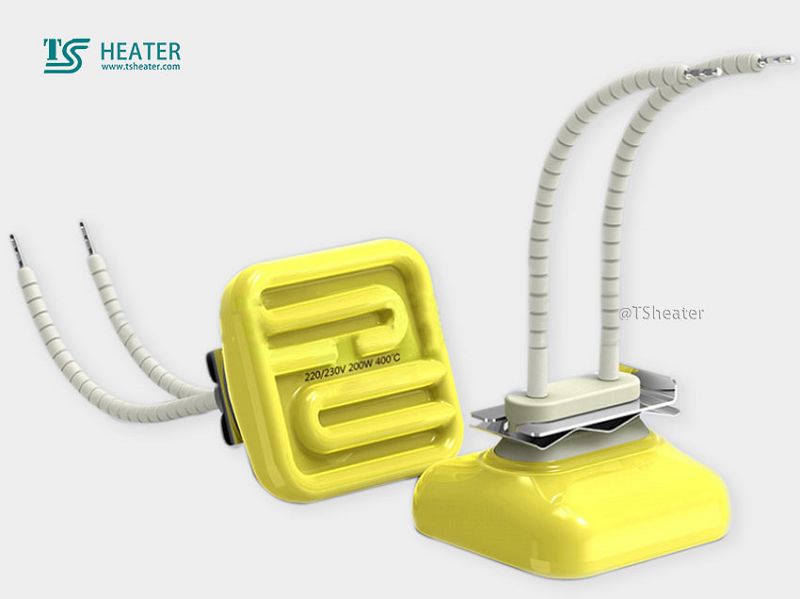

Infrared Ceramic Heaters It is the resistance wire Cr20Ni80 for heating, ceramic insulation and thermal conductivity.Resistance wires are cast into ceramics and then fired at high temperatures.Infrared Ceramic Heaters

We will continue to deepen cooperation, innovate and develop more high-quality coil winding machine, pelonis disk furnace, barrel heater blankets. Excellent quality, reasonable price and customer satisfaction are always pursued! With the core culture of 'helping customers and achieving ourselves', we insist on technological innovation, research and develop new products, and meet the needs of global customers with strong supply capabilities and stable product quality. We develop the best advantages and potential of each part of the enterprise, and constantly test the enterprise in order to be more perfect. We are ready to share win-win corporation.

Infrared Ceramic Heaters

Ceramic heating tile, it is used resistance wire Cr20Ni80 as heating element.

High emissivity glazes and ceramics with good thermal shock properties are insulators and thermal conductors.

Resistance wires are cast into ceramic and then fired at high temperatures.

1. Matrix: composed of ceramic materials with good thermal shock properties;

2. Heating property: it is made of high-quality ni-Cr alloy wire;

3. Glaze layer: it is composed of metal oxide raw materials with good outer radiation performance and appropriate additives are added to improve the radiation intensity and enhance the adaptability of the green glaze

Features:Infrared Ceramic Heaters

Heater has high emissivity, good overall performance, uniform heating, high insulation temperature, clean sanitation, long service life, corrosion resistance, oxidation resistance and other characteristics, surface load up to 6W/cm2.

General specifications: 60mm*120mm, 120mm*120mm, 240mm*60mm, 240mm*120mm, etc.

Special specifications required can be customized according to customer requirements.

Notes for use:Infrared Ceramic Heaters

1. Ceramic heating tile is not waterproof structure, so do not contact with oil, water, plastic particles when storing and using installation, to prevent electricity leakage.

2. The ceramic heating tile must be closely fitted to the heated body during installation. The surface of the heated body should be flat and complete without any uneven phenomenon.

3. Ceramic heating tiles in the use of such as found that the surface of the blackened color, it indicates that the heat and heat body heat imbalance, should be timely adjusted to prevent burning through.

Product performance:Infrared Ceramic Heaters

1. Radiation characteristics: the monochromatic emissivity of the element is up to 0.9, and the normal total emissivity is greater than 0.83.

2. Thermal response time: no more than 20 minutes from room temperature to constant value of radiant panel surface temperature.

3. Resistance to alternating heat and cold: no spalling or cracking after five alternating heat and cold tests.

4. The cold insulation resistance:

Ceramic Heater Plate Applications

· Animal Warming

· Curing

· Food Production Processes

· Food Warming

· Heat Treating

· Moisture Removal

· Non-Contact Heating

· Paint Drying

· Plastics Heating

Delivery&Package

1) Lead time:3-7 days after payment

2) Delivery Term: FOB,CIF

3) Shipping Mode: Air, Sea, Express

4) Package: Carton box/wooden case

We are an energetic firm with wide market for 220V Ceramic Infrared Heater for Plastic IR Heating Element. Our technological content and added value are increasing day by day, and we have grown our own core technology. Wide selection and fast delivery for you!