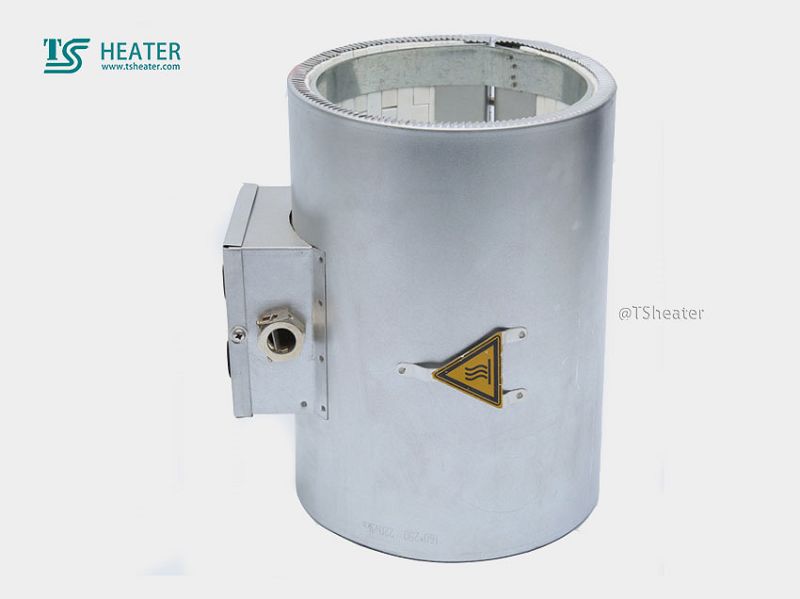

Ceramic band heaters are medium-to-high temperature heaters that have 600℃as a maximum working temperature. Electric Resistance Ceramic heater Bands provide long life and use less wattage (because of insulation) in plastics extrusion and injection molding applications.Electric Resistance Ceramic Heater Bands

Our corporation has a excellent assurance program are actually established for hot water immersion heater, silicone rubber sleeving, ceramic ir heater. The company sticks to the core value of 'cooperation and sharing', and we establish close strategic partnerships with relevant companies. It using the world's leading system for reliable operation, a low failure rate, it is suitable for customers choice. While we are putting quality first, we have also been providing honest service. For many years, we have been committed to customer satisfaction and strive to build our enterprise with our integrity and sincerity. We take the needs of customers as the basis for setting goals, and improve our ability and quality from the perspective of customers, and improve service quality.

Electric Resistance Ceramic Heater Bands

Ceramic band heaters are medium-to-high temperature heaters that have 600℃as a maximum working temperature. Electric Resistance Ceramic heater Bands provide long life and use less wattage (because of insulation) in plastics extrusion and injection molding applications.

Electric Resistance Ceramic Heater Bands

Ceramic band heaters are available with different terminal styles, are fully flexible, and can accommodate holes and cut-outs.TS heater engineering is available to assist with the design and development of special heaters for particular requirements.Electric Resistance Ceramic Heater Bands

Features:Electric Resistance Ceramic Heater Bands

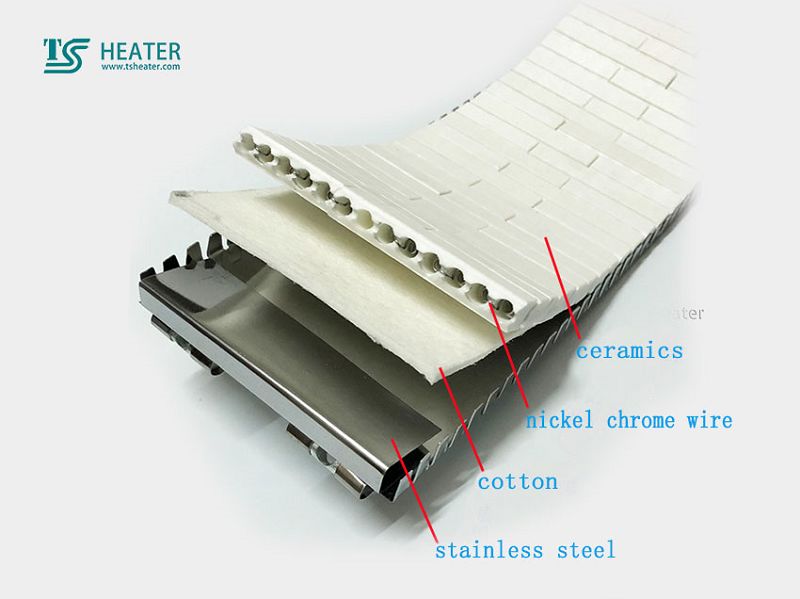

1.Stainless Steel sheath resists rust and high temperatures, and provides firm mechanical support.

2.Ceramic insulation prevents heat loss, thereby lowering energy costs.

3.High temperature nickel-chromium element wire

4.Reduce power consumption and conserve heat

5.High degree of flexibility

6.Uniform heat distribution

7.Various termination styles Customized

Application:Electric Resistance Ceramic Heater Bands

Injection molding

Blow Molding

Extrusion

Pipe and drum heating

Details sheet:Electric Resistance Ceramic Heater Bands

Product name | Ceramic Band Heaters |

Insulation Material | Ceramic Fiber Insulation |

Wavelength range | 2-10 Microns |

Max Wattage Density | 6W/cm² |

Wattage tolerance | +5%-10% |

Operating Temperature | 300°C-700°C |

Mini Diameter | 60mm |

Mini Height | 25.4mm |

Standard Thickness | 12mm |

Standard gap | 9mm |

Operating Life-Up | 20000 hours |

Huge stock,faster delivery:

Common band hearers:

Advantages of ceramic band heater:

Electric Resistance Ceramic Heater Bands

1. Fast heat transfer, uniform heat generation and stable operation.

2, The temperature does not leak, can save energy, the cover is not hot by hand, work safe.

3, The power of the product is high, the power of the ceramic strip is 0.5~1.5 times higher than the ordinary one.

4, Europe and the United States high temperature heating wire, with fast heat dissipation, uniform heating, high temperature stability, etc., can be used at 600-800 °C for a long time.

5, The product has a long service life, because the raw materials are slow to age at high temperatures, so the product has a long service life.

6, In line with the national GB technical requirements. Power deviation +5% ∽-10%.

7, Electrical strength: 1500v / 50Hz sinusoidal AC voltage test, no breakdown through 1MIN phenomenon.

8. High mechanical strength, good thermal insulation performance, large contact surface with heated objects and long service life.

9, Easy to install, maintain, the use of low cost, even if the internal heating material is damaged, and the external ceramic devices can still be reused.

Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for 35X50mm/35X70mm Stainless Steel Mica Band Heater Electric Heating Element for Plastic Injection Molding Machine Can Customize. We keep up with the world's leading edge of science and technology and strengthen independent innovation and strive for improvement. Our company assures you that our products are in high quality and proper component, and the product inspection certificate is also available.