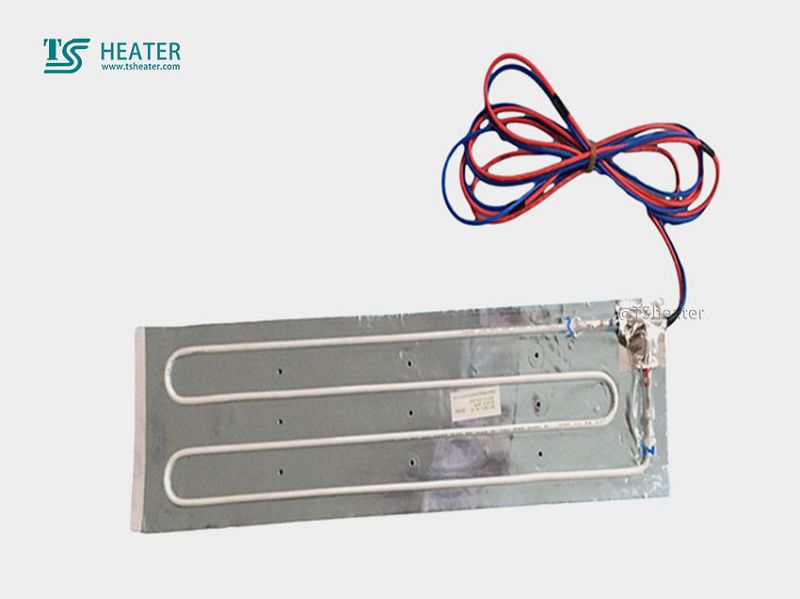

Refrigerator Defrosting Aluminum Pipe Voltage and power (voltage is determined by connection mode and rated voltage;The power depends on the heating medium and size. Please consult the sales staff for details.)Refrigerator Defrosting Aluminum Pipe

The programmable thermostat, tubular heater, electric tubular heater we produce have the advantages of long service life, reasonable structure, beautiful appearance, novel styles, and first-class quality, which is a new generation of products with strong vitality. Comprehensively improve the company's process and information construction level, strengthen the organization ability of resources and the ability of value-added services to the industry. We believe with our consistently excellent service you can get the best performance and cost least goods from us for a long term.

Applications: Refrigerator Defrosting Aluminum Pipe

1. Voltage and power (voltage is determined by connection mode and rated voltage;The power depends on the heating medium and size. Please consult the sales staff for details.)

2. Pipe diameter (generally 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, etc.)

3. Whether fastener is included, such as fastener, fastener size and thread length

4. Appearance material selection: the main materials are 10# carbon steel, SUS304, SUS321, SUS316L, stainless steel coating (scale prevention treatment), SUS310S(commonly known as: 2520), titanium tube, etc.

5. Material selection of heating wire: generally iron, chromium and aluminum wire (Beijing shougang), nickel and chromium wire (H140 and 2080 resistance wire, etc.).The choice depends on the client's working environment (temperature and vibration).

Points to note when using electric heating tube :Refrigerator Defrosting Aluminum Pipe

1. Electric heating tube is allowed to work under the following conditions:

(1) Air relative humidity is no more than 95%;

(2) The working voltage shall not be greater than 1.1 times the rated value, and the enclosure shall be effectively grounded.

2. When the heating medium is liquid, the effective length of the electric heat pipe must be immersed in the liquid.The heating part of the electric heating tube should be at a certain distance from the vessel wall, generally more than 50-60mm.

3. Electric heating pipes for heating liquids shall not be used for heating gases or solids.

4, Heating liquid components, such as found on the surface of the pipe scale or carbon, should be cleaned before use, so as not to affect the service life of the heating pipe and reduce the thermal efficiency.

5, Melting light metal or nitrates, alkali, asphalt, paraffin, etc. for solid state heating, should be voltage reduction start, until the solid state heating medium all melted before rising to the rated voltage.

6. Safety measures should be considered when heating nitrate to prevent explosion accidents.

7. The wiring part of the electric heat pipe should be placed in the insulation layer and outside the heating room, and avoid contact with corrosive and explosive gases.The outgoing end must be kept dry and clean to avoid flashover or short circuit.Do not apply too much force in connection.

8. A small amount of paste may spill out of the end of the heating tube. This is the sealing material, which will not affect the use.

9. Electric heat pipes shall be stored in a room with air circulation, relative humidity no more than 85% and no corrosive gases.

10. After the heating tube is used for a period of time and is not used for a long time, when its cold insulation resistance is less than 1 megabytic, the element can be baked in a drying box with a temperature of about 200 degrees, or the voltage can be reduced and heated directly on the power to remove moisture until it returns to normal.Refrigerator Defrosting Aluminum Pipe

Factory Show

Our heating elements and resistance wires are ideal for use in:

Small appliances; including space heaters, hair dryers, heat guns and heating pads

Large appliances; including refrigerators, freezers and dryers

Industrial ovens and furnaces for heat treating, melting, holding, burn-off or powder coating

Kilns

Duct heaters

Incubators

Medical autoclaves

Certificate:

Payment & Delivery:

Each of our 4 Half Door Gastronorm Vertical Restaurant Freezer with Auto Defrosting has undergone meticulous production procedures and strict quality control to ensure that every detail can reflect the spirit of ingenuity and meticulous pursuit. We have established and improved the system of production, sales and after-sales service to ensure the interests of users from all aspects, and maximize the benefits of customers with high-quality products and comprehensive services. We stick with the theory of 'quality first, company first, steady improvement and innovation to satisfy the customers' for the management and 'zero defect, zero complaints' as the quality objective.