Magnesium oxide ceramics are ceramic materials that contain at least 90% magnesium oxide (MgO).

It has good mechanical strength and works well when uniformly heated or cooled and thermal shock is avoided.

We hope to develop more humane products, and continuously inject high-quality and humanistic spirit into every coil bolt heater, ssr relay, ptfe immersion heater we develop. We will further play our advantages, improve production efficiency and provide high-quality and efficient services for customers at home and abroad. Relying on the support of friends from all walks of life, our company continues to develop the market with a development perspective, is going to occupy the market with a good reputation! Our company adheres to the business philosophy of 'customer first, forge ahead' to provide our customers with high-quality services. Our products are not only sold well in the national market, but also popular in many countries. The continuous improvement of the company's performance, the improvement of employee's treatment and the guarantee of welfare, all these are due to the high-quality employees.

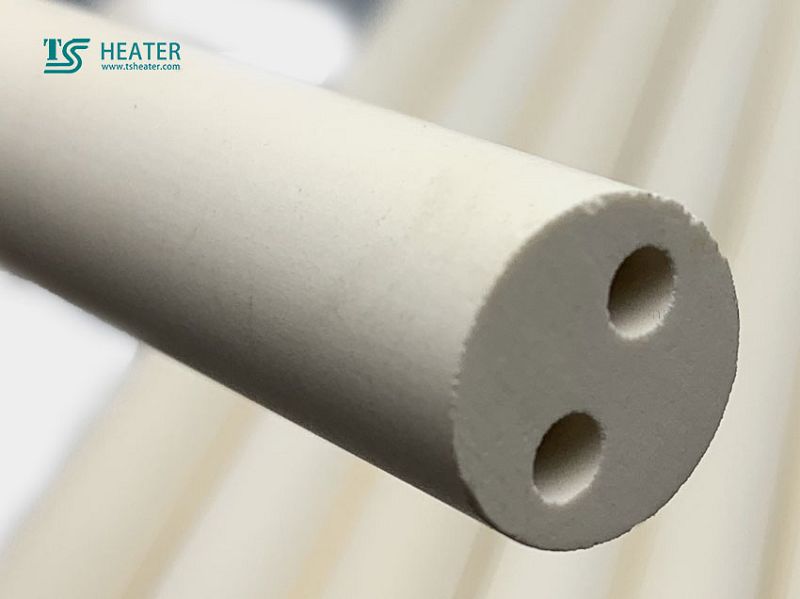

Material introduction:

Magnesium Tube Resistance

Magnesium oxide ceramics are ceramic materials that contain at least 90% magnesium oxide (MgO).

It has good mechanical strength and works well when uniformly heated or cooled and thermal shock is avoided.Performance is better than alumina, stable at 2200℃.However, above this temperature creep occurs.Because of its resistance to lead-based materials, it is used in the processing of piezoelectric materials.

Magnesium oxide tube magnesium oxide bar is used for heater

Features

Magnesium Tube Resistance

1. The ability to heat up.

2. Low conductivity.

3. High thermal conductivity.

4. Good corrosion resistance.

5. Infrared transparency

Details

Magnesium Tube Resistance

Type:Ceramic Rods

Application: Refractory, Industrial Ceramic

Model Number: magnesium oxide ceramic rod

Brand Name: MOEC

Name: magnesium oxide ceramic rod

Color: yellow

Size: Customers' Requests

Density: 3.2g/cm3

Material: magnesium oxide

Feature: High Temperature Resistance

Usage: Industry Usage

Shape: ROD

Working Temperature: 1400

Diameter*hole dia length:200\250\300 | ||||||

Φ3*0.7 | Φ5*1.2 | Φ8*1.9 | Φ11*2.4 | Φ14*3.2 | Φ17*4.0 | Φ20*5.0 |

Φ3.5*0.7 | Φ6*1.5 | Φ9*2.1 | Φ12*2.6 | Φ15*3.4 | Φ18*4.0 | |

Φ4*0.8 | Φ7*1.7 | Φ10*2.3 | Φ13*3.0 | Φ16*3.7 | Φ19*4.5 | |

Delivery & Enquiries:

Most items are available for delivery in 3 to 7 working days. However, Ts heater do offer additional emergency services for customers who are in a breakdown situation. This includes a 48hr services on Mica products, Cartridge Heaters and Ceramic Knuckle Heaters. For all enquires please contact a member of our sales team who will be happy to assist.

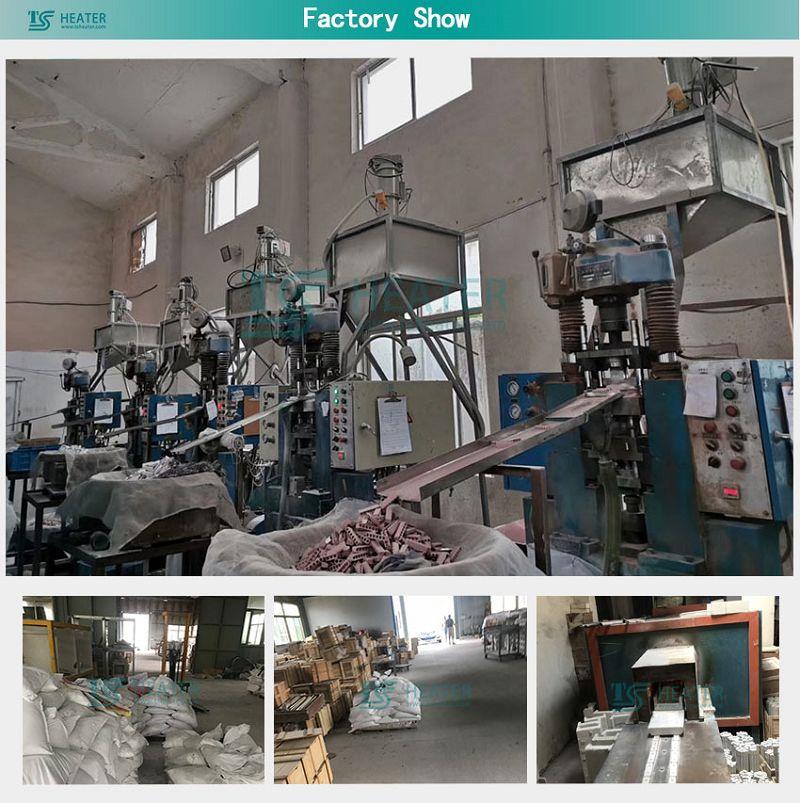

With our advanced equipment and exquisite workmanship, we focus on the development and production of 98.3---99.9% MGO Magnesia Ceramic Pipes Tubes Pin Rod through continuous practice and innovation. We have a simple, fast and efficient work style, and provide customized services that meet the individual requirements of customers. We strive for the goal of 'being an industry leader'! In the future, we will keep pace with the times, continue to introduce talents, improve the management mechanism, providing users with better products and better services!