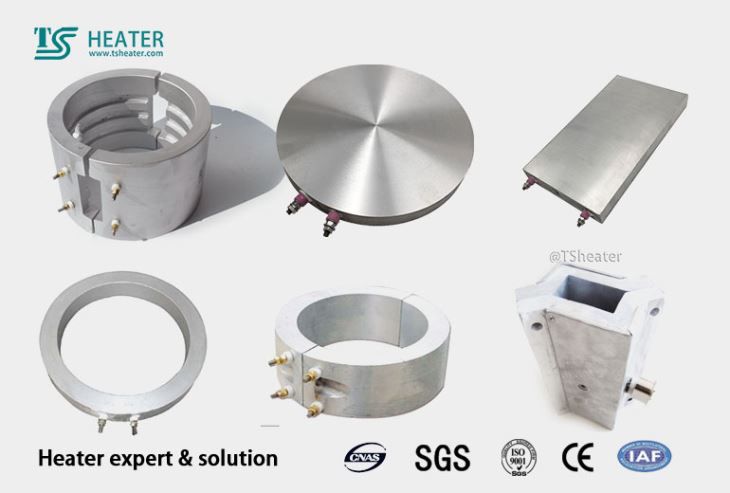

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round,Aluminum Casting Heater

We will strictly abide by our commitments, be proactive, further increase investment in research and development of 12 volt water tank heater, tubular electric heater, hot rod heater, develop better products to share with users, and sincerely provide quality services to users. The effective operation of our quality system has enabled the company's product quality to be steadily improved. We hope to build a world-class enterprise with global competitiveness under the guarantee of the modern enterprise system with our own characteristics. We sincerely invite people of insight from all over the world to accept the advanced technology. Our company adheres to the development direction of science and technology, pays close attention to the development trend of international industry, introduces international advanced technology, equipment and management experience.

Aluminum Casting Heater

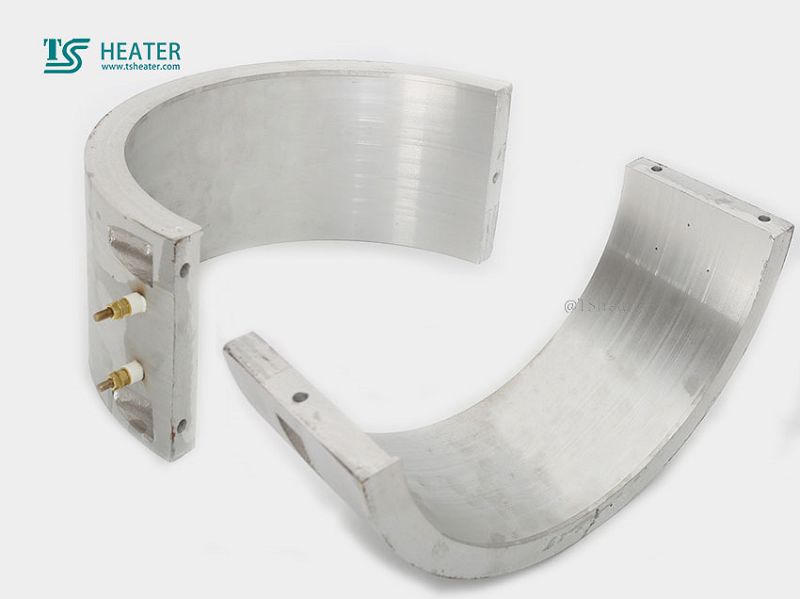

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round, flat, rectangular, air-cooled, water-cooled and other special-shaped etc..

Aluminum Casting Heater

After finishing it and heated body tightly, Metal casting heater is a kind of high efficiency heat uniformity division of the heater, thermal conductivity, excellent metal alloy, ensure the hot surface temperature uniformity, eliminating equipment hot and cold spots. With long life, good insulation properties, mechanical properties, corrosion resistance, magnetic resistance etc..

Aluminum Casting Heater

The outer radiating surface increases thermal insulation device, within the radiating surface of sintering infrared which can save 35% of electricity

Feature:

Aluminum Casting Heater

1.Cast aluminum surface load can reach 2.5-4.5w / cm2, maximum operating temperature 400-500 °C;

2.Cast copper surface load can reach 3.5-5.0w / cm2, maximum operating temperature 600-700 °C;

3.Cast iron surface load can reach 4.5-6.0w / cm2, maximum operating temperature 800-850 °C.

Customers’s cast in heater,ready to send out:

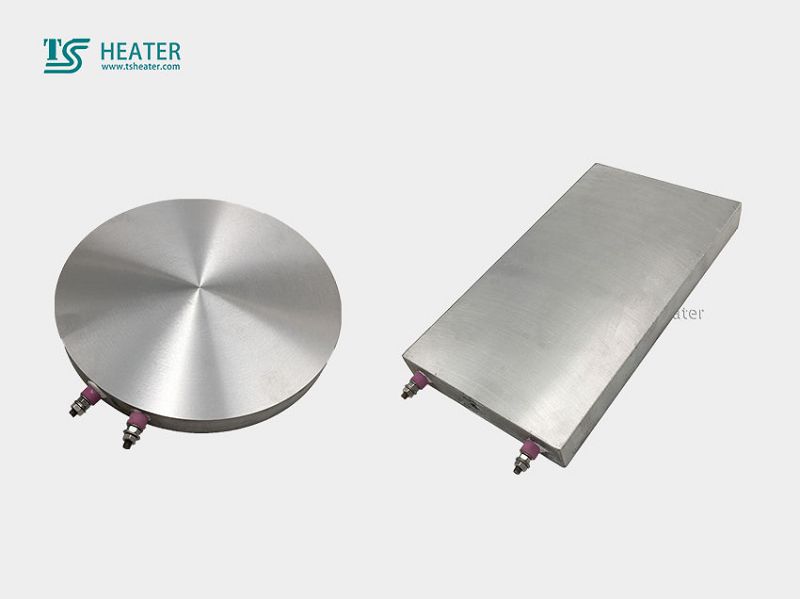

Our clients can avail a variety of Cast Aluminium Plate Heater from us. These plate heaters are designed by engineering experts working with us to suit requirements of different types of industries and client. These heaters are constructed using high-class aluminium which is procured from reliable vendors. Our heaters are highly praised for its complex designs and durability. We also offer customized solutions of these heaters understanding requirements and specifications of clients.

Our company mainly deals in Aluminum Low Pressure Die Casting, and can also develop and design related products according to customer requirements. Our company has been committed to the development of global customers, aiming to establish a long-term partnership. We are committed to building meaningful, inclusive and empowering corporate values, and strive to letting this open, global, and innovative ecosystem release unlimited possibilities.