Submersible Oil Heater,The surface power of the heating tube is 5.6w/cm2, which is suitable for liquid heating with good fluidity, less solid deposition and no crystallization of the liquid on the surface of the electric heater after cooling.

Since our establishment, we have adhered to the road of technological innovation, continuously committed to the research and development of 2kw immersion heater, dimplex thermostatic tubular heater, silicone mat for iron, and invested a lot of money in technology, equipment and modern management. We uphold the positive, honest, and pragmatic spirit of enterprise, constantly improve the company's own brand and value, and provide our users with high-quality services from beginning to end. Since its establishment, our company has been adhering to the sustainable development goal of the best combination of corporate environmental management, product environmental performance and market demand.

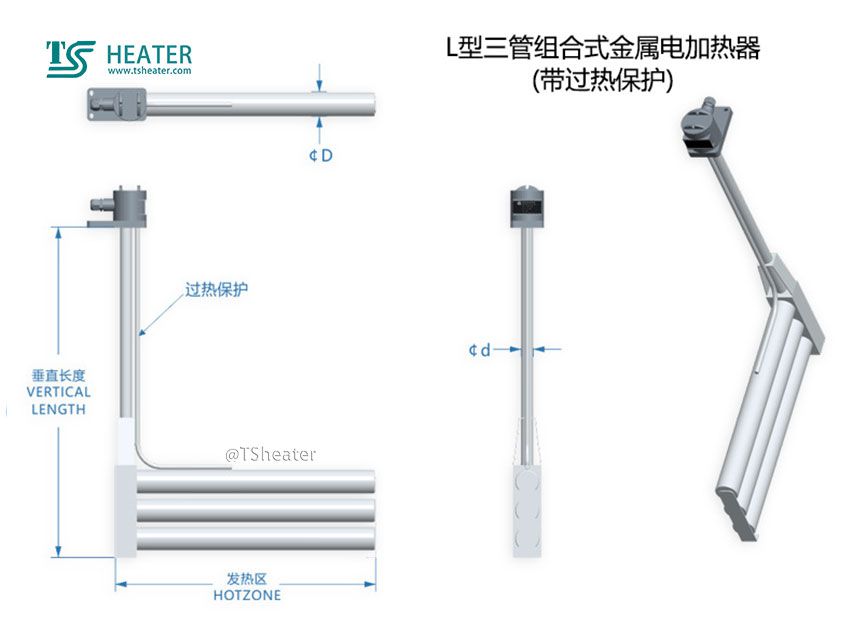

1. Titanium, zirconium, SUS304, SUS316 stainless steel tubes are used.

2. Design the surface power of the heating tube and determine the pipe diameter according to the installation location, chemical liquid properties and solid substance deposition characteristics in the liquid. Common specifications for pipe diameter are Ø 11 mm, 17 mm, 25 mm, Ø Ø Ø 30 mm, Ø 32 mm and 45 mm, Ø Ø 50 mm.

3. Submersible Oil Heater, liquid heating, heating tube surface power 5.6 W/cm2, suitable for liquid and solid deposit less, not in the heater surface cooled liquid crystalline liquid heating.

4. 45 mm diameter Ø series of products with low power design surface, good durability, especially for horizontal heating circuit board.

5. The voltage is 120V single-phase, 220V, 380V, 220V three-phase, 380V three-phase, power from 0.5kW to 140KW.

6. All heaters can be equipped with overtemperature protection switch or temperature sensing probe.

7. All heaters adopt international inspection standards to ensure safe electrical performance

Applicable environment: all kinds of electroplating corrosion liquid, due to the difference in steel selection.

Specification design: you can refer to the list of common specifications, or according to customer requirements to design various shapes, specifications, processes, etc.

For details, please consult our engineers and technicians

We focus on environmental friendliness, that is, we insist on manufacturing green Boiler Replacements Parts Center Tube Barrel for Power Plant Circulating Fluidized Bed Boiler Whirlwind Cyclone Separator and building green industrial chains to achieve sustainable development. Facing the new era, standing at a new starting point and starting a new journey, we are guided by the concept of integration, optimization, innovation, breakthrough and development. We are willing to cooperate sincerely with customers from all over the world and regions to create a better future with a complete quality assurance system and strict and orderly modern management.