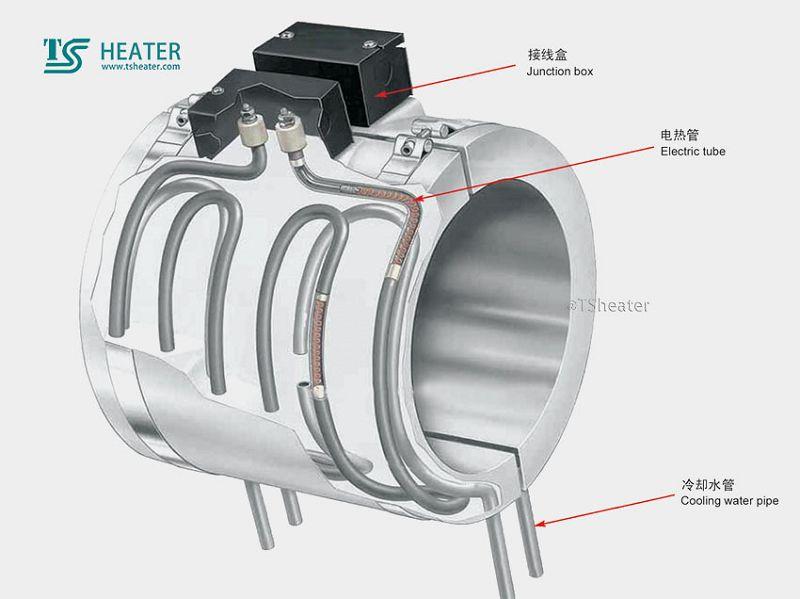

Cast aluminum heater is mainly used for extrusion and casting moulding machines. It has a wide application in various machinery industries. The operation temperature can reach up to 300°C (Aluminium).Cast Aluminum Heaters

The complete variety, novel design, and excellent quality of our high temp electrical wire, heating element for hot water heater, electric fin tube heater have impressed our customers both at home and abroad. We provide comprehensive pre-sale, after-sales service programs, we provide customer-centered service programs. In the context of economic globalization and the implementation of the 'One Belt, One Road' strategy, we have become an international company with the development philosophy of openness, tolerance, cooperation and win-win. To acquire a consistent, profitable, and constant advancement by getting a competitive advantage, and by continuously increasing the price added to our shareholders and our employee.

Cast aluminum heater is mainly used for extrusion and casting moulding machines. It has a wide application in various machinery industries. The operation temperature can reach up to 300°C (Aluminium).

Cast Aluminum Heaters

In order to concentrate the heat to one direction on the injection face, the other sides of the casting heaters t are covered by heat retention and heat insulation materials. So it has advantages such as advanced technology, high heat retention, long lifetime, anti-pollution, etc.

It is widely used in plastic extrusion, chemical fibre, blowing moulding machines.

Technical Parameters

Cast Aluminum Heaters

1. Conditions of use: ambient temperature -20 ° C ~ +60 ° C; relative humidity < 80%.

2, Electrical strength: can pass the voltage 1500V50HZ sinusoidal AC voltage withstand test, 1M1N without breakdown phenomenon under pressure.

3. Leakage current: <0.5MA.

4. Insulation resistance: >2MΩ.

5. Grounding resistance: <0.1Ω.

6, Power deviation value: +5% ~ -10%.

7, Temperature resistance: installed on the surface of the machine can be nearly 400 ° C.

Advantage

Cast Aluminum Heaters

1.It can be closely attached to the heated body.

2.Uniform heating

3.Good thermal conductivity

4.Long service life.

Client’s order ready to ship out:

Order Guide:

Please specify the following when ordering.

The inner diameter (mm) and length (mm) of heaters

Thickness of heaters

Terminal length (max & min) and the distance of terminal length

The diameter, length of cooling tubes and the distance between them.

Voltage and power density

Gap of two pieces if applicable

Wiring type and position

Whether need air blowers

Content of the stamping if needed

Order quantity

Delivery date

* It's better to provide us with the drawings/pictures

Others: position of terminal box, the position and size of the hole for connecting thermocouple OR of the incision, whether need to cast in the terminal

We insist on being customer-centric and creating value for customers through rigorous services and products. As a manufacturing expert of Cast Aluminum Heater and Fan for Injection Die and Mold, we are committed to bringing you more convenient experience and more considerate service! In recent years, we have achieved not only the increasing strength of the team, but also the growth of brand influence. We always practice the corporate philosophy of integrity management, innovative development, and service to the society striving to become an internationally competitive brand enterprise.