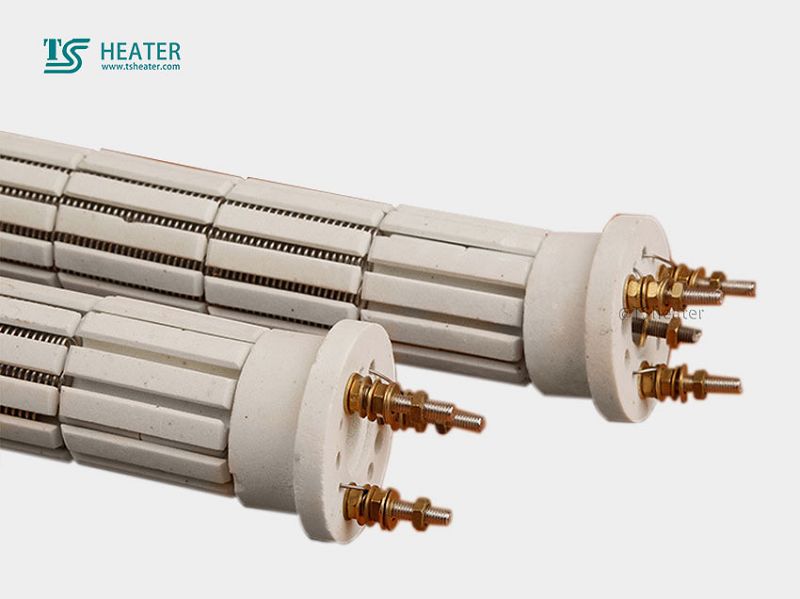

Hot Air Ceramic Bobbin Heater Ceramic parts as the framework, inlaid by nickel-chrome wire, jacket special sheath, can truly achieve water and electricity separation, do safe and reliable.Compared with conventional metal tubular heating elements, it has the following advantagesHot Air Ceramic Bobbin Heater

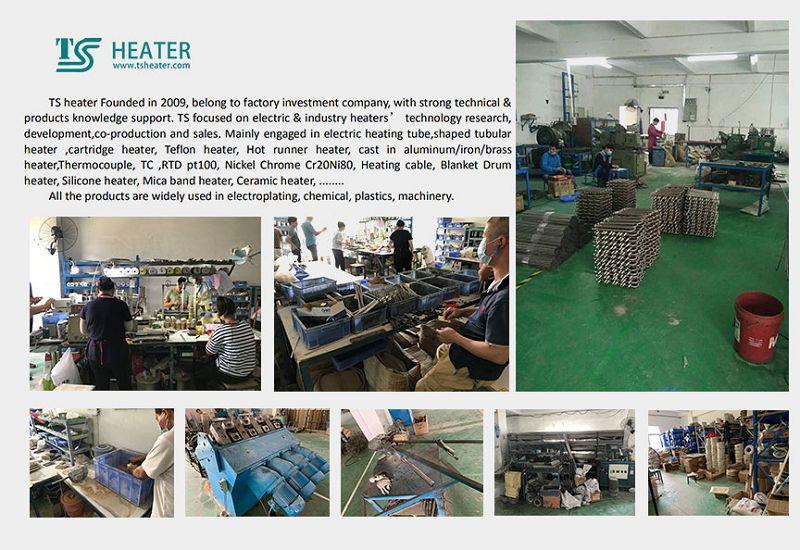

We have established a complete set of quality assurance system to ensure that our mica heater, electric tubular heater, rtd temperature can meet market norms and requirements. We take 'internationalization, specialization, and quality' as our development goal, and win customers with our passion, focus and sincerity. We strive to show our own unique qualities different from others, that are responsibility, openness and decision-making.

Hot Air Ceramic Bobbin Heater Ceramic parts as the framework, inlaid by nickel-chrome wire, jacket special sheath, can truly achieve water and electricity separation, do safe and reliable.Compared with conventional metal tubular heating elements, it has the following advantages:

The selection of unique materials can ensure that the components have good electrical performance under long-term working conditions.Hot Air Ceramic Bobbin Heater

The advanced design and reasonable structure make the element have the characteristics of high thermal efficiency, long service life, safety and reliability.

Special heating mode, coupled with anodic protection device, can greatly reduce the formation of scale.

The unique installation mode can make maintenance and replacement easier.

Material: corundum ceramics, high temperature resistance wire

Form: isometric

Hot Air Ceramic Bobbin Heater

Extra large voltage: 110-450 (V)

Power: according to customer demand (W)

Main application: for liquid heating, such as electric boiler, oil furnace, storage tank, chemical raw material heating furnace, air heating and other containers.

Main features:

Hot Air Ceramic Bobbin Heater

1. Safety: liquid and electricity are truly separated.

2. Convenience: when maintaining or replacing the heater, there is no need to stop the furnace and stop production, and no need to discharge the liquid in the container. The heater can be withdrawn for repair or replacement.

DIA MM | SUS PIPEmm | Length(mm) | Power design range kw/m | |

Water | oil | |||

φ31 | φ38×3 | 300-1500 | 4.5-5.5 | 3.5-4 |

φ44 | Φ51×3 | 300-2000 | 6-7 | 4-5 |

φ49 | Φ57×3.5 | 300-2500 | 7-8 | 5-6 |

φ62 | Φ70×3.5 | 500-3000 | 8.5-9.5 | 6.5-7.5 |

φ67 | Φ76×4 | 500-3500 | 9.5-10.5 | 7-8 |

φ68 | Φ76×3.5 | 500-3500 | 9.5-10.5 | 7-8 |

φ108 | Φ121×5 | 1000-6000 | 15-17 | 12-13 |

Packing and delivery:

Certificate:

We attempt for excellence, support the customers', hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Corrosive Heating Element Alumina Ceramic Bobbin Heater Tubular Heater. As we have customer centric approach, we have made frequent innovations in our products that further provide maximum satisfaction to our clients. We also offer customized products to meet the specific demands of our clients to achieve customer satisfaction. Our company requires the sales staff to keep zero distance contact with users all the time, provide customers with fast and high-quality service and meet the needs of customers with high-quality solutions.