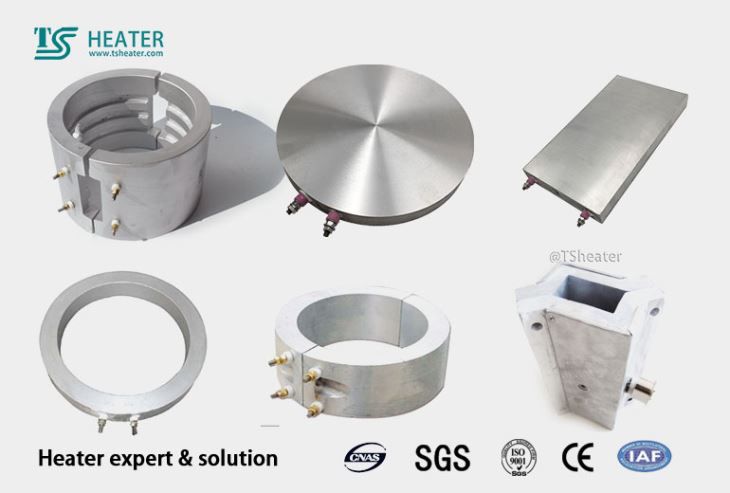

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round,Aluminum Casting Heater

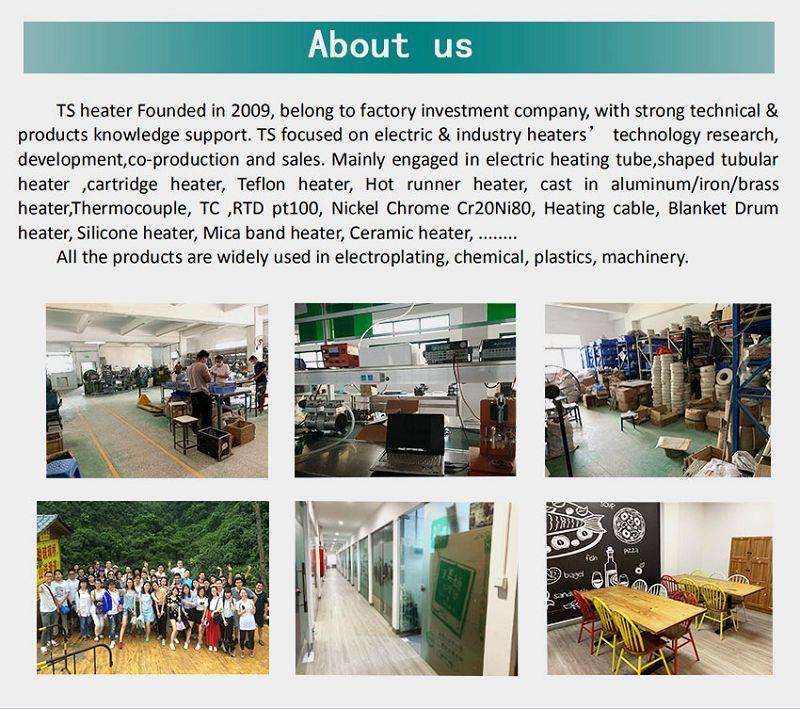

With a mission of 'Commitment to Excellence', our R & D team, with many years of experience in the field of cnc centerless grinder, air finned heater, aluminum heater, is constantly dedicated to improving the quality, performance and range of applications according to needs of customers. In the era of rapid change, we take advantage of leading technology, advocate the future with science and technology. We have noticed that with the economic growth, the industrial structure is accelerating the transition from simple labor-intensive products to capital and technology-intensive products and self-owned brands and self-developed products. Warm tips: the price of raw materials of our products will fluctuate, so the prices of finished products will be different. Sticking towards the principle of 'Super High-quality, Satisfactory service'.

Aluminum Casting Heater

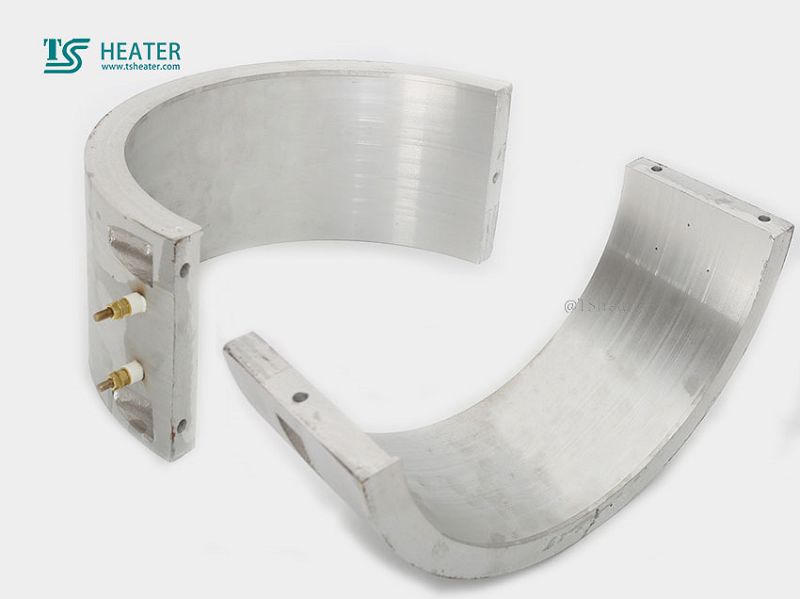

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round, flat, rectangular, air-cooled, water-cooled and other special-shaped etc..

Aluminum Casting Heater

After finishing it and heated body tightly, Metal casting heater is a kind of high efficiency heat uniformity division of the heater, thermal conductivity, excellent metal alloy, ensure the hot surface temperature uniformity, eliminating equipment hot and cold spots. With long life, good insulation properties, mechanical properties, corrosion resistance, magnetic resistance etc..

Aluminum Casting Heater

The outer radiating surface increases thermal insulation device, within the radiating surface of sintering infrared which can save 35% of electricity

Feature:

Aluminum Casting Heater

1.Cast aluminum surface load can reach 2.5-4.5w / cm2, maximum operating temperature 400-500 °C;

2.Cast copper surface load can reach 3.5-5.0w / cm2, maximum operating temperature 600-700 °C;

3.Cast iron surface load can reach 4.5-6.0w / cm2, maximum operating temperature 800-850 °C.

Customers’s cast in heater,ready to send out:

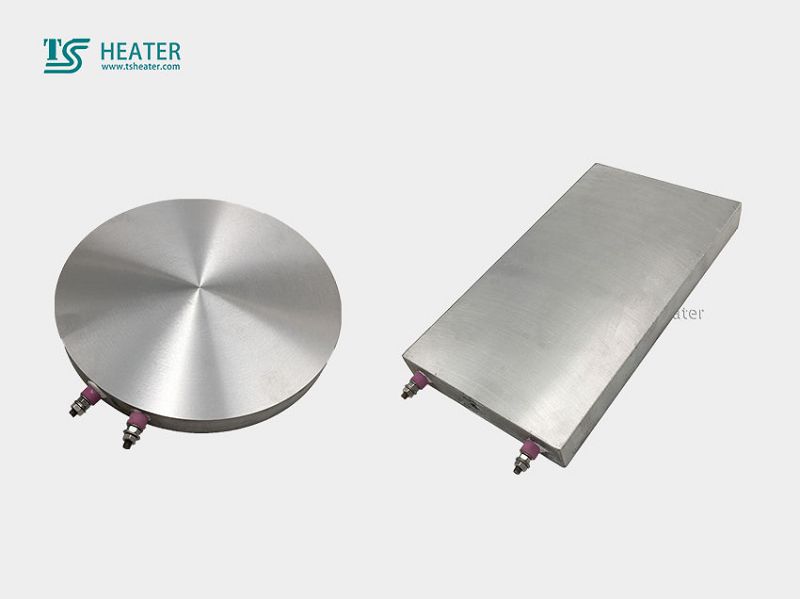

Our clients can avail a variety of Cast Aluminium Plate Heater from us. These plate heaters are designed by engineering experts working with us to suit requirements of different types of industries and client. These heaters are constructed using high-class aluminium which is procured from reliable vendors. Our heaters are highly praised for its complex designs and durability. We also offer customized solutions of these heaters understanding requirements and specifications of clients.

It is the customer's satisfaction with our products and services that has always inspired us to do better in this business. We establish mutually beneficial relationships with our customers and provide them with a large number of high-quality Customized Steel Mesh Deck with Waterfall by Galvanzied at low prices. Thanks for taking your valuable time to visit us and look forward to have a nice cooperation with you. We insist on making the best use of our talents and building a diversified management structure.