Depending on their rating, sheath and shape, industrial tubular heaters are used in a variety of industrial heating applications (conduction, convection, radiation heating) that require process temperatures of up to 750°C (1 382°F) to heat liquids, gases and solids.Industrial Tubular Heaters

In order to adapt to the development and requirements of the market, we intensified our research and launched new series of aluminum casting, strip heaters, mica thermic heater in line with customer needs. We can give you the most competitive prices and high quality, because we are much more PROFESSIONAL! We adhere to the business philosophy of reliable quality and customer first, and sincerely look forward to cooperating with you. Our industrial layout has been gradually optimized, our market advantage position has been consolidated, and our influence has been continuously enhanced, thus our development prospects are bright. The excellent technical strength and competitive market price not only win business opportunities for us, but also win the trust and support of our customers.

Industrial Tubular Heaters

Depending on their rating, sheath and shape, industrial tubular heaters are used in a variety of industrial heating applications (conduction, convection, radiation heating) that require process temperatures of up to 750°C (1 382°F) to heat liquids, gases and solids.

Industrial Tubular Heaters

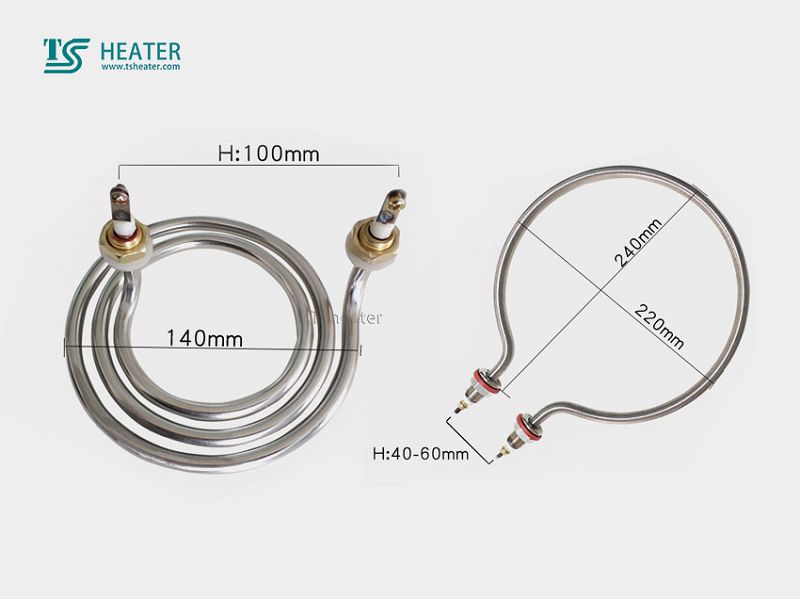

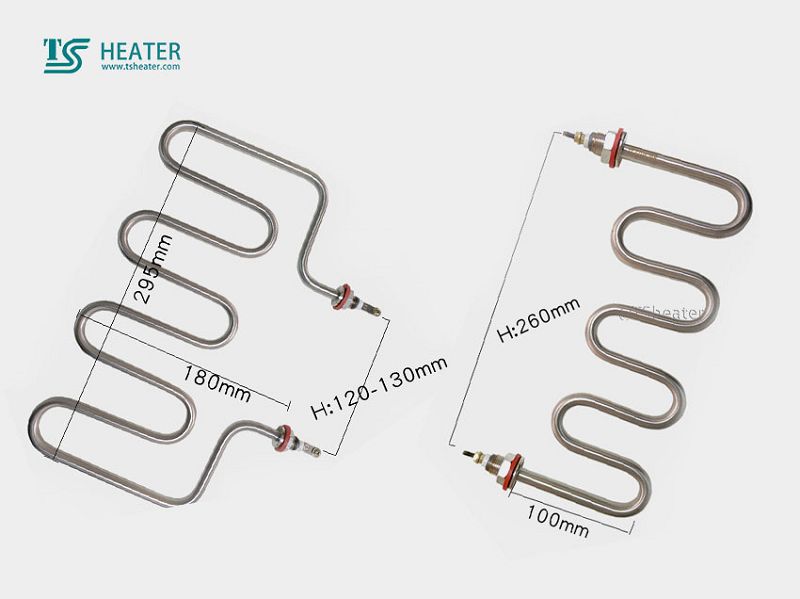

A variety of diameters are available to adjust watt densities in your application and to design your industrial heating product for best performance and long life. Standard and custom made terminal pins allow for easy installation and maintenance. TS heater uses high quality magnesium oxide to allow for efficient heat transfer from resistive coil to your heating medium whether it is air, liquid or solid. Bending radiuses are designed with careful expertise to allow for optimal performance when meeting “form fit and function” within your application,Industrial Tubular Heaters

Specifications: Industrial Tubular Heaters

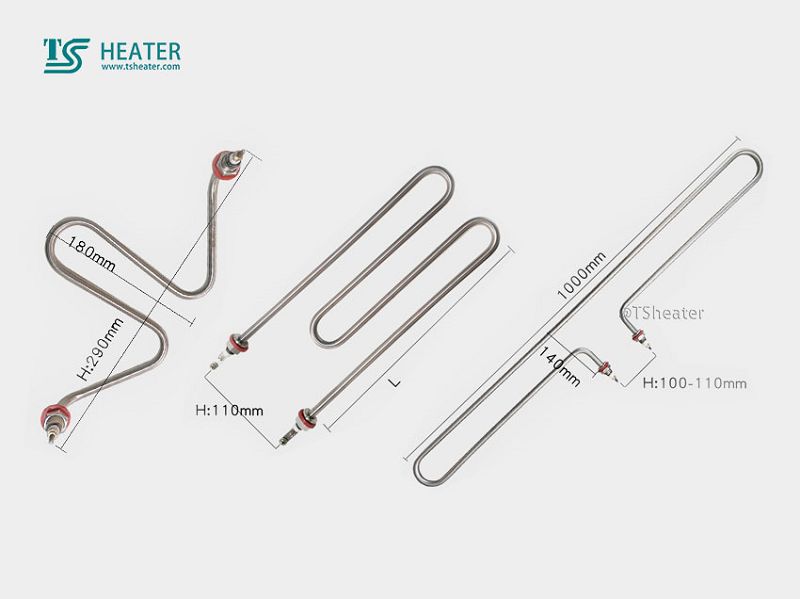

1.Standard diameters: 0.260 inch , 0.315 inch , 0.375 inch , 0.430 inch , 0.475 and 0.625 inch diameters

2.Available in a broad variety of sheaths, diameters, and ratings

3.Supplied with electrically insulated sheath

4.Provide superior internal electrical insulation and heat conductivity

Benefits: Industrial Tubular Heaters

1.Easy to install

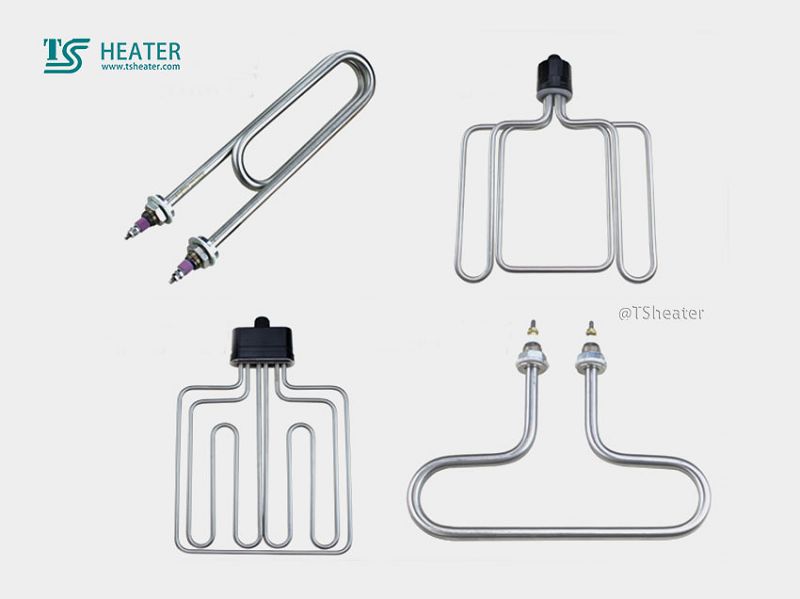

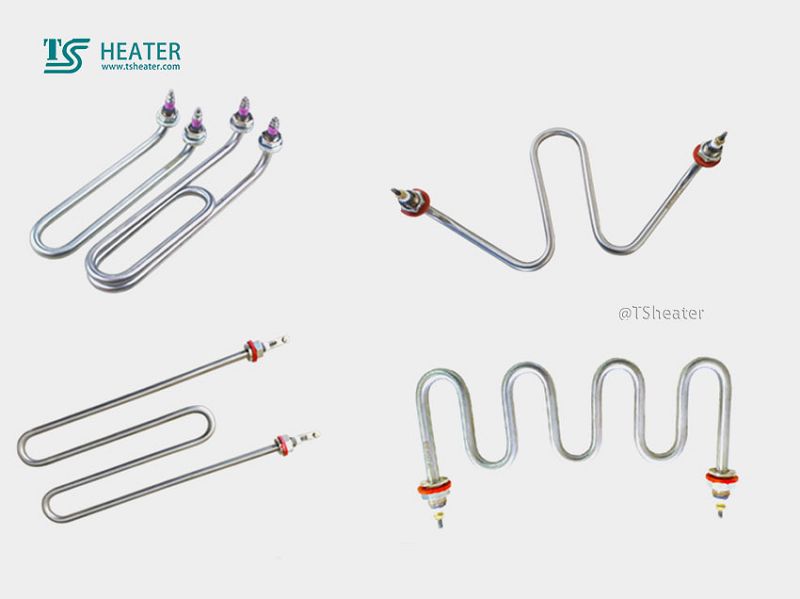

2.Configurable to virtually any shape

3.Compact size

4.Precise and easy control of heat output

5.Durable

6.Easy to maintain

7.Easy to replace thus eliminating long shut-down periods

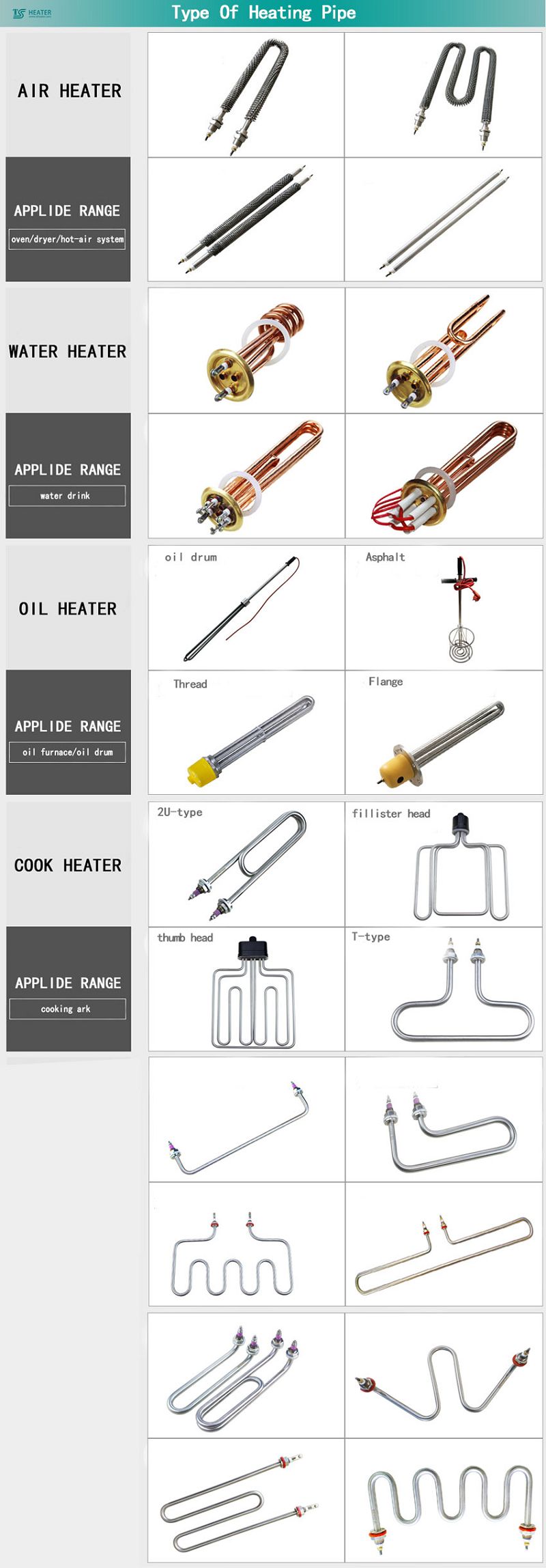

Type of industrial tubular heaters:

TS heater Founded in 2009, belong to factory investment company, with strong technical & products knowledge support. TS focused on electric & industry heaters’ technology research, development,co-production and sales. Mainly engaged in electric heating tube,shaped tubular heater ,cartridge heater, Teflon heater, Hot runner heater, cast in aluminum/iron/brass heater,,Thermocouple, TC ,RTD pt100, Nickel Chrome Cr20Ni80, Heating cable, Blanket Drum heater, Silicone heater, Mica band heater, Ceramic heater, ........

All the products are widely used in electroplating, chemical, plastics, machinery

We always insist on taking quality and technological innovation as the core competitiveness of enterprise development. We have won praises from customers all over the world for our excellent Electric Far Infrared Ceramic Heater for Drying quality and efficient service. We take the accumulation of resources and capabilities with a competitive advantage as our starting point, and aim to expand our scale and improve our efficiency. The scientific research and development system and the top-rate team are the guarantee of our innovation and development.