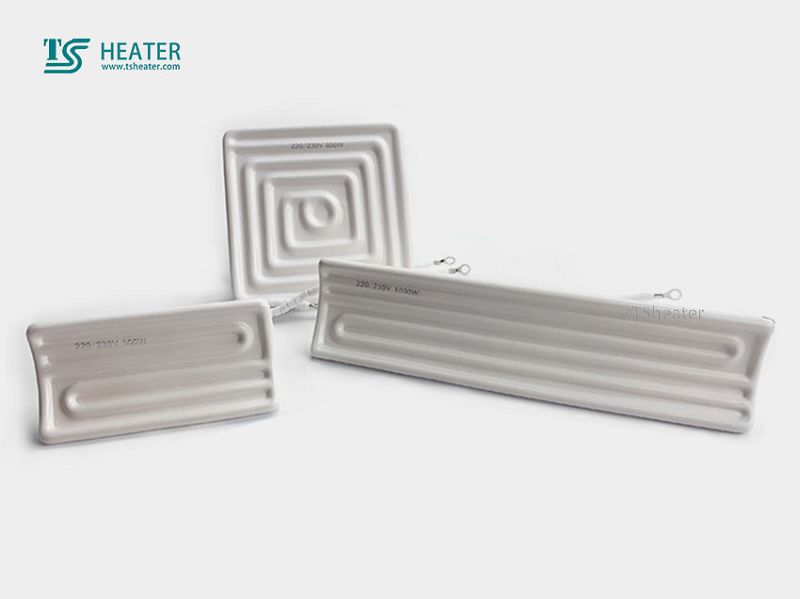

Infrared Ceramic Resistance Compared with traditional steam, hot air and resistance heating methods, far-infrared heating has many advantages, such as fast heating speed, good quality of new products, small area of equipment, low production cost and high heating efficiency.Infrared Ceramic Resistance

We investigate the production of coil heater, stainless steel pipe, mainstays ceramic tower heater, and take advantage of the strengths of many other manufacturers to innovate it continuously. In today's wave of economic development and fierce market economy competition, we cherish our hard-won honors and will make unremitting efforts along the road of industrialization, specialization and modernization. Our production have been exported to many countries and regions as first hand source with lowest price. We hope to mobilize the enthusiasm of employees, stimulate their creativity and enhance corporate cohesion. We follow our enterprise spirit of 'Quality, Efficiency, Innovation and Integrity'.

Infrared Ceramic Resistance Compared with traditional steam, hot air and resistance heating methods, far-infrared heating has many advantages, such as fast heating speed, good quality of new products, small area of equipment, low production cost and high heating efficiency.Use it instead of electric heating, its power saving effect is particularly significant, generally can save about 30% of the power, some occasions even up to 60% ~ 70%.

Their composition is as follows: Infrared Ceramic Resistance

1. Matrix: composed of ceramic materials with good thermal shock properties.

2. Heat: it is made of high-quality nickel-chromium alloy wire.

3. Glaze layer: group of metal oxide raw materials with good radiation performance from far away.

4. Add the right amount of additives to improve the radiation intensity and enhance the adaptability of the blank glaze.nguyen

5. Heat the substrate to 800℃ and place cold water for dozens of times without cracking.

Application: Infrared Ceramic Resistance

Buried ceramic far red radiation element is based on the guidance of advanced technology, coupled with years of research, the results.With high technology content, good overall performance, cleaning and sanitation, easy assembly, acid resistance, corrosion resistance, use, long life characteristics.Widely used in vacuum blister, food baking, medical and health and other infrared drying baking, curing and other occasions, in the electronic textile, light industry, mechanical and electrical chemical, medical, food and other industries has the ideal energy saving effect, has obvious social and economic benefits.

Can be customized according to customer's special requirements.Infrared Ceramic Resistance

Stock product:

To be a result of ours specialty and service consciousness, our company has won a superb reputation between customers all around the environment for Electric Infrared Ceramic Sauna Heater Tube. 'Perseverance, create excellence' is the spirit of our enterprise, 'integrity, service, win-win, development' is our business philosophy, we are willing to create the greatest profit margin for customers. Over the years, we have relied on our own technology to continuously innovate to increase the value of our products and lead the market to advance.