Water Tank with Immersion Heater : 1 100% guaranteed no leakage welding; 2. Excellent sealing performance; 3. Limited protection against safety accidents caused by heaters.

The testing hot water heater element, fin tube heater, teflon tape has excellent quality and reasonable price, since it was put into the market, it has been favored by users and caused great social repercussions. We provide comprehensive pre-sales, in-sales, and after-sales technical services to solve users' worries, because we deeply realize that only superior quality and good service are the greatest guarantee for customers. We insist on people-oriented, and hope to provide employees with a good working environment and incentive mechanism. Our company is committed to the interactive construction of the market with the concept of 'Quality as life, management yielding benefits, and science and technology for development'.

Advantages of Water Tank with Immersion Heater:

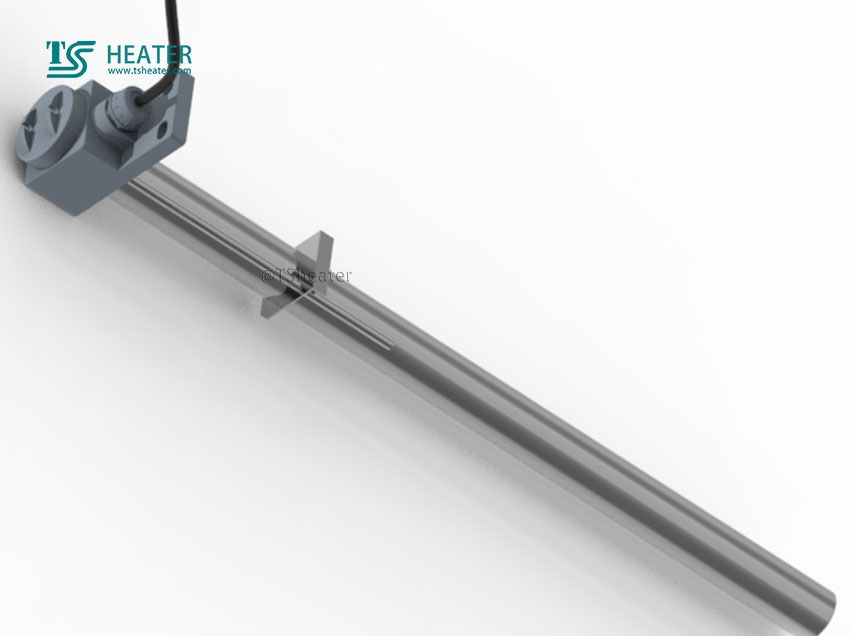

1. Automatic welding is adopted in the mouth, 100% guarantee no leakage welding;

2. Epoxy resin is used for sealing, with excellent sealing performance;

3. Ul94-v0 grade flame retardant wire connection box can effectively prevent safety accidents caused by heater;

4. Make the heater cable according to national standard to ensure that the heater will not cause fire accident due to excessive current;

Notes for use of Water Tank with Immersion Heater:

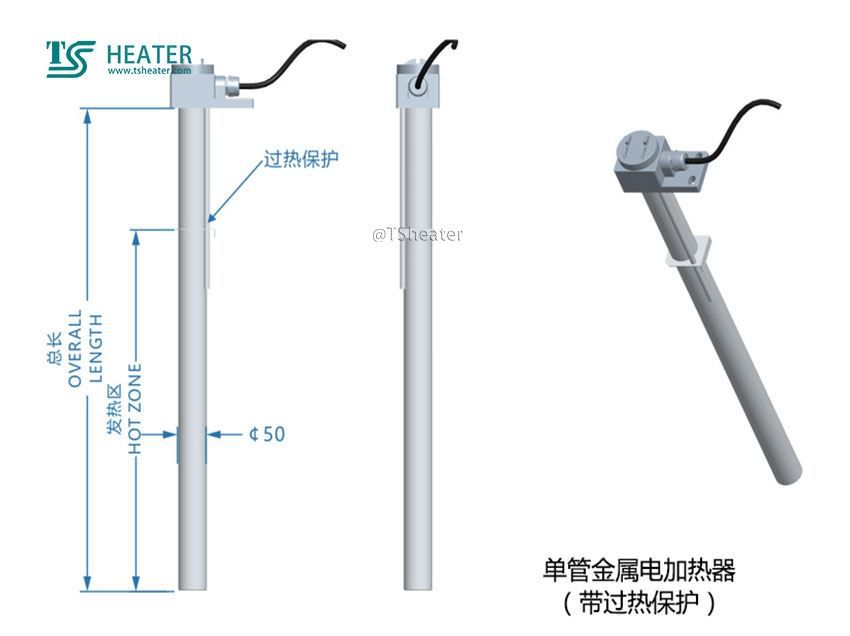

1. Temperature fuse: The temperature fuse device is in the casing tube next to the heater. When the liquid level drops and the temperature exceeds the safe value of the fuse, the fuse will be blown out, playing a protective role. The fuse needs to be replaced after it burns out. The temperature parameter of the fuse is 250V/5A 105℃ or 95℃

2.The Sensor is placed in the casing next to the heater. When the liquid decreases and the temperature exceeds the over-temperature point, the temperature will be turned on and the power will be turned off to protect the heater. When the temperature drops, the power can be switched on again. Temperature starting parameter: 250V/5A 105℃ or 95℃.

3. The reconnecting temperature of the temperature switch is 15℃ lower than the overtemperature point.

4. Due to the limitation of electrified flow, contactors are required for temperature fuses and temperature heads. It is not possible to directly connect the load of power supply and electric heater.

Quality assurance: all metal tube heaters can be guaranteed for one year in the case of non-human damage or wrong design, and can provide long-term maintenance services according to customer requirements.

The key to our success is 'Good Product or service High quality, Reasonable Rate and Efficient Service' for Electric Tubular Heater Heating Element. Our company has professional knowledge and rich experience in product development, production and application. Our technical staff can recommend suitable products according to the different needs of customers and provide them with perfect service. We are always striving for product technology, brand awareness and market share.