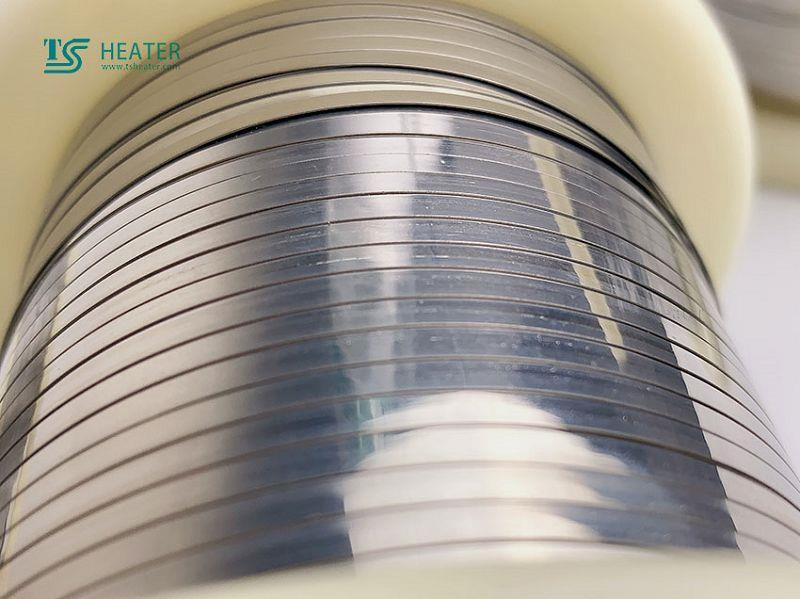

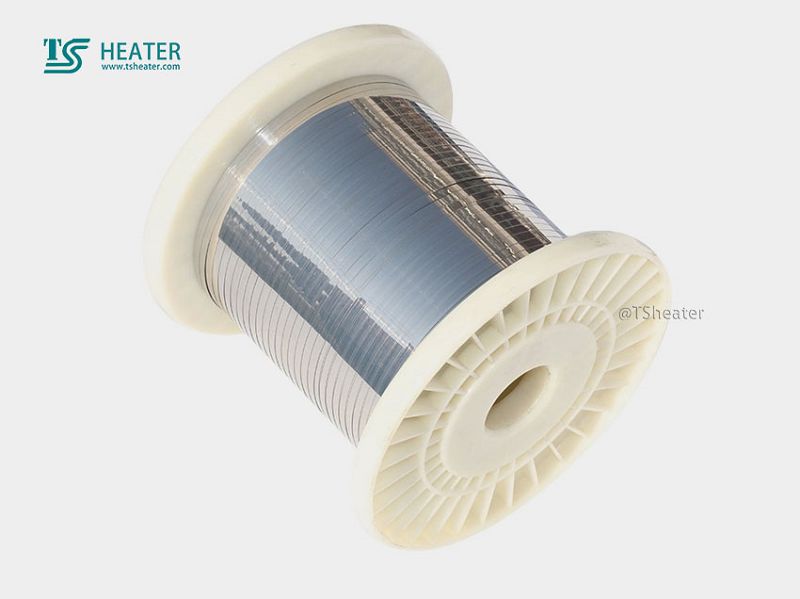

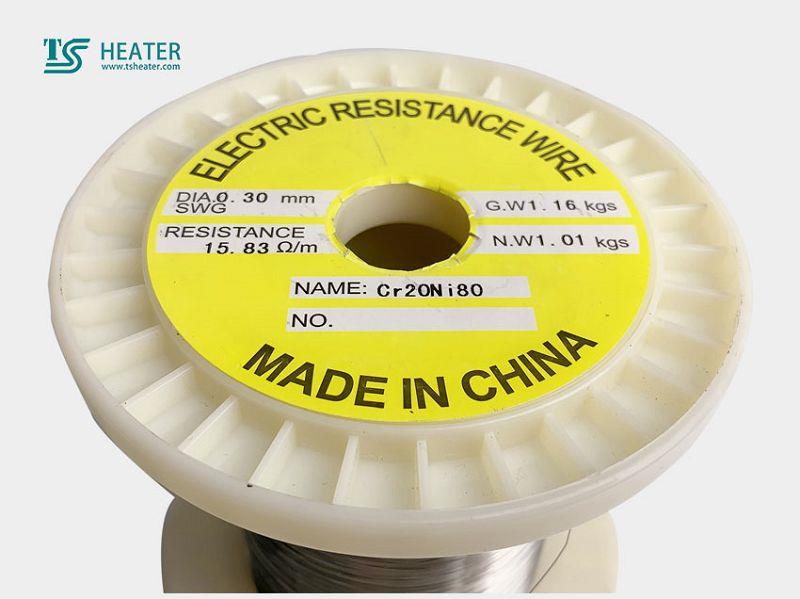

Cr20Ni80 is a resistant electric heating alloy. Stable microstructure and electrical and physical properties, good high-temperature mechanical properties, good cold deformation plasticity, good weldability, and long-term use without brittle fracture. The working temperature of Cr20Ni80 is below 1000℃, and the service life is long.

We seize strategic opportunities to strengthen our k type connector, dimplex tubular heater 80w, 24v heater cartridge's development and manufacturing. Our company is highly recognized by the industry for its integrity, strength and product quality, and has a complete production chain. Steady and pragmatic is the foundation of the survival and development of an enterprise, thereby we must combine development goals with practical actions and put our feet on the ground. Customer′s satisfaction and support are what we have been strived for. The perfect management, advanced equipment, and professional staff are the keys to win the favor of our customers.

Cr20Ni80 has excellent comprehensive properties. High-quality heating elements will choose Cr20Ni80. Cr20Ni80 has the advantages of good oxygen resistance, high strength, non-magnetic, high emissivity, good corrosion resistance, no softening, no deformation, and low permanent elongation.

Application range of Cr20Ni80:

1. As an advanced heating element, it is mainly used for periodic heat treatment furnaces whose operating temperature is below 1000℃, such as carburizing furnaces, bell furnaces, ammonia decomposition furnaces, etc.

2. It can be widely used in metallurgy, household appliances, machinery manufacturing, and other advanced heating elements and as advanced resistance materials in the electrical industry.

3. Used for resistance bands in high-quality resistance boxes.

4. It can also be used as high-quality heat-resistant steel structural parts, such as high-temperature mesh belts, burning racks, etc.

5. Using Cr20Ni80, it also represents the high-quality symbol of electric heating products

Paraments | Specification |

Type | Cr20Ni80 |

Chemical Composition | Cr:22%,Ni:Rest |

Max continue operating temp. (°C) | 1200 |

Resistivity (10-6 Ω.M) at 20°C | 1.09±0.05% |

Specific heat capacity at 20 °C J/gk | 0.440 |

Density at 20 °C (g/cm3) | 8.4 |

Melting temp °C | 1400 |

Elongation | 25 |

Microstructure | Austenite |

Delivery & Enquiries:

Most items are available for delivery in 3 to 7 working days. However, Ts heater does offer additional emergency services for customers who are in a breakdown situation. This includes 48hr service on Mica products, Cartridge Heaters, and Ceramic Knuckle Heaters. For all inquiries please contact a member of our sales team who will be happy to assist.

We recognize that we must improve the quality of Electrolytic Nickel/Nickel Alloy/Battery Ni/Battery Plate and increase product value in order to improve economic efficiency. We deeply feel that product quality plays an important role in improving corporate reputation and expanding market share. We use this as a new driving force for corporate management and make unremitting efforts to ensure that product quality continues to meet customer needs. We have built a reliable reputation among many customers.