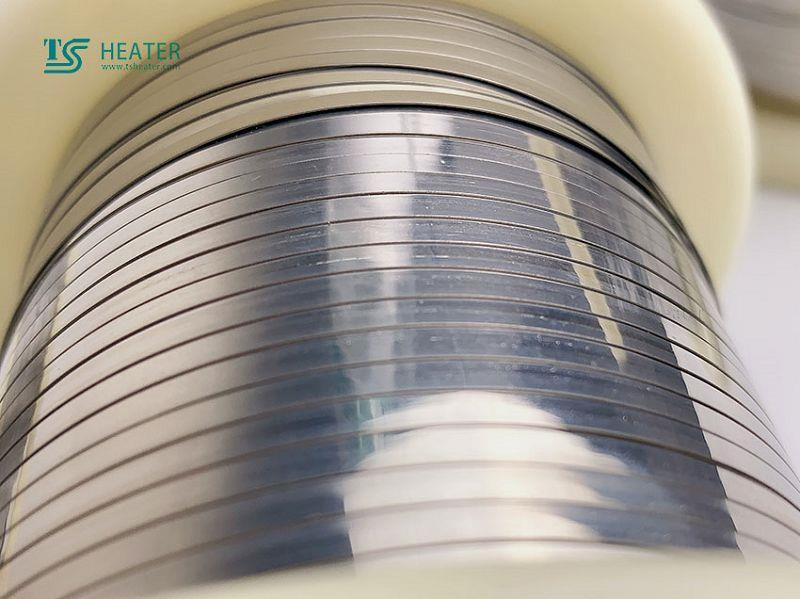

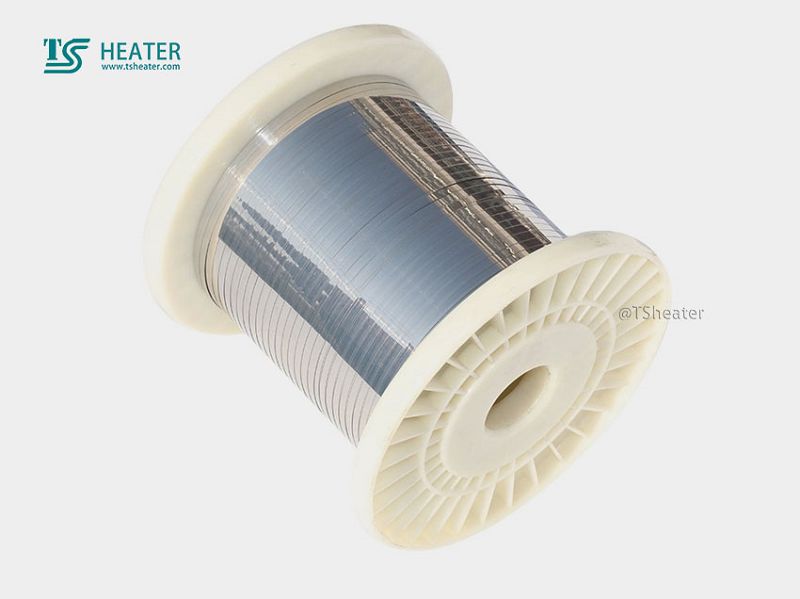

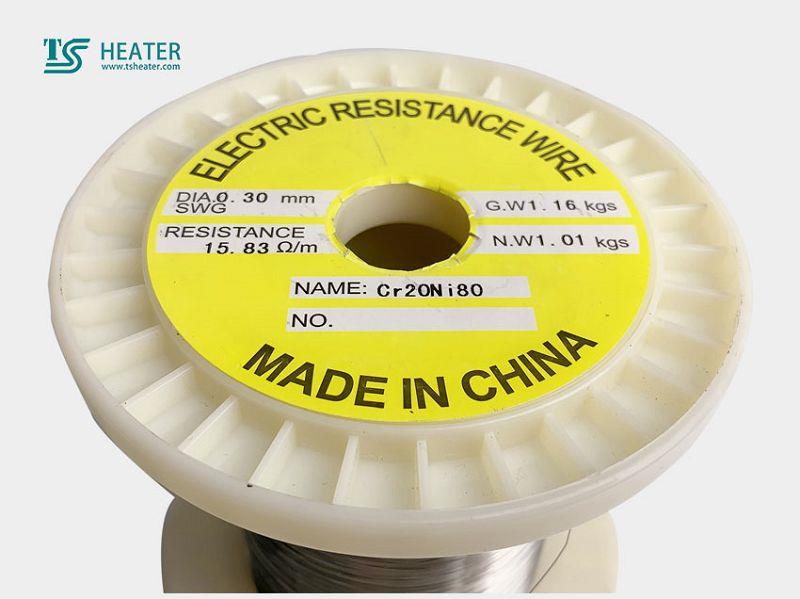

Cr20Ni80 is a resistant electric heating alloy. Stable microstructure and electrical and physical properties, good high-temperature mechanical properties, good cold deformation plasticity, good weldability, and long-term use without brittle fracture. The working temperature of Cr20Ni80 is below 1000℃, and the service life is long.

Adhering to the principle of first-class quality, high efficiency and low price, our company constantly provides customers with various high-quality barrel heater blankets, silicone mat for iron, fiberglass wire sleeve. Over the years, our company has always adhered to the 'technology to improve the quality of products, to expand the image of the enterprise through cooperation' as a core content of corporate culture. We will further play our advantages, improve production efficiency and provide high-quality and efficient services for customers at home and abroad. A high starting point, high quality, and high reputation are our eternal pursuit.

Cr20Ni80 has excellent comprehensive properties. High-quality heating elements will choose Cr20Ni80. Cr20Ni80 has the advantages of good oxygen resistance, high strength, non-magnetic, high emissivity, good corrosion resistance, no softening, no deformation, and low permanent elongation.

Application range of Cr20Ni80:

1. As an advanced heating element, it is mainly used for periodic heat treatment furnaces whose operating temperature is below 1000℃, such as carburizing furnaces, bell furnaces, ammonia decomposition furnaces, etc.

2. It can be widely used in metallurgy, household appliances, machinery manufacturing, and other advanced heating elements and as advanced resistance materials in the electrical industry.

3. Used for resistance bands in high-quality resistance boxes.

4. It can also be used as high-quality heat-resistant steel structural parts, such as high-temperature mesh belts, burning racks, etc.

5. Using Cr20Ni80, it also represents the high-quality symbol of electric heating products

Paraments | Specification |

Type | Cr20Ni80 |

Chemical Composition | Cr:22%,Ni:Rest |

Max continue operating temp. (°C) | 1200 |

Resistivity (10-6 Ω.M) at 20°C | 1.09±0.05% |

Specific heat capacity at 20 °C J/gk | 0.440 |

Density at 20 °C (g/cm3) | 8.4 |

Melting temp °C | 1400 |

Elongation | 25 |

Microstructure | Austenite |

Delivery & Enquiries:

Most items are available for delivery in 3 to 7 working days. However, Ts heater does offer additional emergency services for customers who are in a breakdown situation. This includes 48hr service on Mica products, Cartridge Heaters, and Ceramic Knuckle Heaters. For all inquiries please contact a member of our sales team who will be happy to assist.

Our company not only provides users with advanced technology and high-quality Electrolytic Nickel/Nickel Alloy/Battery Ni/Spring Steel Rod/Nickel, but also pays attention to and captures the needs of customers wholeheartedly. Our products have always maintained the leading domestic level with reliable quality, and are widely trusted by customers. We are determined to work harder to create a better future with our customers. 'Perfect the mechanism, strengthen the management, increase the efficiency' is my company's overall management policy. Our company provides customers with better products and services with a scientific attitude and a responsible spirit. Welcome to visit us.