Water Tank with Immersion Heater : 1 100% guaranteed no leakage welding; 2. Excellent sealing performance; 3. Limited protection against safety accidents caused by heaters.

In terms of dimplex tubular heater 80w, aluminium foil heater, testing hot water heater element industries, our products have been developed according to domestic and foreign markets. We follow a spirit of care about the world, dare to become a pioneer, having been ahead of the technology's leading edge research and development in the industry. Our company fully implements the international quality management system standards, strictly manufactures products with reliable quality and complete specifications, and our products have won the trust of customers. We never slack in the pursuit of the best position in the global market. Therefore, we hope to obtain higher customer satisfaction by improving our quality level and establish a closer relationship with customers.

Advantages of Water Tank with Immersion Heater:

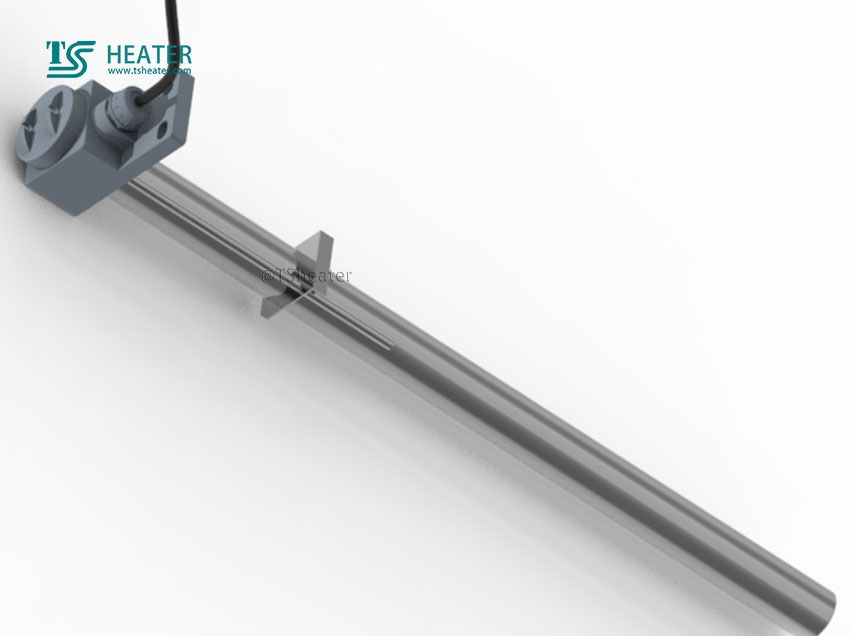

1. Automatic welding is adopted in the mouth, 100% guarantee no leakage welding;

2. Epoxy resin is used for sealing, with excellent sealing performance;

3. Ul94-v0 grade flame retardant wire connection box can effectively prevent safety accidents caused by heater;

4. Make the heater cable according to national standard to ensure that the heater will not cause fire accident due to excessive current;

Notes for use of Water Tank with Immersion Heater:

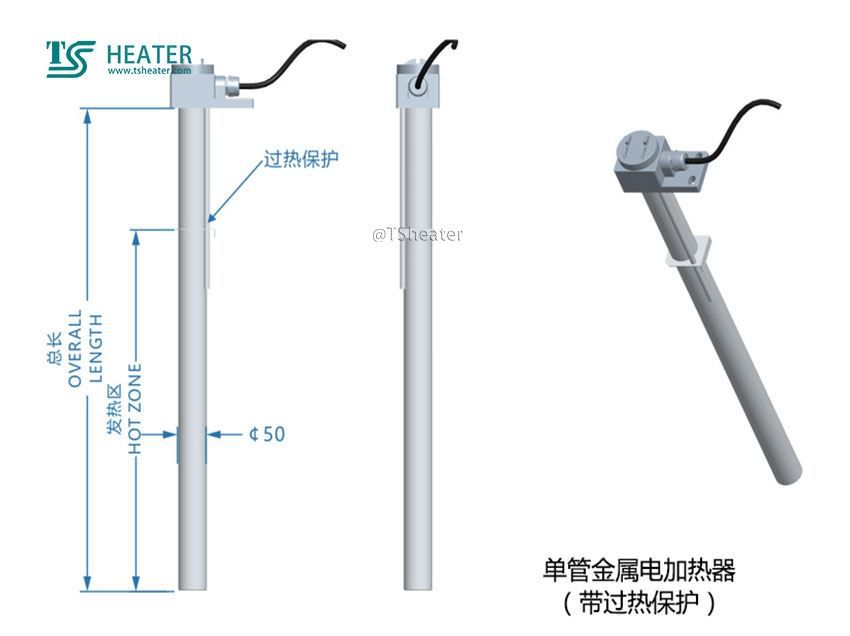

1. Temperature fuse: The temperature fuse device is in the casing tube next to the heater. When the liquid level drops and the temperature exceeds the safe value of the fuse, the fuse will be blown out, playing a protective role. The fuse needs to be replaced after it burns out. The temperature parameter of the fuse is 250V/5A 105℃ or 95℃

2.The Sensor is placed in the casing next to the heater. When the liquid decreases and the temperature exceeds the over-temperature point, the temperature will be turned on and the power will be turned off to protect the heater. When the temperature drops, the power can be switched on again. Temperature starting parameter: 250V/5A 105℃ or 95℃.

3. The reconnecting temperature of the temperature switch is 15℃ lower than the overtemperature point.

4. Due to the limitation of electrified flow, contactors are required for temperature fuses and temperature heads. It is not possible to directly connect the load of power supply and electric heater.

Quality assurance: all metal tube heaters can be guaranteed for one year in the case of non-human damage or wrong design, and can provide long-term maintenance services according to customer requirements.

We are committed to becoming the leader in this industry, insisting on selling Flat Plate Solar Collector Hot Water Heating System at the most competitive prices, providing customers with diversified services, and striving to fully meet customer requirements. We can supply high quality products with the very competitive price. We have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers.