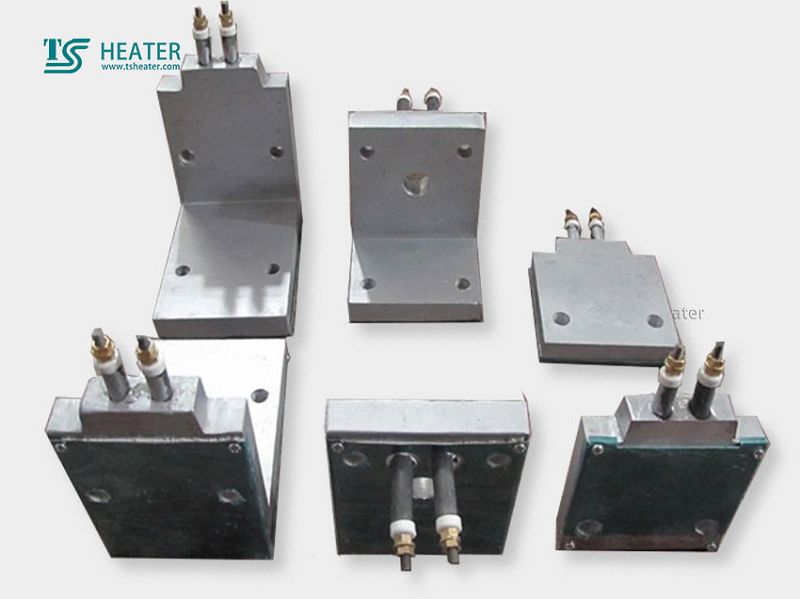

TS heater are leading manufacturer, Importers and Service Provider of Aluminum Cast-In Heaters and our product is made up of good quality.Right Angle Aluminum Casting Electric Heaters

Our products are exported for 3d printer cartridge heater, heating coil abbie's bunker, teflon tape. We are looking for a better production and operation management plan to improve the efficiency of production, operation and management of the enterprise, thereby enhancing the core competitive advantage. We wish to just take this opportunity to ascertain long-term enterprise relationships with clients from all over the earth. 'Serve attentively and pursue quality', this company has always insisted on starting from the foundation of enterprise development, adopting mature humanized management within the company.

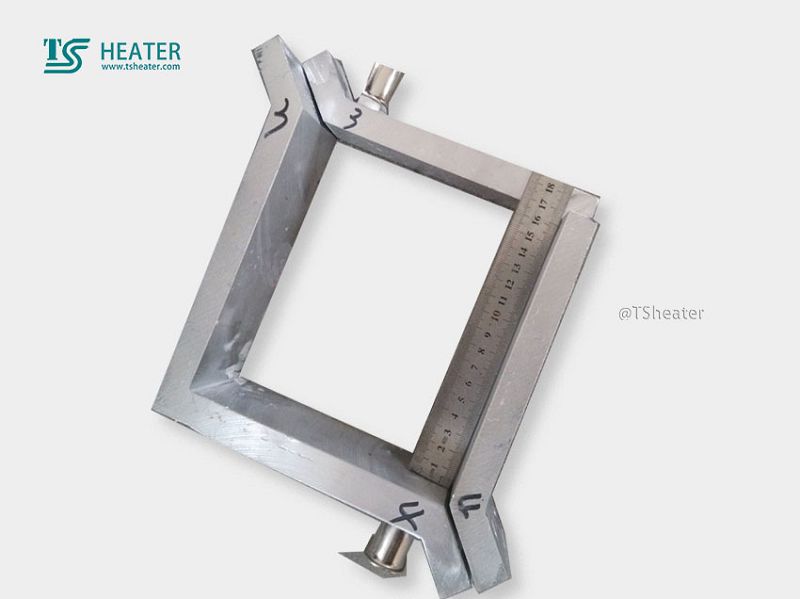

TS heater are leading manufacturer, Importers and Service Provider of Aluminum Cast-In Heaters and our product is made up of good quality.Right Angle Aluminum Casting Electric Heaters

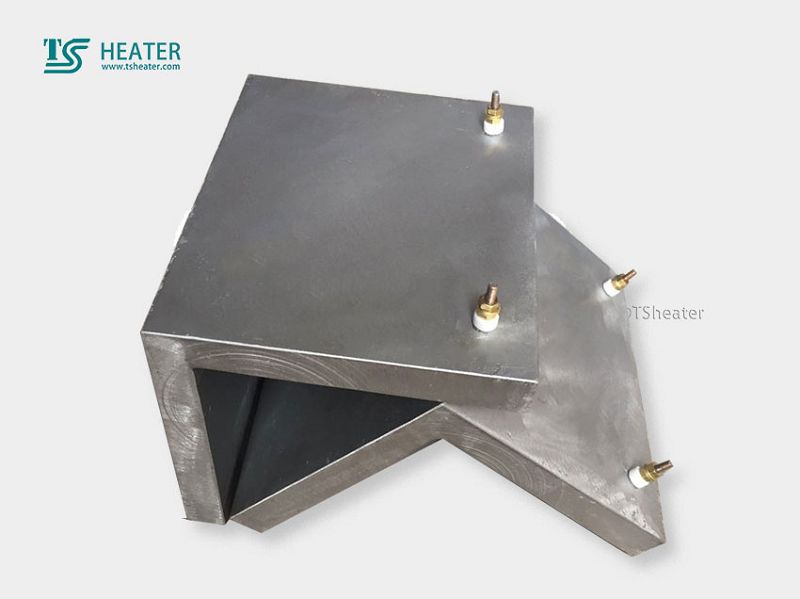

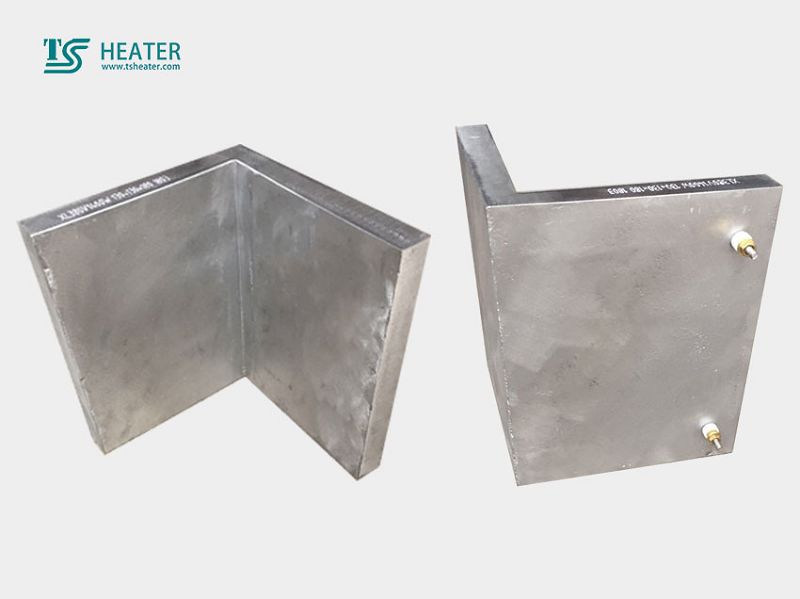

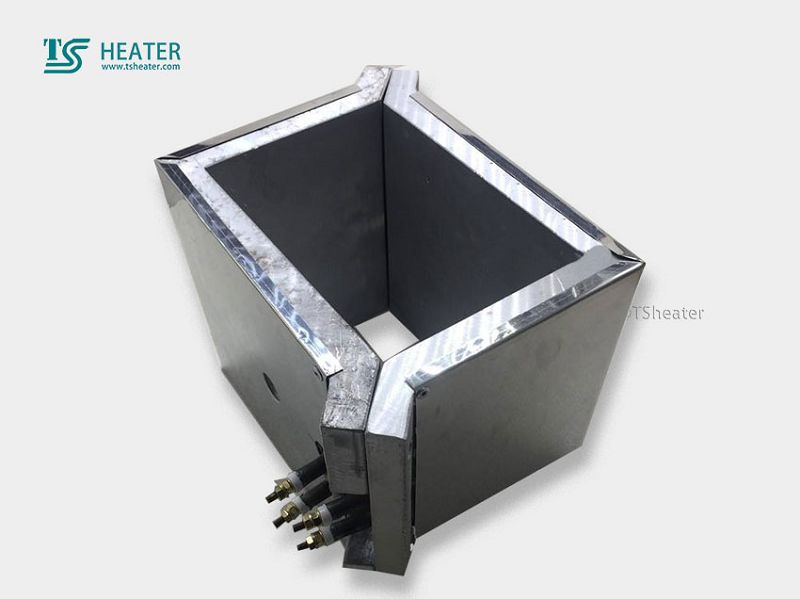

These heaters are made up of high quality aluminium and are extensively acclaimed for high heating effect and high functionality.

These are manufactured by our experts using high-grade raw material in accordance with the quality standards.

Features:

Right Angle Aluminum Casting Electric Heaters

· Efficient Heat Transfer.

· Cast-in heaters can be supplied with cooling tubes & end fitting.

· Various Heater terminations.

· Uniform surface temperatures.

· Also as per your requirements.

· Max watt density: Aluminum alloy - 35 w/sq in on heater elements.

· Brass alloy - 45 w/sq in on heater elements.

· Max temp: Aluminum alloy - 375 °C, Brass alloy - 650 °C

Applications:

Right Angle Aluminum Casting Electric Heaters

· Injection and Blow Molding

· Extruders

· Molds & Dies

· Packaging machinery

· Medical equipment

· Thermoforming equipment.

Package:

What are the precautions for ordering cast aluminum heater?

1.The user should provide product drawings or samples. If there are no drawings or samples, the specifications, model, voltage, power, etc. of the product must be provided.

2.The surface electric power of the cast aluminum electric heater is between 2.5 and 4.0 watts per square centimeter.

The Foundry Metal Zamak ADC12 Zinc Alloy/Aluminium/Aluminum/Aluminum Alloy/Aluminium Alloy Sand-Gravity-Die Casting for Machining Hardware Part we produce have the advantages of long service life, reasonable structure, beautiful appearance, novel styles, and first-class quality, which is a new generation of products with strong vitality. With the evolution of technology and the improvement of management, we will give back the results to business partners to create a win-win situation. We have established a mechanism to develop, train and reserve talents from within the enterprise, thus effectively avoiding the risks caused by personnel turnover.