Ocr25Al5 Wire Widely used in industrial furnace, household appliances, metallurgy, machinery, aircraft, automobile, military and other industries to produce heating elements and resistance components. Ocr25Al5 Wire

Today, the oven heating element resistance, type k terminal block, heating aluminum cast has been recognized and accepted all over the world and is loved by our customers. We persist with the principle of 'quality 1st, assistance initially, continual improvement and innovation to meet the customers' for your management and 'zero defect, zero complaints' as the standard objective. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

0Cr25Al5 resistance electric heating wire

Fekelar alloy has the characteristics of high resistivity, low resistivity, high working temperature, high temperature oxidation resistance and corrosion resistance.

Widely used in industrial furnace, household appliances, metallurgy, machinery, aircraft, automobile, military and other industries to produce heating elements and resistance components.

Resistance wire 0Cr25Al5 / OCr25Al5 ferrochrome alloy

Resistance heating wire is a common material of ferrochrome aluminum alloy.

Fekelar alloy has the characteristics of high resistivity, low resistivity, high working temperature, high temperature oxidation resistance and corrosion resistance.

Widely used in industrial furnace, household appliances, industrial furnace, metallurgy, machinery, aircraft, automobile, military industry and other industries to produce heating elements and resistance components.

Size range:

Ocr25Al5 Wire

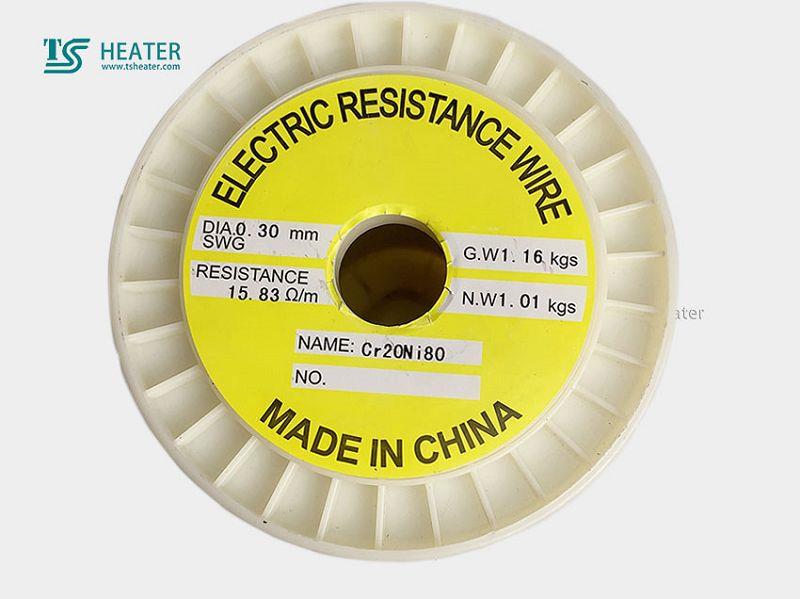

Thread: 0.01 -10 mm

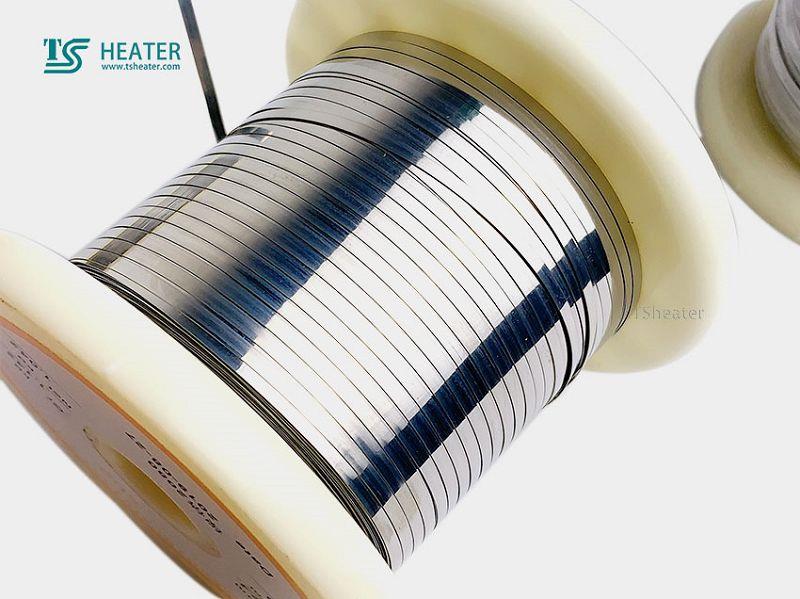

Ribbon: 0.05 * 0.2-2.0 * 6.0 mm

Band: 0.05 * 5.0 -- 5.0 * 250 mm

Bar: 10 to 50 mm

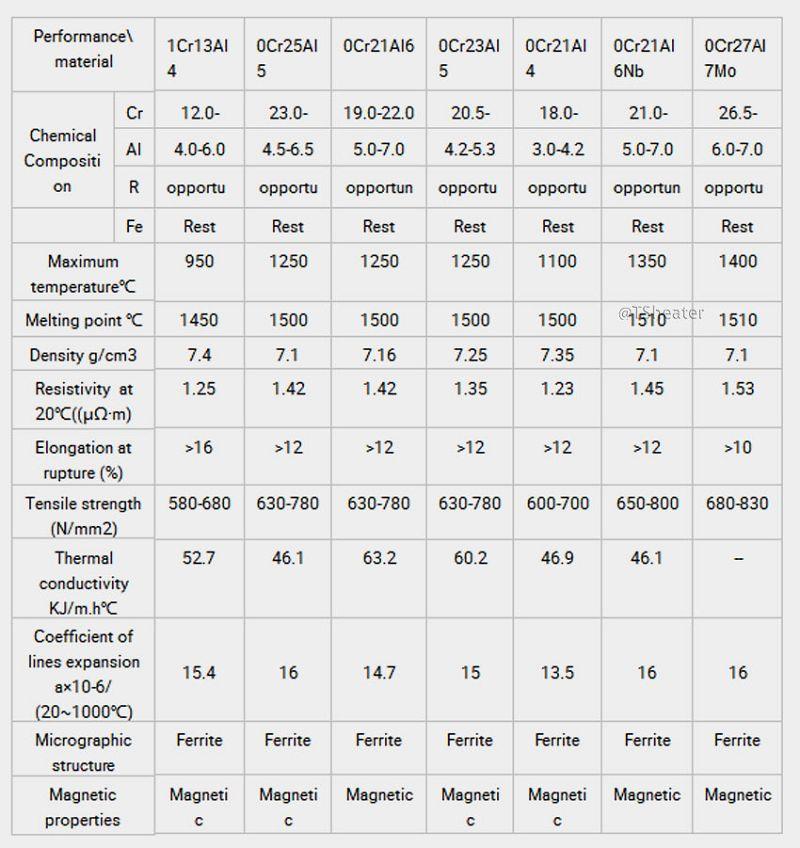

FeCrAl alloy series: OCr15Al5, 1Cr13Al4, 0Cr21Al4, 0Cr21Al6, 0Cr23Al5, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2, etc.

Details

Ocr25Al5 Wire

Place of Origin:GuangZhou, China

Brand Name:TS W

Model Number:0Cr25Al5

Type:Bare

Application:Heating

Conductor Material:Copper Clad Aluminum

Conductor Type:Solid

Surface:Bright

Resistivity:1.42

Maximum Temperature:1250℃

Melting Point:1500℃

Technique:Cold Drawing

Treatment:Hydrogen Annealing

Condition:Soft Annealed

Certificate:ISO9001, SGS

Delivery Time:7-20 Days

Tensile Strength:630-780

Ocr25Al5 Wire

Delivery & Enquiries:

Most items are available for delivery in 3 to 7 working days. However, Ts heater do offer additional emergency services for customers who are in a breakdown situation. This includes a 48hr services on Mica products, Cartridge Heaters and Ceramic Knuckle Heaters. For all enquires please contact a member of our sales team who will be happy to assist.

Our company advocates the business philosophy of 'honesty, pragmatism, and quality', and is committed to professional design, production, and sales of all kinds of GY FeCrAl 0Cr25Al5 resistance wire for tubular heater, providing customers with efficient service and high-quality products. Customer satisfaction is our service guidelines. We always develop and design kinds of novel products to meet the market demand and help the guests continuously by updating our products. We will endlessly make efforts to supply creative and qualitative products for local as well as global customers based on honest mind for partners which is the great motto of us.