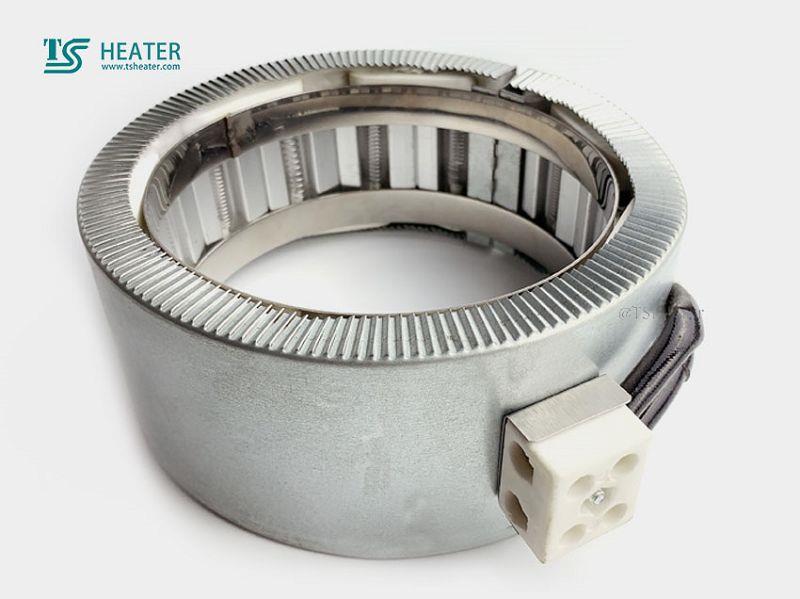

IR energy saving band heater is professional energy-saving device , aim to assist plastic machine increasing the heat efficiency. Utilizing the high resistance heating wire to generate heat and through the infrared radiation way to conduct thermal effect for plastic processing machine.IR Energy Saving Band Heater

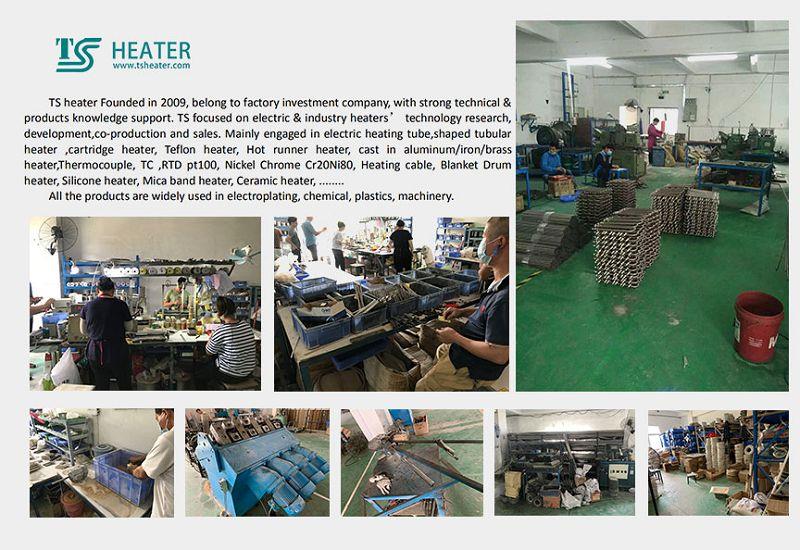

We pay attention to product development and quality, so that our compressed air heaters tubular, dc solid state relay, air finned heater reaches the leading level of similar products. Our aim is 'blazing new ground, Passing Value', in the future, we sincerely invite you to grow up with us and make a bright future together! Our company has set up a high-quality maintenance service center, our all-round service enables you to have a good product at the same time also has a more assured service. Hope to get inquiries type you and construct a long-term co-operation partnership. We always adhere to the market-oriented, committed to the progress of science and technology and quality improvement, and have advanced production equipment with strong technical force, products are widely used in various fields.

IR Energy Saving Band Heater IR energy saving band heater is professional energy-saving device , aim to assist plastic machine increasing the heat efficiency. Utilizing the high resistance heating wire to generate heat and through the infrared radiation way to conduct thermal effect for plastic processing machine.

It adopts import electric wire as heating conduction, at maximum extent increase the heat transfer efficiency between heating element and barrel. Electric heat transfer efficiency rate up to 99.8%. The inner use the aerospace grade material air-gel as the insulation material. The surface temperature is under 35℃, which improve the shortcomings for traditional band heater, such as low conversion efficiency of electric heat, low heat transfer efficiency, high temperature in surface etc, thereby the Nano infrared band heater could achieve to saving energy.

Plastic machine nano infrared heater generates high heat by high-resistance wires which is reflected by quartz halogen heating tubes. It has high thermal efficiency, excellent energy-saving effect and quite low heater surface temperature. Following induction heating, it is another high energy-saving heating technology which is now widely used in plastic machines.IR Energy Saving Band Heater

Application range: IR Energy Saving Band Heater

injection molding machine, granulator, extruder, drawing machine, blown film machine and other plastic machinery and other system need to use electric heat.

Features: IR Energy Saving Band Heater

1. 4ultras:ultra-high energy-saving,ultra-low surface temperature,ultra-fast heating rate,ultra long service life

2. Electric heat transfer efficiency up to 99.8%,energy saving rate up to 30% -83%

3. Infrared radiation heating mode, high efficiency, unidirectional radiation

4. The surface temperature is under 35 degrees, greatly improve the operating environment

5. Easy to install and replace,simple and stable structure, the service life of up to 50,000 hours;

Details:

Order guide:

When order IR energy saving band heater ,please kindly inform us the information as following:

1.The inner diameter (mm) (or outer diameter when the heater is used inside) and length (mm) of heaters

2.Width of heaters

3.Voltage and power density

4.Position and size of the hole for thermocouple

5.Wiring type and position

6.Content of the stamping if needed

7.Special gap if Necessary

8.Order quantity

9.Delivery date

We have always insisted the quality strategy,' Not the largest, but the best', and try our best to build a modern enterprise with 'unique and quality' High Frequency Metal Forging Heat Treating Induction Heater Manufacturers. After years of business, our company has achieved leapfrog development. Our products are completed by our own team from R&D to production, which can fully control all links in the product production cycle to ensure that the products are delivered on time and quality.