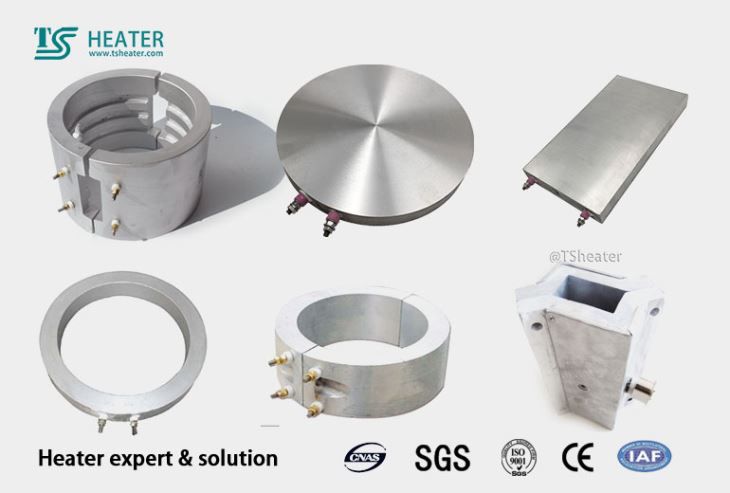

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round,Aluminum Casting Heater

Our company adheres to the business philosophy of 'integrity, win-win, quality and service', constantly innovating technology, enriching product lines, and continuing to provide customers with superior quality and durable hot tub heater element resistance, refrigerator defrosting, hotwatt cartridge heaters. We concerned about the introduction of foreign investors and strategic partners as a major impetus to development of our company. We continue to deepen product research, simplify operation procedures to provide high-quality products to users. In the process of customer use, we provide customers with convenient and effective solutions, and our sales network is all over the world. We treat each customer in accordance with the industry integrity, do not falsely quote product prices.

Aluminum Casting Heater

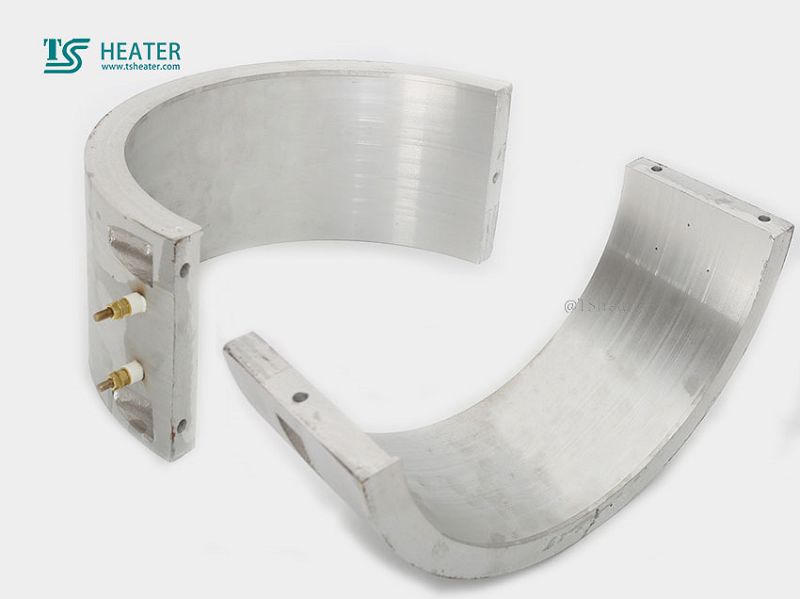

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round, flat, rectangular, air-cooled, water-cooled and other special-shaped etc..

Aluminum Casting Heater

After finishing it and heated body tightly, Metal casting heater is a kind of high efficiency heat uniformity division of the heater, thermal conductivity, excellent metal alloy, ensure the hot surface temperature uniformity, eliminating equipment hot and cold spots. With long life, good insulation properties, mechanical properties, corrosion resistance, magnetic resistance etc..

Aluminum Casting Heater

The outer radiating surface increases thermal insulation device, within the radiating surface of sintering infrared which can save 35% of electricity

Feature:

Aluminum Casting Heater

1.Cast aluminum surface load can reach 2.5-4.5w / cm2, maximum operating temperature 400-500 °C;

2.Cast copper surface load can reach 3.5-5.0w / cm2, maximum operating temperature 600-700 °C;

3.Cast iron surface load can reach 4.5-6.0w / cm2, maximum operating temperature 800-850 °C.

Customers’s cast in heater,ready to send out:

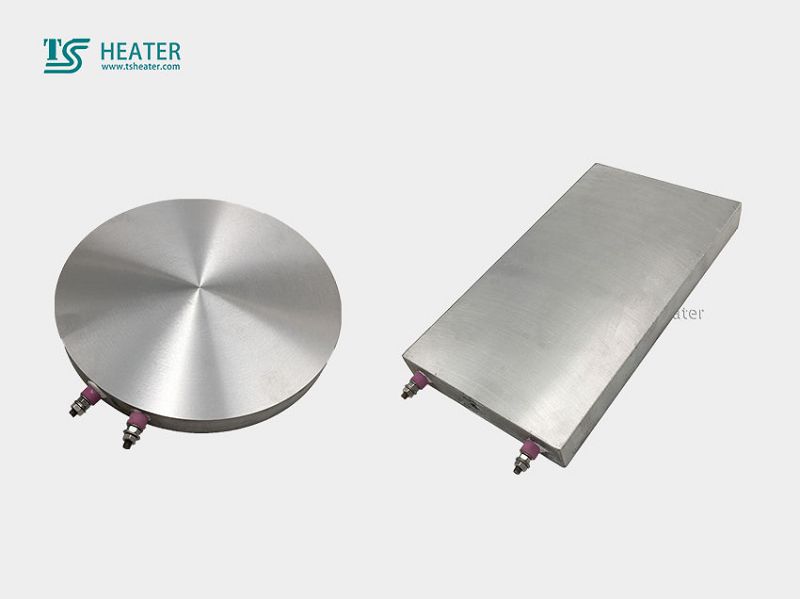

Our clients can avail a variety of Cast Aluminium Plate Heater from us. These plate heaters are designed by engineering experts working with us to suit requirements of different types of industries and client. These heaters are constructed using high-class aluminium which is procured from reliable vendors. Our heaters are highly praised for its complex designs and durability. We also offer customized solutions of these heaters understanding requirements and specifications of clients.

Our company adheres to 'integrity and quality as the foundation' policy, and establishes a good long-term cooperative relationship with customers at home and abroad, and strives to build itself into a High Pressure Aluminum Alloy Die Casting for Radiator Shell manufacturer that new and old customers can trust for life. 'Good quality, Good service ' is always our tenet and credo. We always take innovation and technology as the development direction, return to the new and old customers, and maximize the interests of customers.