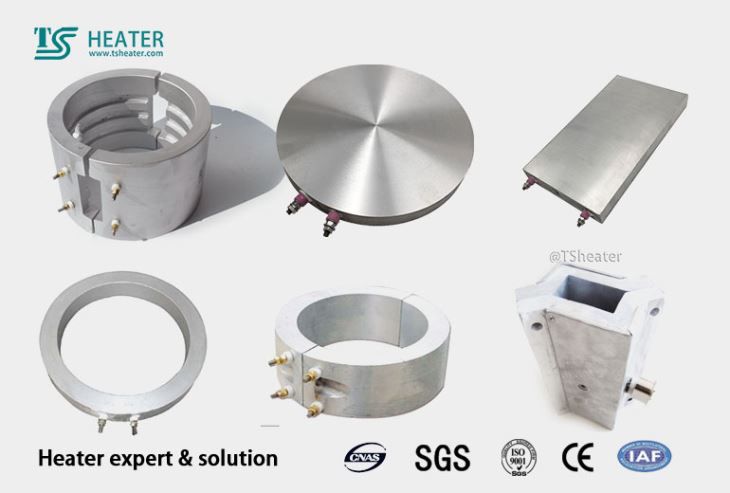

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round,Aluminum Casting Heater

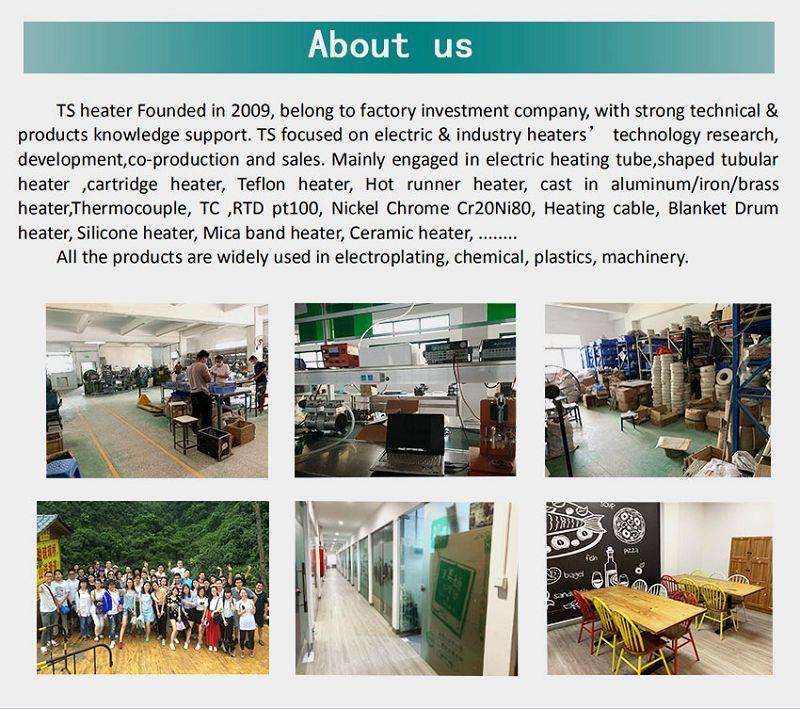

Our company strives to provide the best overall solution and the best quality service for enterprises in the market environment of labor shortage and quickly improve the quality and production efficiency of heat resistant mat kitchen, coil heater for hot tub, tubular heaters with thermostat. In terms of talent introduction, our company does not hesitate to invite foundry technical experts to check in person, so that the comprehensive competitiveness of the team has been improved. Our company will continue to increase investment in product research and development, and continue to optimize the product structure. We hope to help customers get the best experience with products that are most suitable for everyone, while solving various social problems.

Aluminum Casting Heater

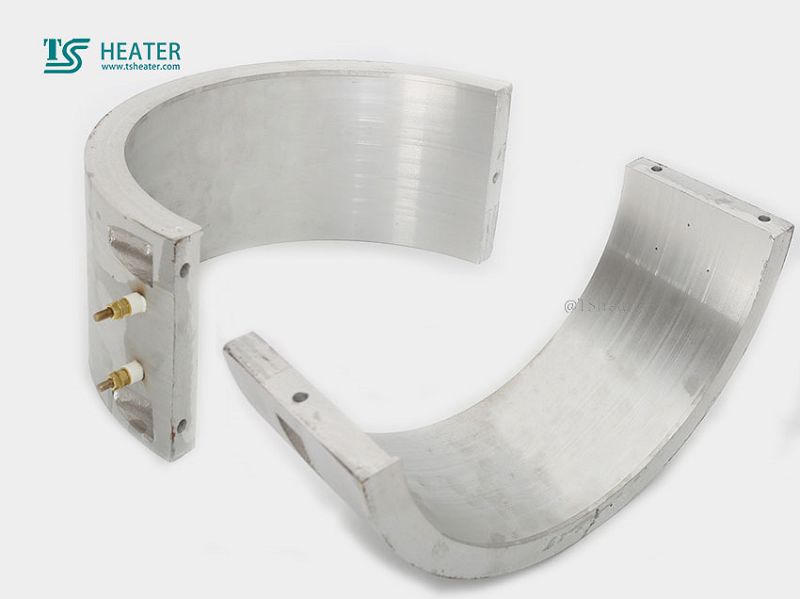

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round, flat, rectangular, air-cooled, water-cooled and other special-shaped etc..

Aluminum Casting Heater

After finishing it and heated body tightly, Metal casting heater is a kind of high efficiency heat uniformity division of the heater, thermal conductivity, excellent metal alloy, ensure the hot surface temperature uniformity, eliminating equipment hot and cold spots. With long life, good insulation properties, mechanical properties, corrosion resistance, magnetic resistance etc..

Aluminum Casting Heater

The outer radiating surface increases thermal insulation device, within the radiating surface of sintering infrared which can save 35% of electricity

Feature:

Aluminum Casting Heater

1.Cast aluminum surface load can reach 2.5-4.5w / cm2, maximum operating temperature 400-500 °C;

2.Cast copper surface load can reach 3.5-5.0w / cm2, maximum operating temperature 600-700 °C;

3.Cast iron surface load can reach 4.5-6.0w / cm2, maximum operating temperature 800-850 °C.

Customers’s cast in heater,ready to send out:

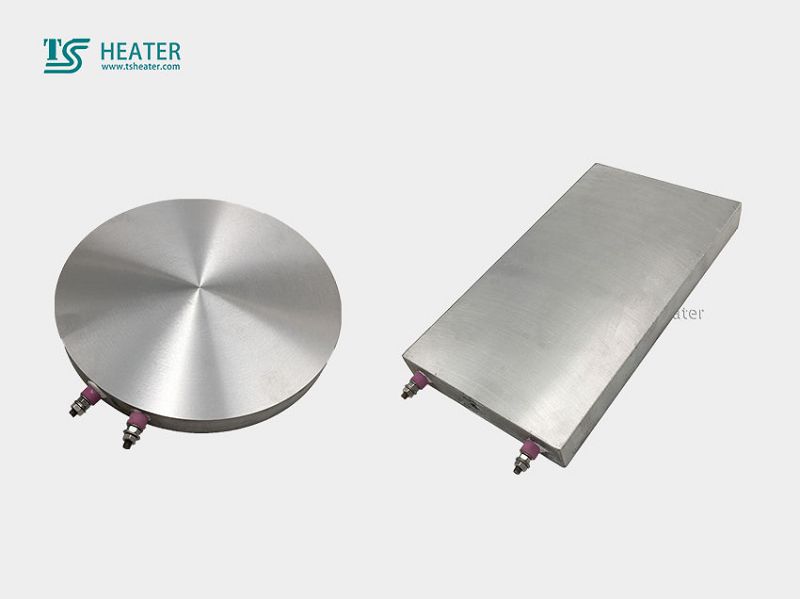

Our clients can avail a variety of Cast Aluminium Plate Heater from us. These plate heaters are designed by engineering experts working with us to suit requirements of different types of industries and client. These heaters are constructed using high-class aluminium which is procured from reliable vendors. Our heaters are highly praised for its complex designs and durability. We also offer customized solutions of these heaters understanding requirements and specifications of clients.

We have won the reliance and support of the majority of users by relying on a complete after-sales network and superior and inexpensive High-Strength Prefabricated Steel Frame Building. In order to allow our customers buy comfortably and use them at ease, our production staff have gone through countless experiments and tests to get the final perfect product. Before export of the product there is strict top quality control check during treatment as per international good quality standards.