Water Tank with Immersion Heater : 1 100% guaranteed no leakage welding; 2. Excellent sealing performance; 3. Limited protection against safety accidents caused by heaters.

We constantly carry out our spirit of ''Innovation bringing advancement, Highly-quality guaranteeing subsistence, Administration selling advantage, Credit rating attracting buyers for Manufacturer for mica insulation sheet, water immersion rod, aluminium pressure die casting. Our business philosophy is to improve ourselves, create benefits for enterprises and provide customers with truly valuable products and services. Through constant upgrading and improvement in practice, our products have finally won the affirmation of the market and have sprung up in the industry. We advocate designers to go into life, into the market, to see, think and feel with their own heart and eyes, and this is fed back into the product and back to life. We give full play to the important role of science and technology as the first productive force and attach great importance to scientific and technological progress and innovation.

Advantages of Water Tank with Immersion Heater:

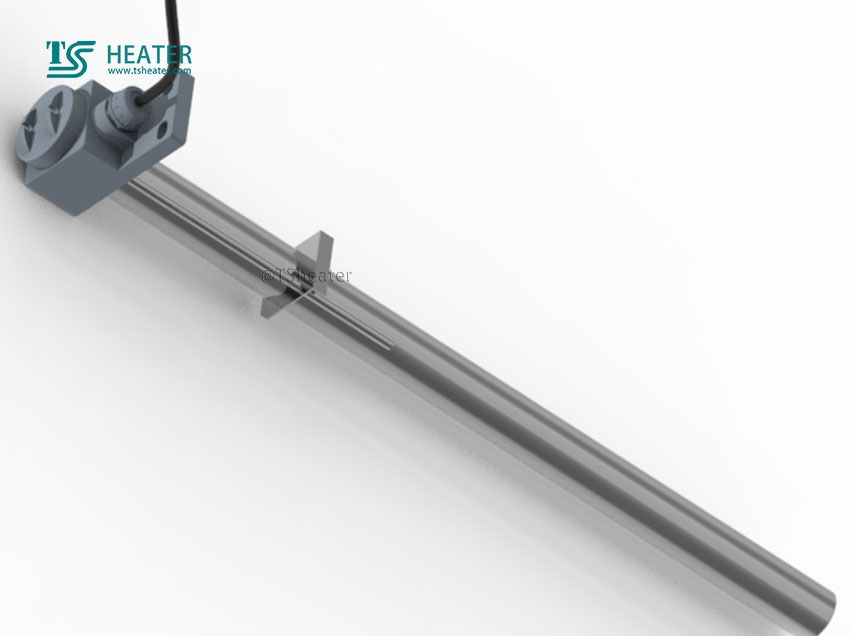

1. Automatic welding is adopted in the mouth, 100% guarantee no leakage welding;

2. Epoxy resin is used for sealing, with excellent sealing performance;

3. Ul94-v0 grade flame retardant wire connection box can effectively prevent safety accidents caused by heater;

4. Make the heater cable according to national standard to ensure that the heater will not cause fire accident due to excessive current;

Notes for use of Water Tank with Immersion Heater:

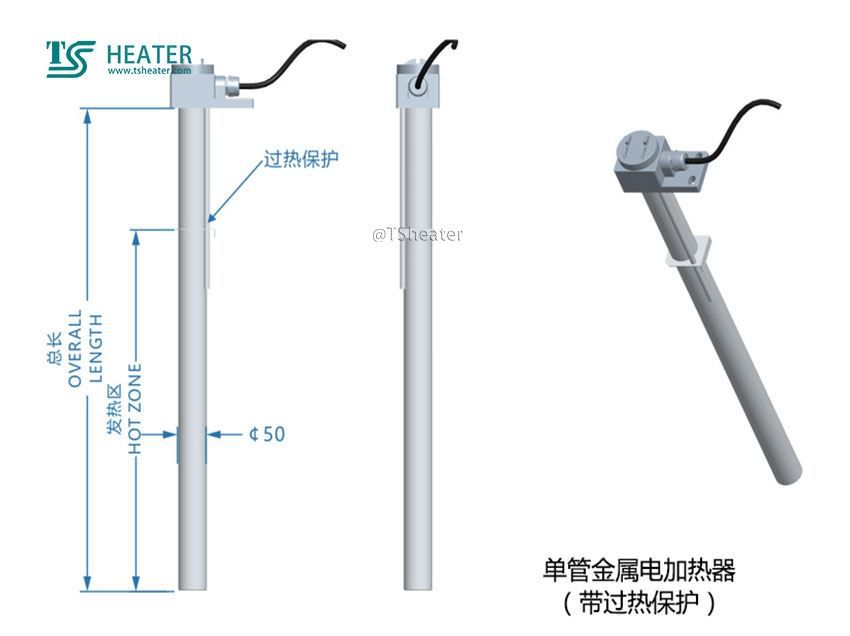

1. Temperature fuse: The temperature fuse device is in the casing tube next to the heater. When the liquid level drops and the temperature exceeds the safe value of the fuse, the fuse will be blown out, playing a protective role. The fuse needs to be replaced after it burns out. The temperature parameter of the fuse is 250V/5A 105℃ or 95℃

2.The Sensor is placed in the casing next to the heater. When the liquid decreases and the temperature exceeds the over-temperature point, the temperature will be turned on and the power will be turned off to protect the heater. When the temperature drops, the power can be switched on again. Temperature starting parameter: 250V/5A 105℃ or 95℃.

3. The reconnecting temperature of the temperature switch is 15℃ lower than the overtemperature point.

4. Due to the limitation of electrified flow, contactors are required for temperature fuses and temperature heads. It is not possible to directly connect the load of power supply and electric heater.

Quality assurance: all metal tube heaters can be guaranteed for one year in the case of non-human damage or wrong design, and can provide long-term maintenance services according to customer requirements.

Our factory has always adhered to the corporate tenet of honesty, quality as the root, perfect service, and strict management, and has won the support and trust of people in the industry of Industrial Heating Element Manufacturer, Heating Element Factory. We have a high reputation in the industry with superb technology, strict manufacturing technology and sound production management system. Since our company was founded for many years, with the care for and help of friends, we have rapidly developed and have gotten stronger in the industry.