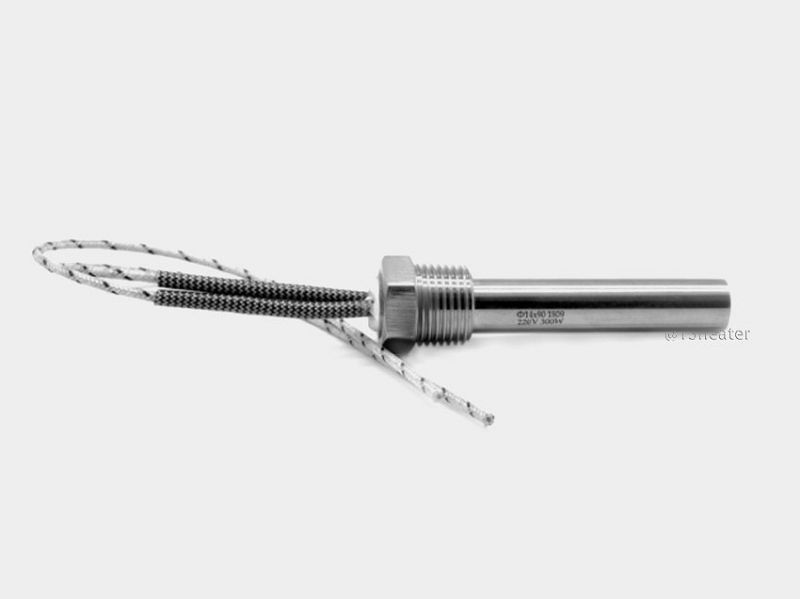

As a very widely used heater,Heater Cartridge Construction permits higher watt densities. Standard SS316 and optional Incoloy 800 sheath provide good thermal conductivity and resistance to corrosion and scaling.Heater Cartridge

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for band heater with thermocouple, coil bolt heater, thermocouple crimp connectors. We attach great importance to team building, staff quality education and skill training with the guiding ideology of 'being a man in advance'. We widely apply new technologies, new processes, new equipment and new materials to develop marketable products.

As a very widely used heater,Heater Cartridge Construction permits higher watt densities. Standard SS316 and optional Incoloy 800 sheath provide good thermal conductivity and resistance to corrosion and scaling. Heater Cartridge

Features: Heater Cartridge

● Max Sheath Temperature 800°C (Depend of sheath material)

● 6V ~ 480V Voltages

● Dia.3mm to 30mm

● High Purity MGO

● Glass filament blanket

● 12” standard lead wire length

● Crimped On Lead & Swaged In Lead

● Custom design or built in thermocouples are available

Application:

● Semiconductor chamber heating

● Semiconductor wire & die bonding

● Humidity Control

● Patient comfort heating used in medical devices

● Mold die and platen heating

● Seal bars used in packaging equipment

● Test sample heating in gas chromatography equipment

Each Heater cartridge is carefully designed

Construction of a cartridge heater may be divided in 6 main parts:

1.Heating coil

The heating coil is the actual resistance which is where the electrical load occurs. The most common type of metal alloy used for this purpose is a nickel-chromium mixture, also known as nichrome. The nichrome wire is wound around a ceramic core, and the number of spirals per inch vary according to the requested watt density. Potential from an alternating current source, which can either be 2 phase or 3 phase, flows through the coiled nichrome wire, heating up the wire, which in turn, heats the cartridge heater sheath.

2.Insulation

Insulation is used to prevent the nichrome coil contacting the sheath, an event that would ground the resistance and could produce a catastrophic short-circuit, resulting in a melted sheath and a major equipment failure. Damage can be mitigated by installing a ground fault interrupting circuit. To prevent the coil from touching the sheath, the coil is inserted into the sheath, and immediately filled with magnesium oxide (MgO). To ensure the MgO fills the empty space between the sheath and the coil, the cartridge heater is filled under vibration.

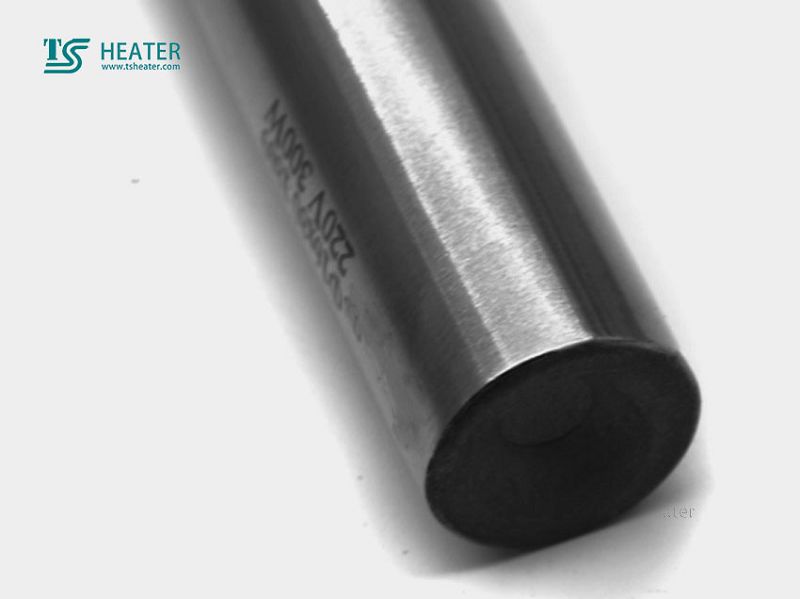

3.Sheath

The sheath is the part of the cartridge heater which makes contact with the material or substance to be heated. Several metal alloys are used, depending on the type of application, such as highly acidic or corrosive environments. The most common types of sheaths are 304 stainless steel, 316 stainless steel, and incoloy 800. Incoloy has the highest temperature rating, and is considered a superalloy.

4.Sealing

After the cartridge heater has been filled with MgO, a seal is applied to the open end of the cartridge heater (where the nichrome coil was introduced). This prevents the coil and the MgO from coming out, as well as preventing contaminants such as plastic debris, air, or moisture from entering the heater.

5.Termination

Since cartridge heaters are installed in a wide variety of machines, manufacturers must design the heaters to meet certain clearances.[7] [dead link] The cartridge heaters might be terminated with the leads coming out straight, or in a right angle. Also, manufacturers must be careful that the leads are not exposed to temperatures higher than the maximum rating for the lead wire. In order to prevent lead wire damage from temperature, movement or contamination, the lead wire can be protected with a metal conduit, braided metal or silicone sleeves.

6.Lead wire type

Depending on the clearance and the design of the machine where the cartridge heater will be inserted, the type of wire used will vary. Fiberglass is the commonly used for cartridge heaters and other high-temperature applications, such as automotive wiring harnesses and industrial equipment. Other variants used are silicone impregnated fiberglass and silicone rubber.

We have formed a good reputation and been widely recognized by the majority of users by reassuring Industrial Metric Insertion Cartridge Heaters Heating Elements, satisfying price and inspiring service. Our company has made a further qualitative leap, and we implement the product structure adjustment to enhance the comprehensive strength of our company. Our company always takes the market as the guidance, each product update records the innovation spirit that we strive for to meet the changing market demand.