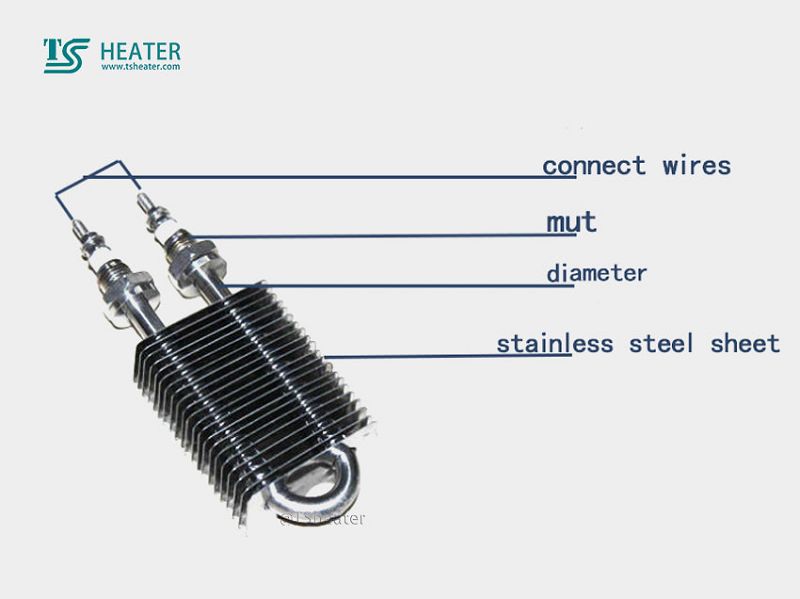

It’s a versatile and economical heat source for a wide variety of industrial and commercial applications.Standard tube diameters are 6mm, 8mm, 10mm, 12mm, 16mm,18mm,20mm etc ,other special sizes are available for Finned strip heater.Finned Strip Heater

We have outstanding product design and production capabilities in the field of Cartridge Heating Elements, plastic strip heater, coil heater for hot tub. With the support of our highly experienced professionals, we manufacture and supply best quality products. As a leading supplier, we offer a wide variety of advanced and mature products and also provide the best services to our clients with the highest level of trust and reliability.

Finned Strip Heater

It’s a versatile and economical heat source for a wide variety of industrial and commercial applications.Standard tube diameters are 6mm, 8mm, 10mm, 12mm, 16mm,18mm,20mm etc ,other special sizes are available for Finned strip heater. Depending on the diameter, lengths can be supplied up to 6000mm. Finned Strip Heater

Standard sheath materials are Stainless Steel 304,310s 316 and 321, but special sheath materials may be available based on diameter and size of the element required.Finned Strip Heater

Specification:Finned Strip Heater

No | Specification parameter | Details |

1 | Product name | Heat Exchange Parts Fin Tube Air Heater |

2 | Material | Stainless steel304,316,Incoloy800,840 |

3 | Voltage | 50V -480V |

4 | Power | 100-10Kw |

5 | Diameter | 10mm- 30mm |

6 | Bush | Brass or stainless steel |

7 | Density | 7-25w /cm² |

8 | Resistance wire | 7-25w/cm2 |

9 | Leak current | Cr20Ni80 or Ocr25Al5 |

10 | Insulation resistance | ≤0.5mA |

11 | Wattage tolerance | ≥11GΩ(cold condition) |

12 | Resistance Power | Cold condition:+5%-10% |

13 | Shape | M shape,U shape,Straight shape |

14 | Warranty | 5years |

Common heaters:

Application: Finned Strip Heater

Semiconductor Chamber Heating ,Water Lead Connection,Wire and Die Bonding

Equipment in Cold Climates or Applications

Medical Devices Equipments

Mold Die and Platen Heating

Packaging Equipment

Test Sample Heating in Gas Chromatography

Heat Transfer Machine etc

We independently research and develop on the basis of introducing and digesting foreign advanced technology, constantly innovate and forge ahead, and strive to create a domestic first-class Jumbo Roll Metallized Film Slitting Rewinding Machine brand. We keep the path of green development and promote the company's product transformation and upgrading. Our development is based on modernization, technology, intelligence, and innovative marketing services.