The machined path in the brass for the heater enables exact repeatability of heat profile. By never exposing the coil heater to molten brass there are no risks of shifted heater coils, or destruction of the thermocouple junction.Brass Coil Heater

We will make just about every exertion for mica heater, thread seal, heater cartridge with thermocouple. Welcome to contact us. In the practical application of products, our company has rich practical experience and scientific and technological strength, which can help customers quickly select suitable products. Various business resources such as product development, technical capabilities, human resources training, global system, flexible response capabilities, and collaboration with business partners, represented by an independent product manufacturing system, support our company's value creation. Good quality would be the key factor to the company to stand out from other competitors.

Advantages of the Brass Coil Heater

1) The inlaid heating wire has a large contact area, and the hot nozzle is clamped by the tension of the copper sleeve itself. There is no gap, the fit is tight, and the appearance is neat and beautiful.

2) Use environmentally-friendly copper materials to reduce environmental pollution;

3) Energy-saving and electricity saving, saving cost.

4) Insulation is above 500 megohms, resistance is +/-1

Materials of the Brass Coil Heater:

1) High-quality resistance wire,

2) High-density magnesium oxide tube,

3) High-temperature resistant wire,

4) All high-quality raw materials are used,

Selection of heating wire:

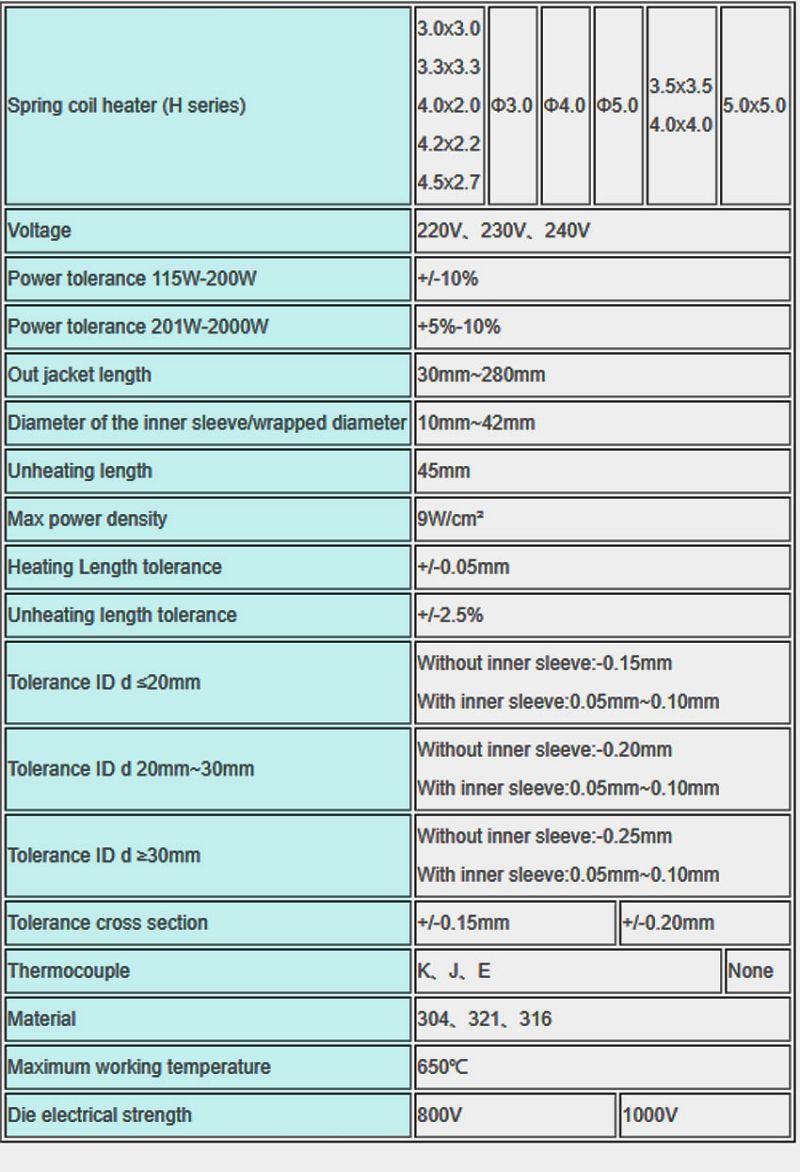

| Round heating wire | diameter | 1.6mm | 1.8mm | 2.0mm | 2.2mm |

| Square flat heating wire | size | 2.2*4.2 | 3.0*3.0 | 3.5*3.5 |

(The specifications of the heating wire are used to select the thickness of the copper sleeve wall to save the space for opening the small mold.)

Application areas of the Brass Coil Heater:

1) Hot runner system

2) Injection mold,

3) Electronics industry,

4) Mechanical equipment,

5) Injection molding machine,

6) Medical machinery,

7) University laboratory

Personal customization of the Brass Coil Heater

1) Our company has a complete production line that can complete a variety of customized products.

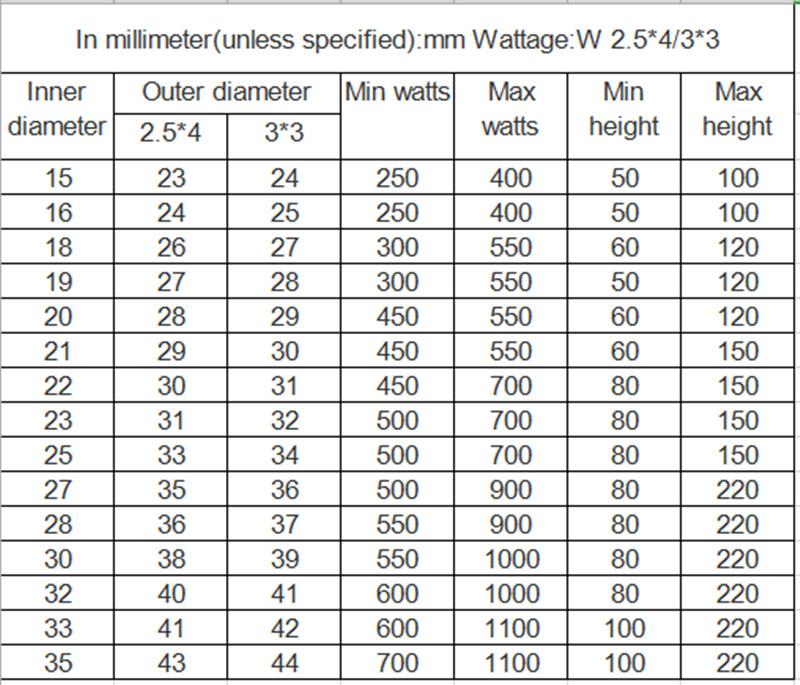

2) Size specifications are customized according to customer requirements.

3) Customize power and voltage.

3) Arrange heating wires.

4) The inner diameter, length, and quantity of the copper sleeve.

5) Whether with thermocouple and model.

6) Lead length (standard 1 meter).

7) Punching temperature materials (especially ABS materials, PA66+30GF%, and other temperature-sensitive materials, please be sure to specify, in order to better and rationally design the arrangement of heating wires).

Packaging & Shipping

- Packing: Carton box

- Delivery Lead Time: 3-5 working days

- Minimum Order: 1PCS

- Supply Ability: 300 per month

- Delivery Port Shanghai,Guangzhou etc.

We vigorously expand the domestic and foreign markets, strive to climb the peak of the Low Price Induction Metal Brass Horizontal Hot Forging Press industry, and develop towards modularization, groupization and internationalization. Our company keeps track of the international development and continuously develops new products with international advanced level. Our company deeply understands the broad connotation of 'ideas determine the way out, details determine success or failure', earnestly pursues the concept of 'quality is the life of an enterprise, and quality is the foundation of the brand', and will continue to make unremitting efforts for the development of the industry.