Submersible Oil Heater,The surface power of the heating tube is 5.6w/cm2, which is suitable for liquid heating with good fluidity, less solid deposition and no crystallization of the liquid on the surface of the electric heater after cooling.

Through continuous improvement of technical support and quality control capabilities, we are able to provide customers with a full range of more valuable and competitive ceramic infrared heater elements, high temp cable, tubular heater. You will instantly feel our professional and attentive service. We have been serving our customers with an unmatched passion for excellence and innovation since the establishement of our company. We will always keep researching and innovating in the fastest-growing market and make sure us and our customer to be the leader of our industry. We insist on reform and innovation to maintain the passion of employees and the vitality of the organization.

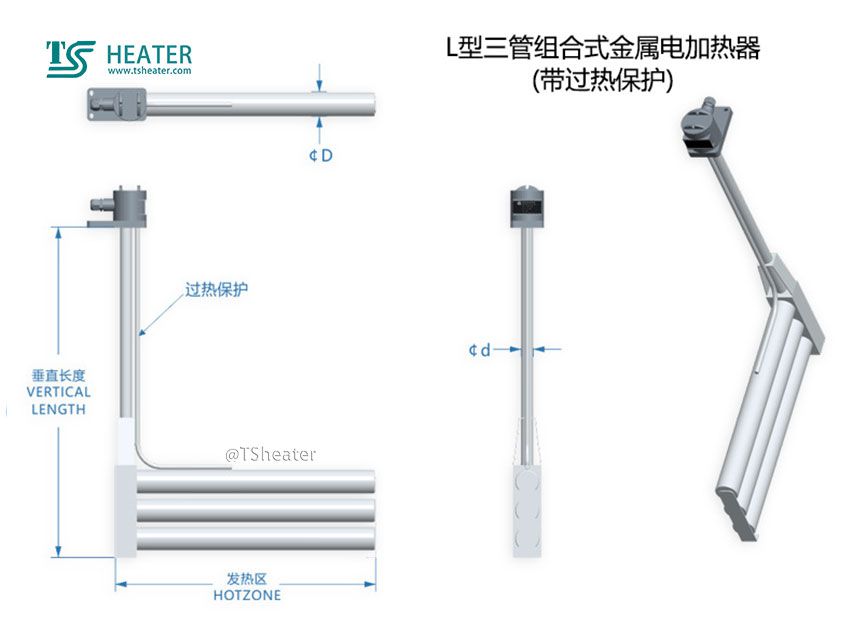

1. Titanium, zirconium, SUS304, SUS316 stainless steel tubes are used.

2. Design the surface power of the heating tube and determine the pipe diameter according to the installation location, chemical liquid properties and solid substance deposition characteristics in the liquid. Common specifications for pipe diameter are Ø 11 mm, 17 mm, 25 mm, Ø Ø Ø 30 mm, Ø 32 mm and 45 mm, Ø Ø 50 mm.

3. Submersible Oil Heater, liquid heating, heating tube surface power 5.6 W/cm2, suitable for liquid and solid deposit less, not in the heater surface cooled liquid crystalline liquid heating.

4. 45 mm diameter Ø series of products with low power design surface, good durability, especially for horizontal heating circuit board.

5. The voltage is 120V single-phase, 220V, 380V, 220V three-phase, 380V three-phase, power from 0.5kW to 140KW.

6. All heaters can be equipped with overtemperature protection switch or temperature sensing probe.

7. All heaters adopt international inspection standards to ensure safe electrical performance

Applicable environment: all kinds of electroplating corrosion liquid, due to the difference in steel selection.

Specification design: you can refer to the list of common specifications, or according to customer requirements to design various shapes, specifications, processes, etc.

For details, please consult our engineers and technicians

Our company integrates many years of professional sales and on-site practical experience in the field of Micro Membranes 10 Microns 40 Inch Fiber Glass Cartridge Filter Element for Grape Wine Filtering Machine, vigorously enhances the added value of products for our respected customers, and reduces cost consumption. We will continue to enrich and improve our product line in order to provide better service and meet market demand, and gradually move towards a diversified corporate path. We continue to invest a lot of manpower, material resources and financial resources to rationally arrange production space to ensure orderly and smooth production.