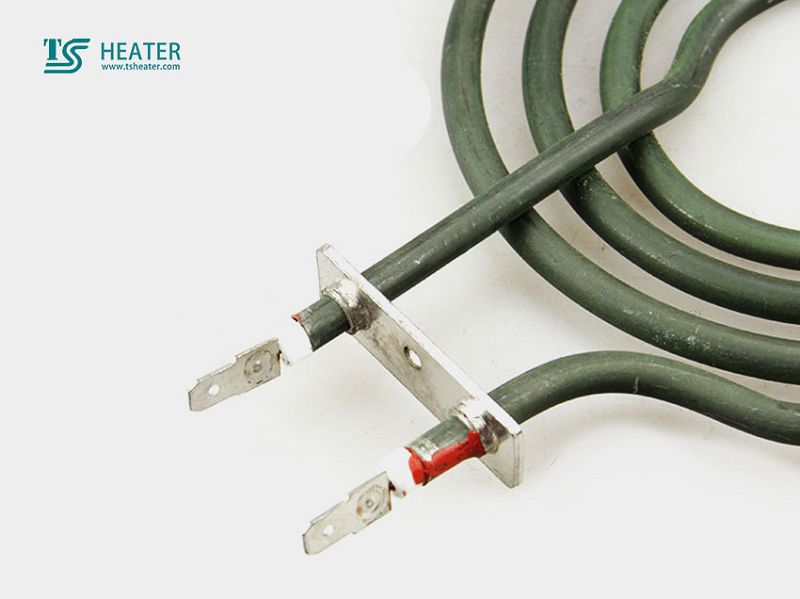

Grill heating elements has simple structure, high thermal efficiency, good mechanical strength and good adaptability to harsh environment.It can be used for heating all kinds of liquids and acid, base and salt as well as for melting metals (lead, zinc, tin,) with low melting point.Grill Heating Elements

We emphasize development and introduce new products into the market every year for temperature cable, electric finned tube radiator, barrel heating jacket. With first-class product quality and considerate service, our company maintains a sustained and stable development, and our brand awareness has increased year after year. Knowledge, flexibility, strong technical leadership and a commitment to excellence are the core principles of our company. These principles strengthen strong customer relationships and bring outstanding results. The importance of core employees to the survival and development of the company is beyond doubt, thus we are committed to improve the ability of employees.

Grill heating elements has simple structure, high thermal efficiency, good mechanical strength and good adaptability to harsh environment.It can be used for heating all kinds of liquids and acid, base and salt as well as for melting metals (lead, zinc, tin,) with low melting point.

Electrical strength test:

A. Electrical strength in cold state: it shall be able to withstand 50Hz,1min withstand voltage, cut off current 5mA, without breakdown and flashover.

Rated voltage test voltage 250V 1250V

B. Electrical strength at operating temperature: 50Hz,1min withstand voltage, cut off current 5mA, no breakdown, flashover.

Rated voltage test voltage 250V 1000V

3. Leakage current at operating temperature

Under the condition of full heat release, the leakage current of the electric heat pipe is 0.5m A, with the input of 1.15 times rated power.

4. Overload test

Under the condition of sufficient heat release, the electric heat pipe is powered on with 1HRS of rated power 1.27 times, and cooled with 0.5HRS to room temperature (forced cooling is allowed) after power failure, so that the cycle is repeated for 30 times without damage.

5. Enclosure sealing test of electric heat pipe (pipe crack test)

The electric heat pipe shall be immersed in 3HRS of acidified water (2%-3% hydrochloric acid, sulfuric acid or nitric acid). The two end faces of the electric heat pipe shall be exposed to at least 5mm of liquid level. After testing, the performance requirements of item 2~3 shall be satisfied.

6. Sealing test

The electric heat pipe shall be placed at 24HRS in an environment with a temperature of 60℃ and a humidity of 95%, and shall meet the second to third performance requirements after being placed.

7. Life test

Under the condition of sufficient heat release, the electric heat pipe is powered on by 1HRS at rated voltage, and cooled by 0.5HRs to room temperature (forced cooling is allowed) after power off. The accumulative working time is up to 3000HRs.

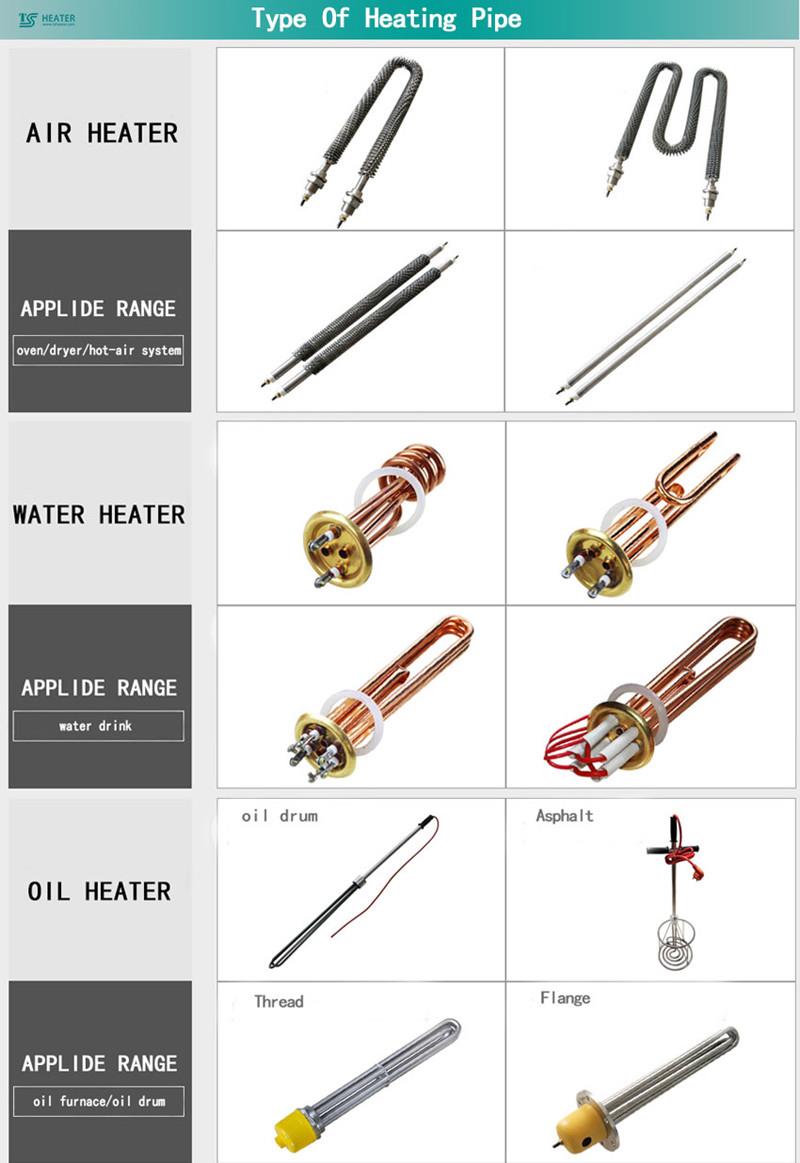

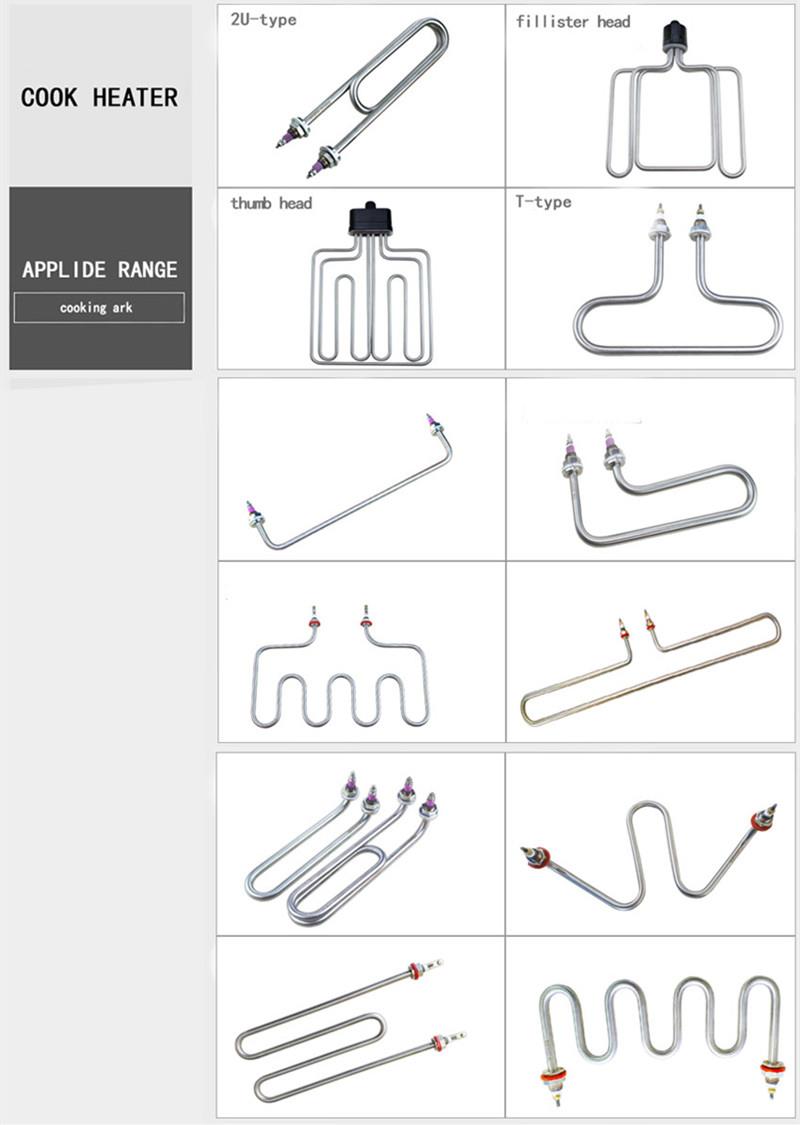

Type of industrial tubular heaters:

TS heater Founded in 2009, belong to factory investment company, with strong technical & products knowledge support. TS focused on electric & industry heaters’ technology research, development,co-production and sales. Mainly engaged in electric heating tube,shaped tubular heater ,cartridge heater, Teflon heater, Hot runner heater, cast in aluminum/iron/brass heater,,Thermocouple, TC ,RTD pt100, Nickel Chrome Cr20Ni80, Heating cable, Blanket Drum heater, Silicone heater, Mica band heater, Ceramic heater, ........

All the products are widely used in electroplating, chemical, plastics, machinery

We have established a product research and development center to lay a solid foundation for continuous improvement of Pin Tube Style Immersion Heater for Oil Tank. We hope that the economic and social benefits of our company will be balanced to achieve sustainable development of the company. In the spirit of the world as a teacher, we will learn forever, practice hard and strive for success with heart. We will make every step towards our ideal more solid, and paint a better tomorrow.