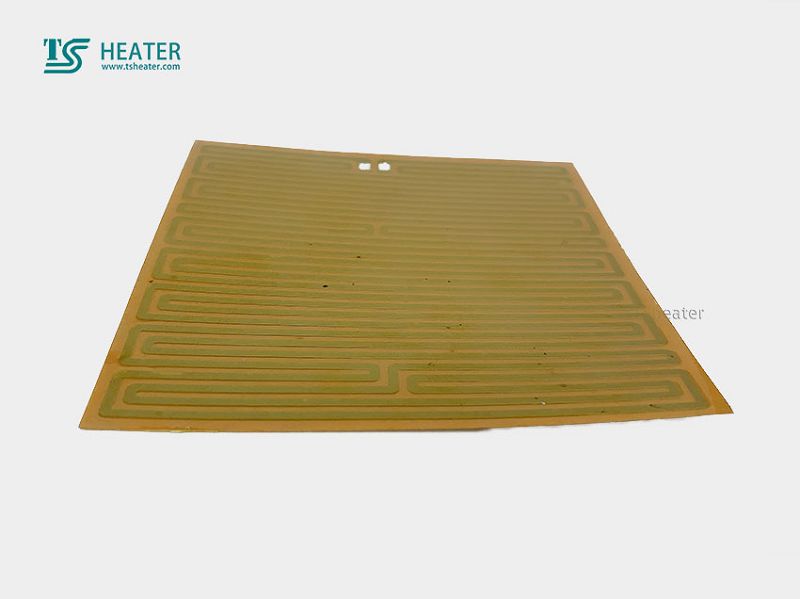

Polyimide film thin heater is an organic film with very high dielectric capability, thin profile and low thermal mass, while providing superior resistance to most solvents, acids, and radiation. In connection with these features Polyimide Film Thin Heating

'Based on domestic market and expand overseas business' is our improvement strategy for replacing hot water heater element, thermal coupling wire, air finned heater. Our company has an elite team with excellent technology and unity. From product development to shipment, we strictly control every link to make customers satisfied. We have various excellent employees, responsible for product development, design, production and sales.

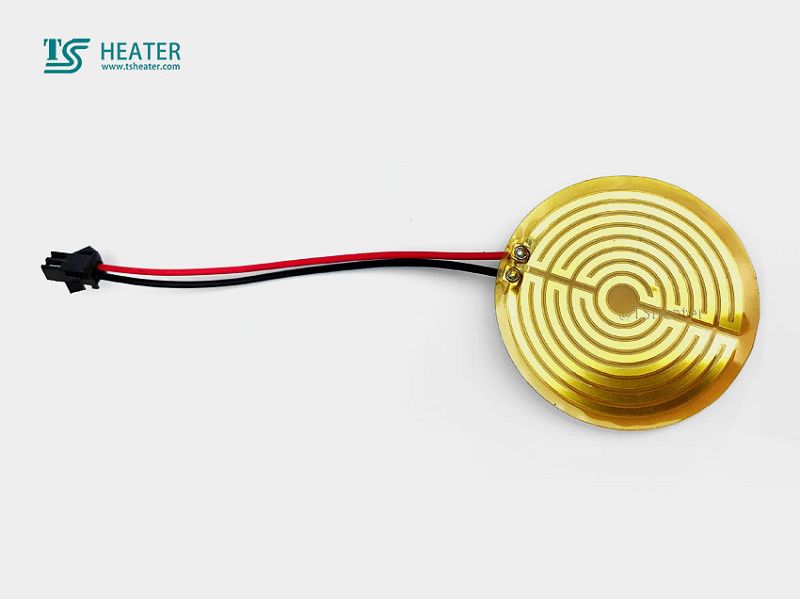

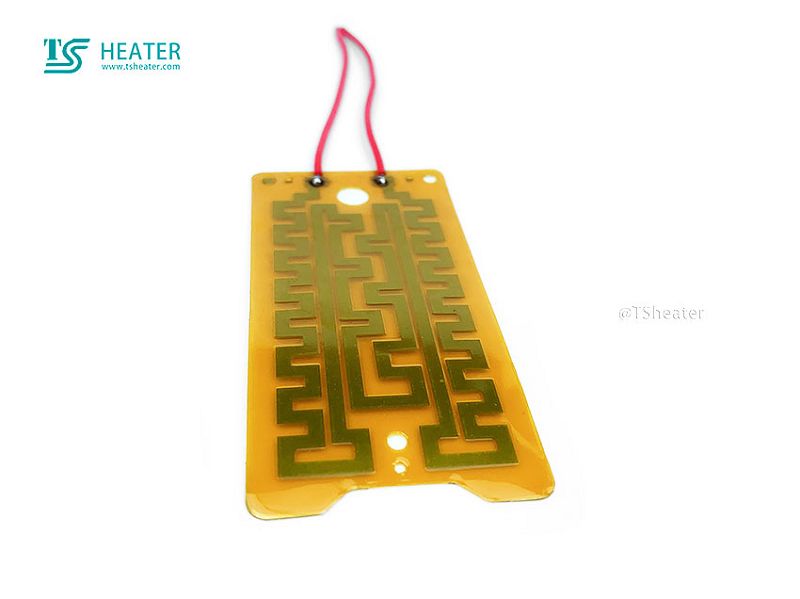

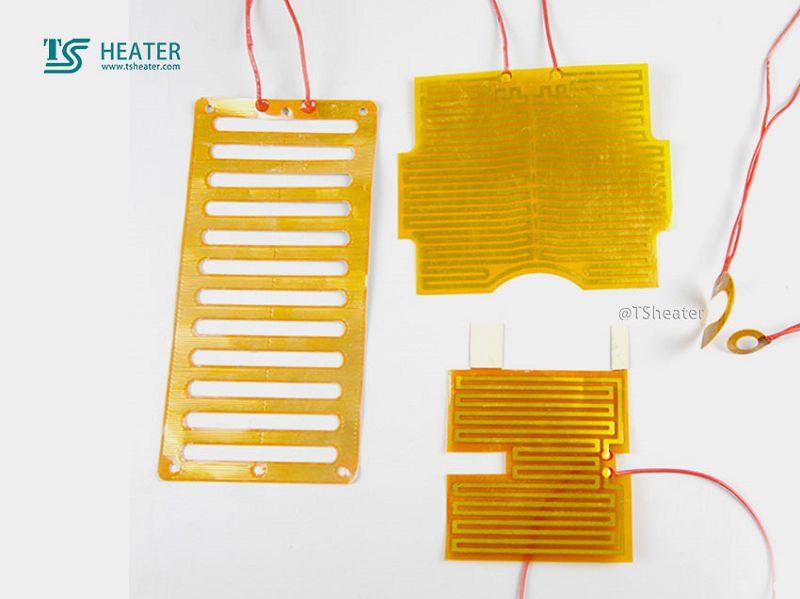

Polyimide film thin heater is an organic film with very high dielectric capability, thin profile and low thermal mass, while providing superior resistance to most solvents, acids, and radiation. In connection with these features, Polyimide (Kapton Film) heaters are very ideal for applications

with space and weight limitation: total thickness ≤0.2mm; bending radius ≥0.8mm

be exposed to chemicals or oil

in vacuum environments requiring low out-gassing

fast and precise heating Polyimide Film Thin Heating

Features: Polyimide Film Thin Heating

1.Fast Preheating Speed

2.Long Using Life

3.Space Saving

Applications: Polyimide Film Thin Heating

1.Scientific Analyse Instrument:such as provide constant temperature source for thermal conductivity tester,medical instrument;stabilizing electronic component operating temperature

2.In deep cold circumstances,letting instrument reach safety operating temperature,such as satellite,spacecraft and airplane etc

3.Vacuum heating and baking

4.Car rearview defroster,antenna or radar defrosting heating components and speed regulation resistor

5.Medical treatment and beauty equipment

Benefits Polyimide film thin Heaters: Polyimide Film Thin Heating

Maximum operating temperature of 260°C

Provide heat where it’s needed to reduce operating costs

Fast and efficient thermal transfer

Uniform thermal performance by custom profiling

Customized options for turnkey thermal solutions

Due to the above material properties and benefits, custom/bespoke kapton (polyimide) film heaters have a vast number of applications. It is this combination of useful properties at temperature extremes that makes Kapton a unique industrial material. Listed below are just a few of the applications where kapton heater circuits are used.

# Medical applications, typically requiring clean and sterile environments - Medical Imaging, Medical Diagnostic Instruments and Analyzers, MRI Equipment

# All types of heating applications for electronic components - LCD displays, photocopiers and photographic equipment, ATM's, computer equipment, 3D printers

# Evironmental control and maintenance of electronics - in telecommunications equipment (such as antenas, microvave repeaters and back-up battery systems), electrical panels and enclosures

# Heating of Aerospace/Defence Instrumentation where low outgassing properties are required - Aviation instrumentation and personal comfort heating, Satellites, Spacecraft, Satellite Dish

# Industrial Applications such as heating of Electronic Enclosures, Heaters for motors, cold storage equipment, freeze protection

# Transportation - kapton heaters for Over the Road Truck and Railcar Freeze Protection, Battery and Oil Heating, Auto and Motorcycles

# Applications in the Energy Industry - Fuel Cells, Battery Systems, Power Meters, Transmission Switches

# Printing Equipment Industry, Optical and Photograghic equipment, cameras

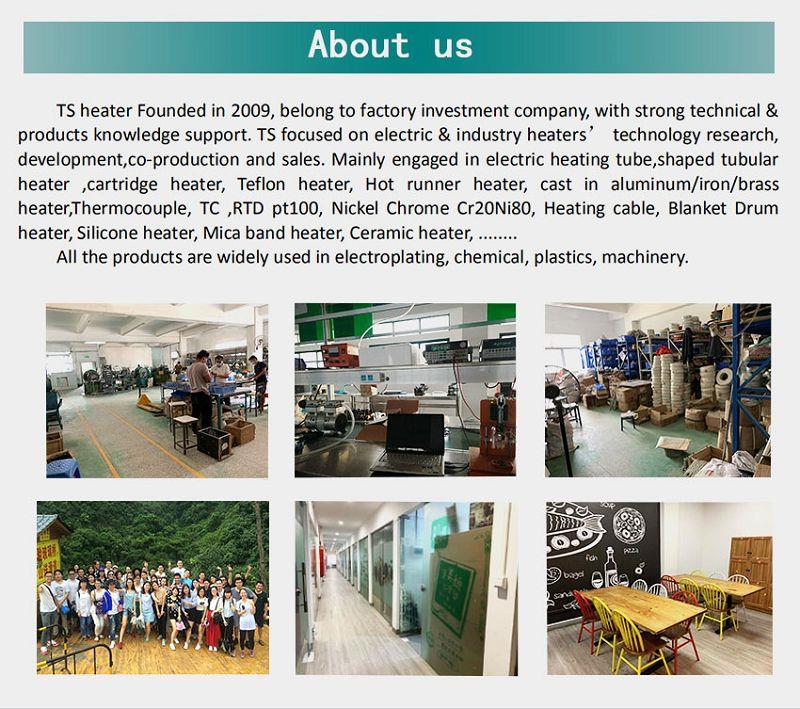

Factory Show

We hope that by improving our management level and work efficiency, we can provide customers with high-quality Polyimide Film Heater Infrared Heater for 3D Printer and further enhance the competitiveness of our company. Our factory adheres to the enterprise spirit of 'focusing on morality, pragmatic and innovative', and constantly strengthens the overall quality of the enterprise, and provides good products and services to all sectors of society. We continue to strengthen our technical force to achieve reductions in staff and efficiency, optimize labor costs, and improve operational efficiency.