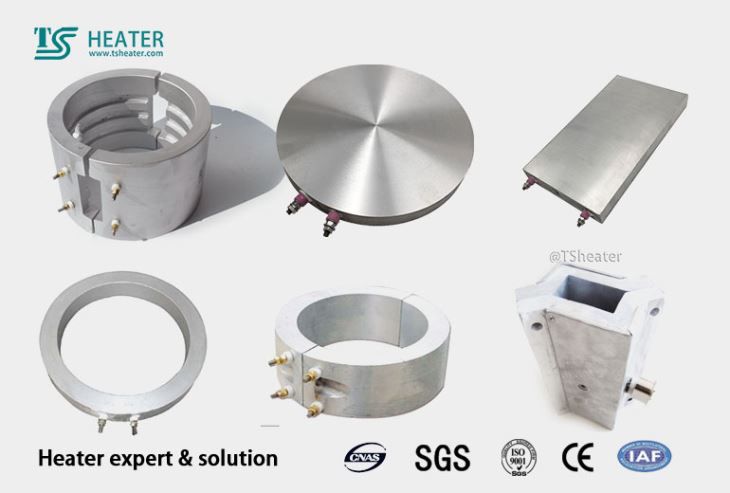

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round,Aluminum Casting Heater

In the face of the fierce market competition, we will be perfecting our own management and developing direction constantly, in order to make our cast aluminum heaters, delonghi mica heater, rcbs swaging die capture the international market rapidly. Our company has many years of production and sales experience and we can well understand and cooperate with customers' needs and make response. Our network e-commerce marketing platform is in progress, and we attach great importance to cross-border e-commerce promotion. Based on standardized management and stable operation, we always put the interests of customers first. The reputation of customers is our best advertisement. We are willing to work together with new and old customers to create brilliant!

Aluminum Casting Heater

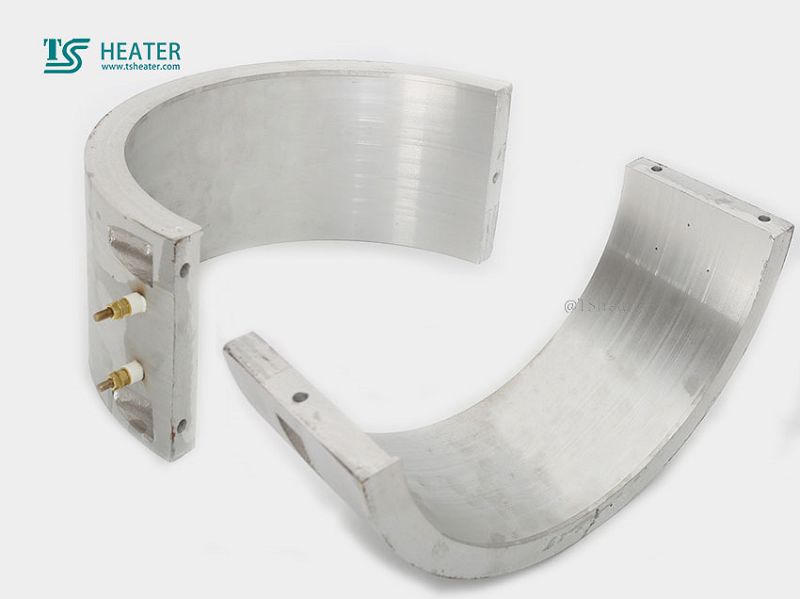

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round, flat, rectangular, air-cooled, water-cooled and other special-shaped etc..

Aluminum Casting Heater

After finishing it and heated body tightly, Metal casting heater is a kind of high efficiency heat uniformity division of the heater, thermal conductivity, excellent metal alloy, ensure the hot surface temperature uniformity, eliminating equipment hot and cold spots. With long life, good insulation properties, mechanical properties, corrosion resistance, magnetic resistance etc..

Aluminum Casting Heater

The outer radiating surface increases thermal insulation device, within the radiating surface of sintering infrared which can save 35% of electricity

Feature:

Aluminum Casting Heater

1.Cast aluminum surface load can reach 2.5-4.5w / cm2, maximum operating temperature 400-500 °C;

2.Cast copper surface load can reach 3.5-5.0w / cm2, maximum operating temperature 600-700 °C;

3.Cast iron surface load can reach 4.5-6.0w / cm2, maximum operating temperature 800-850 °C.

Customers’s cast in heater,ready to send out:

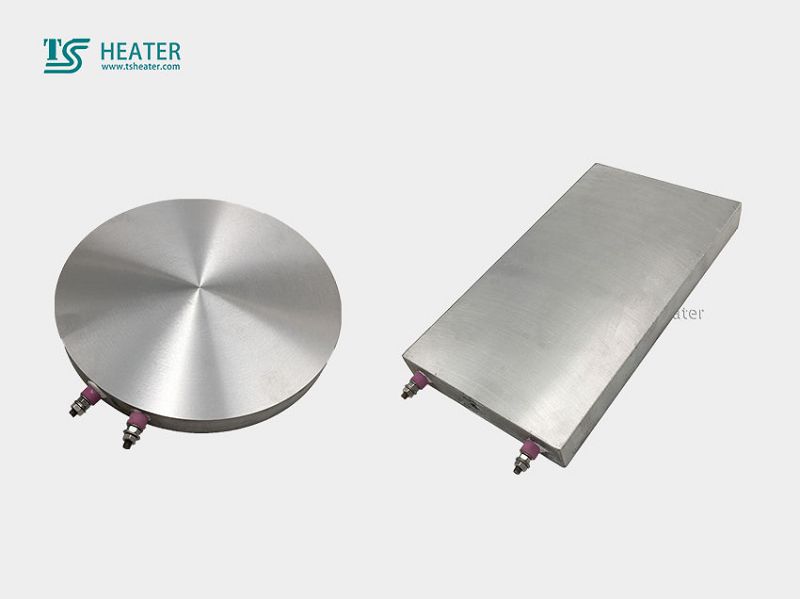

Our clients can avail a variety of Cast Aluminium Plate Heater from us. These plate heaters are designed by engineering experts working with us to suit requirements of different types of industries and client. These heaters are constructed using high-class aluminium which is procured from reliable vendors. Our heaters are highly praised for its complex designs and durability. We also offer customized solutions of these heaters understanding requirements and specifications of clients.

These attempts include the availability of customized designs with speed and dispatch for Prefabricated Steel Construction Warehouse-Ce (SSW-13). Our company has seen a lot of changes in the past years of business. Through the joint efforts of all employees for many years, we have gradually won more and more support from customers, so that our performance has been improved every year. We will still work hard to achieve a win-win situation for both of us.