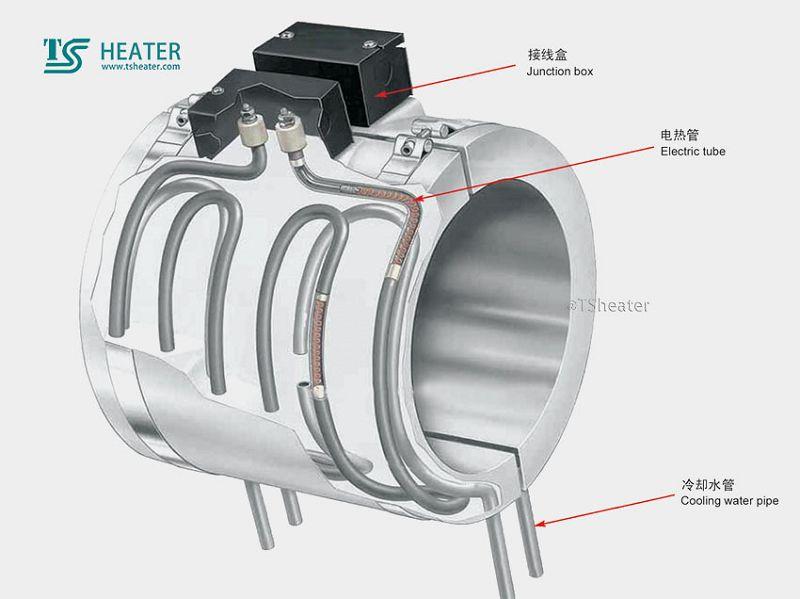

Cast aluminum heater is mainly used for extrusion and casting moulding machines. It has a wide application in various machinery industries. The operation temperature can reach up to 300°C (Aluminium).Cast Aluminum Heaters

Our company adheres to the business principle of 'survive by quality, develop by reputation', create first-class quality, and constantly provide economical and practical 55 gallon plastic drum heater, mainstays ceramic tower heater, air duct heater and efficient and perfect after-sales service according to the needs of customers. We have been wanting forwards to creating long-term company interactions with around the world shoppers. We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we are looking forward to building up a great business relationship with you. We consistently implement the concept of creating value for customers, and we provide products with competitive prices under the premise of ensuring high quality to meet the needs of different customers.

Cast aluminum heater is mainly used for extrusion and casting moulding machines. It has a wide application in various machinery industries. The operation temperature can reach up to 300°C (Aluminium).

Cast Aluminum Heaters

In order to concentrate the heat to one direction on the injection face, the other sides of the casting heaters t are covered by heat retention and heat insulation materials. So it has advantages such as advanced technology, high heat retention, long lifetime, anti-pollution, etc.

It is widely used in plastic extrusion, chemical fibre, blowing moulding machines.

Technical Parameters

Cast Aluminum Heaters

1. Conditions of use: ambient temperature -20 ° C ~ +60 ° C; relative humidity < 80%.

2, Electrical strength: can pass the voltage 1500V50HZ sinusoidal AC voltage withstand test, 1M1N without breakdown phenomenon under pressure.

3. Leakage current: <0.5MA.

4. Insulation resistance: >2MΩ.

5. Grounding resistance: <0.1Ω.

6, Power deviation value: +5% ~ -10%.

7, Temperature resistance: installed on the surface of the machine can be nearly 400 ° C.

Advantage

Cast Aluminum Heaters

1.It can be closely attached to the heated body.

2.Uniform heating

3.Good thermal conductivity

4.Long service life.

Client’s order ready to ship out:

Order Guide:

Please specify the following when ordering.

The inner diameter (mm) and length (mm) of heaters

Thickness of heaters

Terminal length (max & min) and the distance of terminal length

The diameter, length of cooling tubes and the distance between them.

Voltage and power density

Gap of two pieces if applicable

Wiring type and position

Whether need air blowers

Content of the stamping if needed

Order quantity

Delivery date

* It's better to provide us with the drawings/pictures

Others: position of terminal box, the position and size of the hole for connecting thermocouple OR of the incision, whether need to cast in the terminal

Our firm aims to operating faithfully, serving to all of our shoppers, and working in new technology and new machine regularly for Side by Side Freezer Defrost Heater with Aluminum Foil Heater. We take the pursuit of operating profit growth as our goal, and we are also committed to seeking a win-win situation between the company and society. Our company has a complete integrated service system.