Ocr25Al5 Wire Widely used in industrial furnace, household appliances, metallurgy, machinery, aircraft, automobile, military and other industries to produce heating elements and resistance components. Ocr25Al5 Wire

We have quite a few great team customers very good at internet marketing, QC, and dealing with kinds of troublesome trouble while in the output approach for k type thermocouple socket, tubular air heater, ceramic heating panels. We hope that all employees will work together to constantly surpass themselves, improve the working atmosphere of the company, and create a good corporate culture. We establish long-term supporting relationships with preferential prices and excellent after-sales service. We are introduced as a one of the growing manufacture supplier and export of our products.

0Cr25Al5 resistance electric heating wire

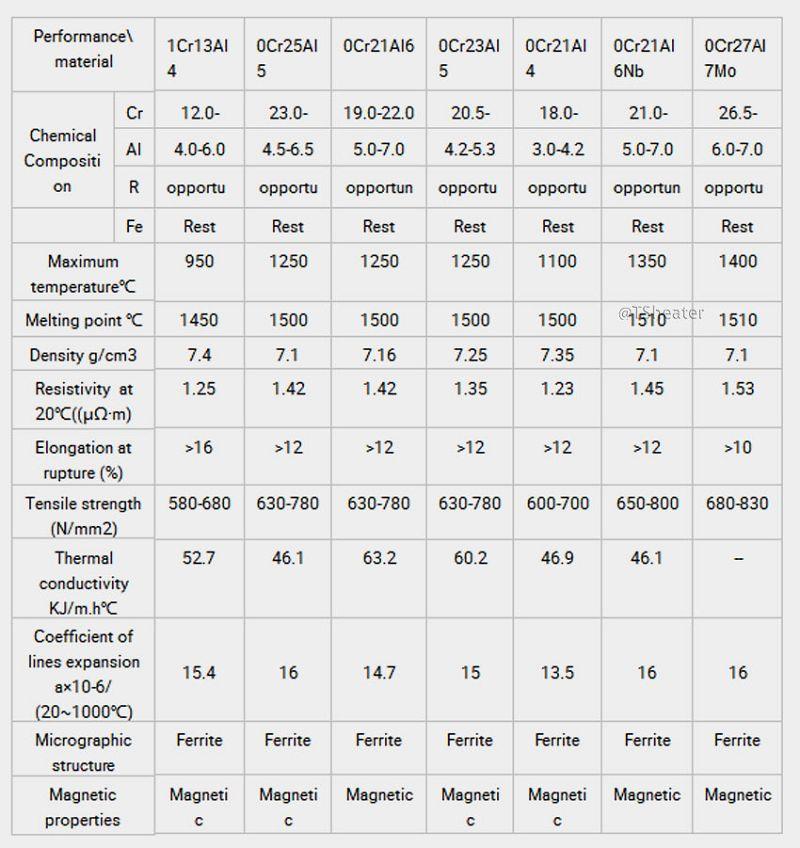

Fekelar alloy has the characteristics of high resistivity, low resistivity, high working temperature, high temperature oxidation resistance and corrosion resistance.

Widely used in industrial furnace, household appliances, metallurgy, machinery, aircraft, automobile, military and other industries to produce heating elements and resistance components.

Resistance wire 0Cr25Al5 / OCr25Al5 ferrochrome alloy

Resistance heating wire is a common material of ferrochrome aluminum alloy.

Fekelar alloy has the characteristics of high resistivity, low resistivity, high working temperature, high temperature oxidation resistance and corrosion resistance.

Widely used in industrial furnace, household appliances, industrial furnace, metallurgy, machinery, aircraft, automobile, military industry and other industries to produce heating elements and resistance components.

Size range:

Ocr25Al5 Wire

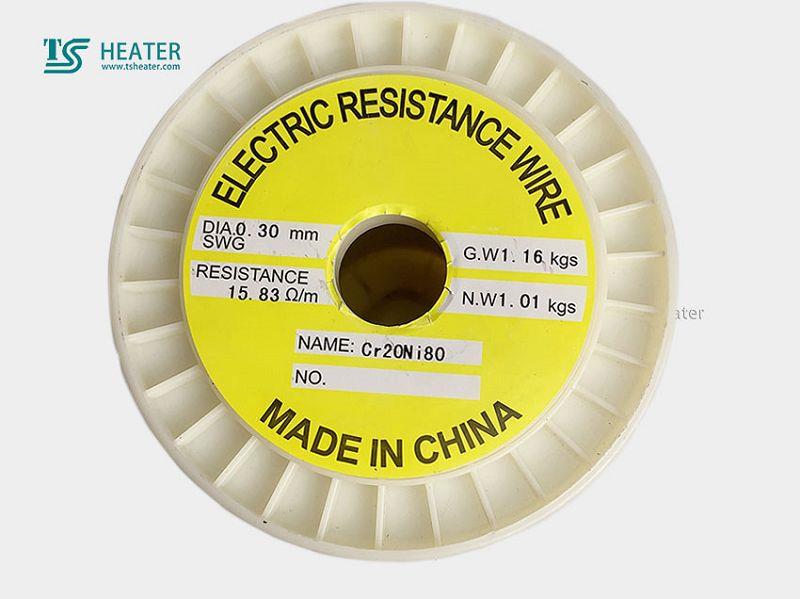

Thread: 0.01 -10 mm

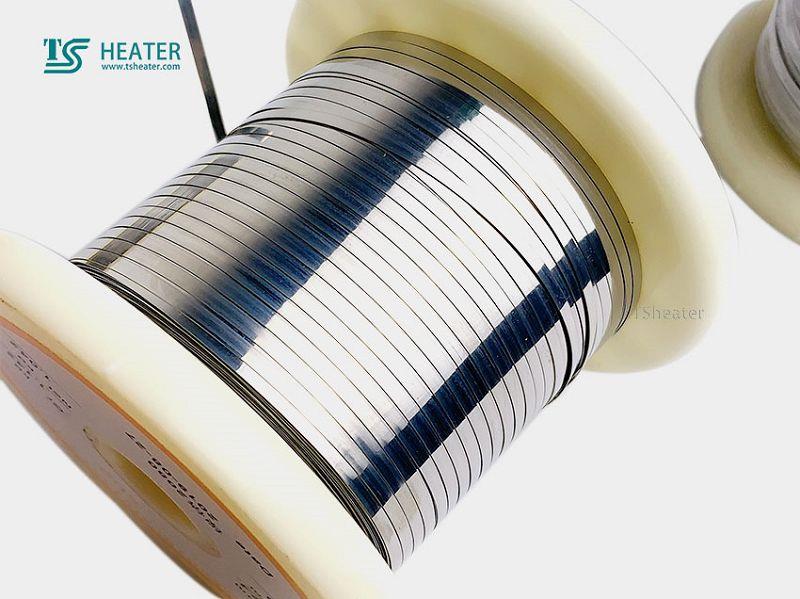

Ribbon: 0.05 * 0.2-2.0 * 6.0 mm

Band: 0.05 * 5.0 -- 5.0 * 250 mm

Bar: 10 to 50 mm

FeCrAl alloy series: OCr15Al5, 1Cr13Al4, 0Cr21Al4, 0Cr21Al6, 0Cr23Al5, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2, etc.

Details

Ocr25Al5 Wire

Place of Origin:GuangZhou, China

Brand Name:TS W

Model Number:0Cr25Al5

Type:Bare

Application:Heating

Conductor Material:Copper Clad Aluminum

Conductor Type:Solid

Surface:Bright

Resistivity:1.42

Maximum Temperature:1250℃

Melting Point:1500℃

Technique:Cold Drawing

Treatment:Hydrogen Annealing

Condition:Soft Annealed

Certificate:ISO9001, SGS

Delivery Time:7-20 Days

Tensile Strength:630-780

Ocr25Al5 Wire

Delivery & Enquiries:

Most items are available for delivery in 3 to 7 working days. However, Ts heater do offer additional emergency services for customers who are in a breakdown situation. This includes a 48hr services on Mica products, Cartridge Heaters and Ceramic Knuckle Heaters. For all enquires please contact a member of our sales team who will be happy to assist.

As a new round of industrial revolution is gaining momentum, we will continue to forge ahead and continuously improve the quality of our Silicone Insulated Cable Nickel 212 Tinned Copper Wire CuNi6 CuNi10. We will continue to uphold the brand belief and provide customers with more cost-effective products and services with a new attitude in the future. We have a strong R&D capability and technical team to make our products occupy the leading position in the fierce market competition in the industry.