The most versatile and the best suited solutions to a large number of applications.In applications where tubular heaters are exposed to forced convection, placing fins around tubular heaters increases their surface area and thus improves their heat transferring capacity.

Looking back at the past, we focus on creating quality finned heating element, silicone fiberglass sleeve, hot runner nozzle and serving customers wholeheartedly, which has led to remarkable achievements. We take the safety and application of consumers as the highest interest. We now have got a skilled engineering group to serve for your just about every detailed needs. If you have the honor to do business with our company. We recognize that if we are going to continue to survive and develop, we have to create our own brand benefits and rely on technology to develop products independently.

As one of industrial heaters, industrial heaters is most versatile and the best suited solutions to a large number of applications.In applications where tubular heaters are exposed to forced convection, placing fins around tubular heaters increases their surface area and thus improves their heat transferring capacity. Finned tube heater , compared to regular tubular heaters,run at lower surface temperatures for the same watt densities when placed in identical air streams.

These heating elements have a strong outer sheath to help protect the heater from physical stress and uses high quality alloys to allow efficient heat transfer from resistance coil to your heating medium.

Features:

It is most widely used in industrial heaters;

* Mild Steel sheath models are suitable for operating temperatures to 500c;

* Stainless steel sheath models are suitable for operating temperatures to 700c;

* High temperature nickel chromium resistance wire;

* Full brazed wound fin;

* Standard and custom options available.

Specification:

Tube Material | Fin Material | Diameter | Fin Height | Fin Thickness | Fin Pitch |

SS304/316/321/Incoloy | S.Steel / mild Steel | Φ6.7 | 3-5 | 0.3-0.4 | 3-5 |

SS304/316/321/Incoloy | S.Steel / mild Steel | Φ8 | 3-5 | 0.3-0.4 | 3-5 |

SS304/316/321/Incoloy | S.Steel / mild Steel | Φ9 | 3-5 | 0.3-0.4 | 3-5 |

SS304/316/321/Incoloy | S.Steel / mild Steel | Φ10 | 5-7 | 0.3-0.4 | 3-7 |

SS304/316/321/Incoloy | S.Steel / mild Steel | Φ12 | 5-7 | 0.3-0.4 | 3-7 |

SS304/316/321/Incoloy | S.Steel / mild Steel | Φ14 | 5-10 | 0.3-0.4 | 3-7 |

SS304/316/321/Incoloy | S.Steel / mild Steel | Φ16 | 5-10 | 0.3-0.4 | 5-10 |

SS304/316/321/Incoloy | S.Steel / mild Steel | Φ20 | 5-10 | 0.3-0.4 | 5-10 |

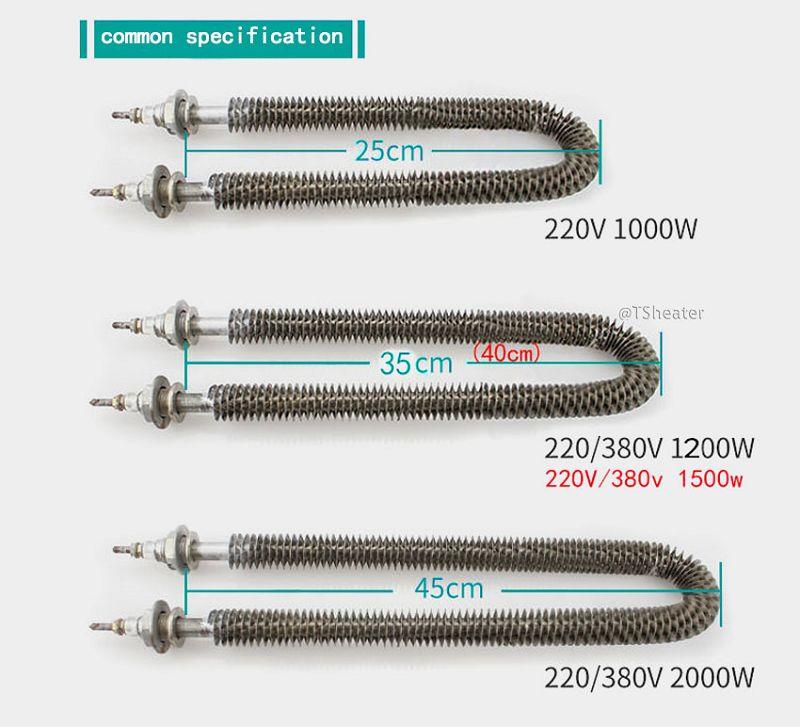

Common specification:

TS heater Founded in 2009, belong to factory investment company, with strong technical & products knowledge support. TS focused on electric & industry heaters’ technology research, development,co-production and sales. Mainly engaged in electric heating tube,shaped tubular heater ,cartridge heater, Teflon heater, Hot runner heater, cast in aluminum/iron/brass heater,,Thermocouple, TC ,RTD pt100, Nickel Chrome Cr20Ni80, Heating cable, Blanket Drum heater, Silicone heater, Mica band heater, Ceramic heater, ........

All the products are widely used in electroplating, chemical, plastics, machinery

We continue to learn advanced technology at home and abroad to open up and develop new markets. We have established a good business reputation and brand image in the Timber Drying Machine Radiator (SRTL-4-12) industry, making us a competitive enterprise. We give priority to quality and customer satisfaction and for this we follow stringent quality control measures. We have a wealth of industry experience, and we use technology and reputation to establish a complete and practical distribution management system.