Submersible Oil Heater,The surface power of the heating tube is 5.6w/cm2, which is suitable for liquid heating with good fluidity, less solid deposition and no crystallization of the liquid on the surface of the electric heater after cooling.

We love an incredibly fantastic standing amid our consumers for heater spring element, 3d printer cartridge heater, x ray machine cost. We have a complete quality control system, advanced design philosophy, strict management of manufacture process. Thanks to this, it is possible to make our product quality stable and reliable. We have a high-quality marketing team, perfect and fast after-sales service, the overall customer network describes the world carefully and we have advanced business philosophy and thinking globalization. We earnestly carry out the contract, and we are a creditable enterprise with good market reputation and honest management.

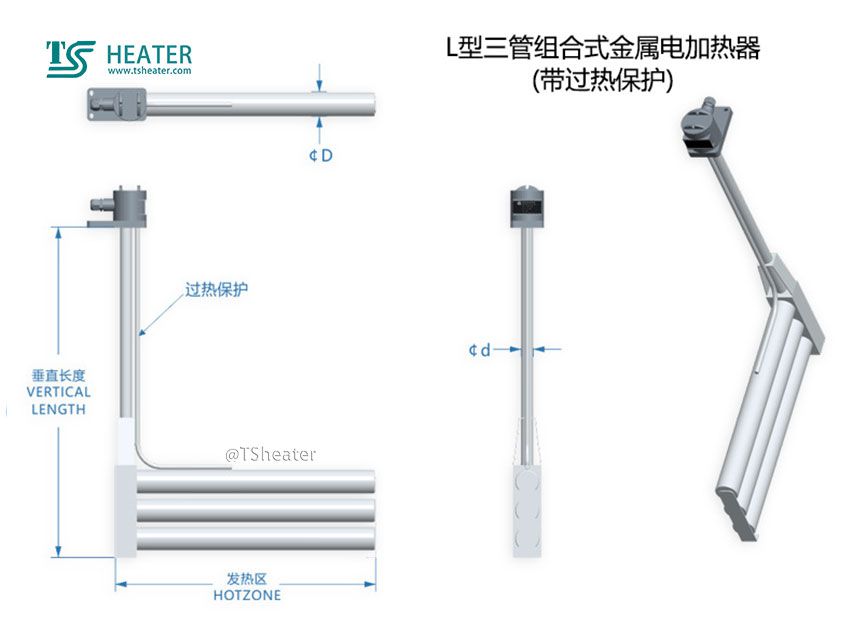

1. Titanium, zirconium, SUS304, SUS316 stainless steel tubes are used.

2. Design the surface power of the heating tube and determine the pipe diameter according to the installation location, chemical liquid properties and solid substance deposition characteristics in the liquid. Common specifications for pipe diameter are Ø 11 mm, 17 mm, 25 mm, Ø Ø Ø 30 mm, Ø 32 mm and 45 mm, Ø Ø 50 mm.

3. Submersible Oil Heater, liquid heating, heating tube surface power 5.6 W/cm2, suitable for liquid and solid deposit less, not in the heater surface cooled liquid crystalline liquid heating.

4. 45 mm diameter Ø series of products with low power design surface, good durability, especially for horizontal heating circuit board.

5. The voltage is 120V single-phase, 220V, 380V, 220V three-phase, 380V three-phase, power from 0.5kW to 140KW.

6. All heaters can be equipped with overtemperature protection switch or temperature sensing probe.

7. All heaters adopt international inspection standards to ensure safe electrical performance

Applicable environment: all kinds of electroplating corrosion liquid, due to the difference in steel selection.

Specification design: you can refer to the list of common specifications, or according to customer requirements to design various shapes, specifications, processes, etc.

For details, please consult our engineers and technicians

To reach a mutual profit of our clients, suppliers, the society and ourselves for Tubular Heater Induction Soldering Machine for Steel Elements. In the development of our company, we try our best to provide competitive treatment for our employees and make greater tax contribution for the local area. We integrate members and partners of different backgrounds, support each other and work together, thus constitute a solid foundation for our career development.