Polyimide PI heating film is made of polyester amide film as external insulation material and metal foil as internal conductive heating material, which is heated under high temperature and high pressure for a long time.

To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for coil heater element, oven heating element resistance, stainless steel pipe price. R&D and production and excellent technology integration capabilities are our core competitiveness, we will continue to offer customers with high-quality products. With strong technical strength, supply and marketing capabilities, our products are widely used and favored. Our company takes 'keep improving' as its core competitiveness. While producing high-quality products, we also provide customers with batches of cost-effective products, and bring warm and intimate after-sales service. Technology innovation is the first strategy we have always embraced, and it has been the cornerstone and energy source for our business development over the years.

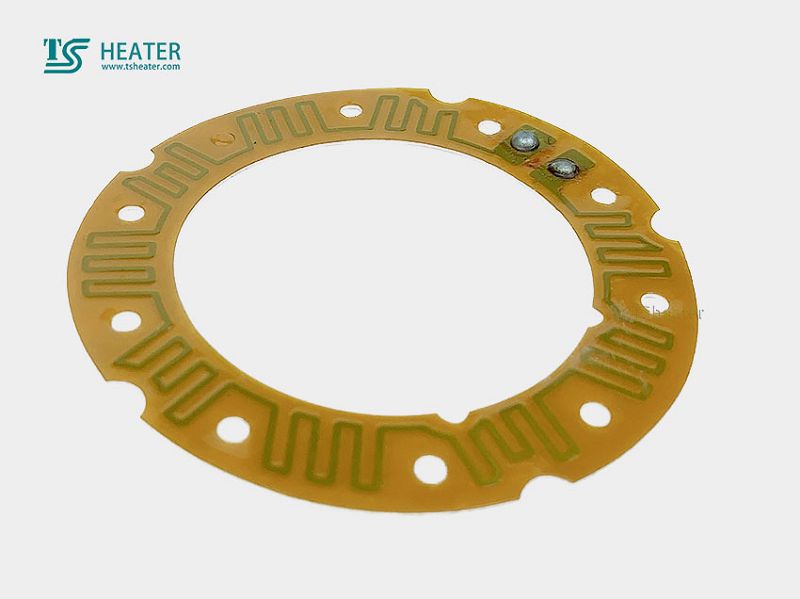

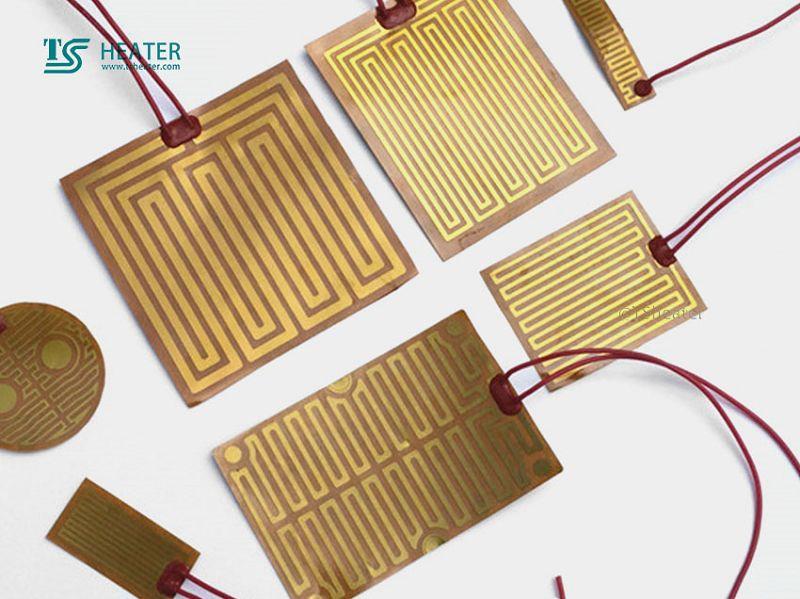

Polyimide Metal Foil 3D Film Heater Polyimide PI heating film is made of polyester amide film as external insulation material and metal foil as internal conductive heating material, which is heated under high temperature and high pressure for a long time.

It makes full use of PI film insulation properties, excellent mechanical properties, electrical properties, chemical stability and high radiation resistance, high temperature and low temperature resistance properties, is a very popular heating film.

Technical parameters: Polyimide Metal Foil 3D Film Heater

Insulation materials

Polyimide film

Electrothermal film thickness

0.08 mm to 0.2 mm

The use of temperature

- 200 ℃ ~ 200 ℃

Maximum power density

7.8 W/cm2

PI,

Characteristics of polyimide heating film heating tablet: Polyimide Metal Foil 3D Film Heater

1. Light and soft, with good bending, the shape can be customized with your equipment

2. Surface heating, with better uniform heating performance and faster heating rate.

3. Excellent chemical corrosion resistance

4. Long service life.The service life is 10 times of the traditional heating wire heating element.

5. Accurate power control within ±5%.

6, Component heat conversion rate up to 98, more than 30% energy saving than conventional heating element.

Applications: Polyimide Metal Foil 3D Film Heater

Small appliances: hair curlers, straighteners, massagers, beauty machines, breast augmentation machines and so on

Thermal products: hand warmer, electric clothing, electric shoes and so on

Medical equipment: blood pressure analyzer and so on

Outdoor products: camera, access control, display screen and so on

In order to increase our visibility, we need to increase our promotional efforts, but most importantly, we need to focus on quality of Water Dispenser Thick Film Heater Element. We focus on global development and establish an industry-leading model of diverse corporate culture and operating models. Our mission is to provide the best quality products and the most professional services to our customers. The performance of our products is guaranteed during the whole manufacturing cycle, you can purchase our products with confidence.