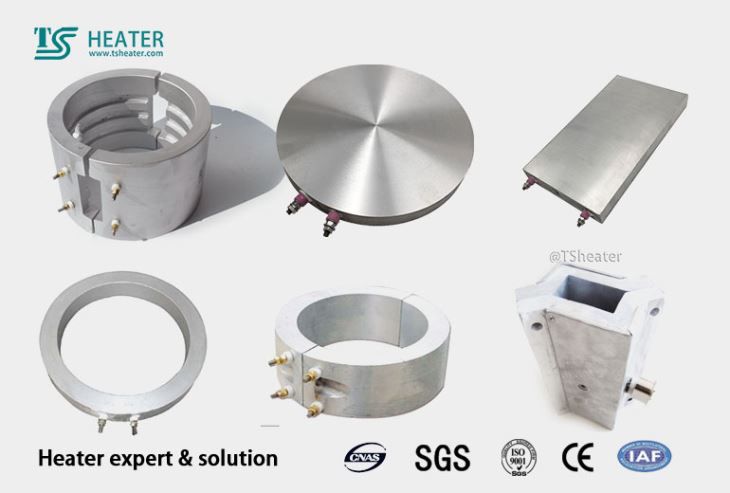

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round,Aluminum Casting Heater

For this reason, we adopt international standards introducing advanced domestic and foreign technical production lines and combining our own rich production experience to ensure heat resistant mat kitchen, programmable thermostat, k type connector is scientific with comprehensive functions. Accurate process devices, Advanced Injection Molding Equipment, Equipment assembly line, labs and software development are our distinguishing feature. A good competitive atmosphere is a catalyst for continuous innovation, thus we need to have the courage to participate in domestic and international market competition, and continue to develop and grow in the competition, so that our company can be full of vitality. In the face of the development of the times and the emergence of unlimited competition, we attach great importance to the cultivation and improvement of the cultural quality of our employees. Our solutions are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Aluminum Casting Heater

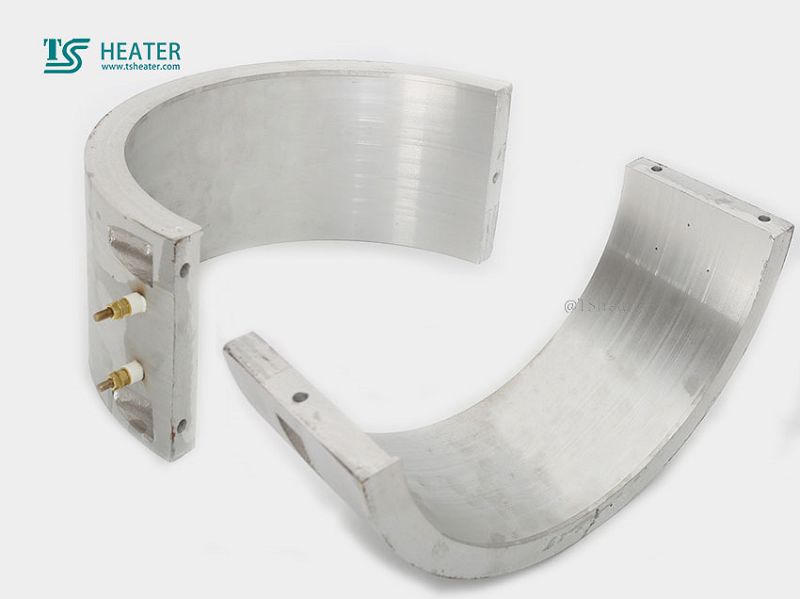

Casting heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round, flat, rectangular, air-cooled, water-cooled and other special-shaped etc..

Aluminum Casting Heater

After finishing it and heated body tightly, Metal casting heater is a kind of high efficiency heat uniformity division of the heater, thermal conductivity, excellent metal alloy, ensure the hot surface temperature uniformity, eliminating equipment hot and cold spots. With long life, good insulation properties, mechanical properties, corrosion resistance, magnetic resistance etc..

Aluminum Casting Heater

The outer radiating surface increases thermal insulation device, within the radiating surface of sintering infrared which can save 35% of electricity

Feature:

Aluminum Casting Heater

1.Cast aluminum surface load can reach 2.5-4.5w / cm2, maximum operating temperature 400-500 °C;

2.Cast copper surface load can reach 3.5-5.0w / cm2, maximum operating temperature 600-700 °C;

3.Cast iron surface load can reach 4.5-6.0w / cm2, maximum operating temperature 800-850 °C.

Customers’s cast in heater,ready to send out:

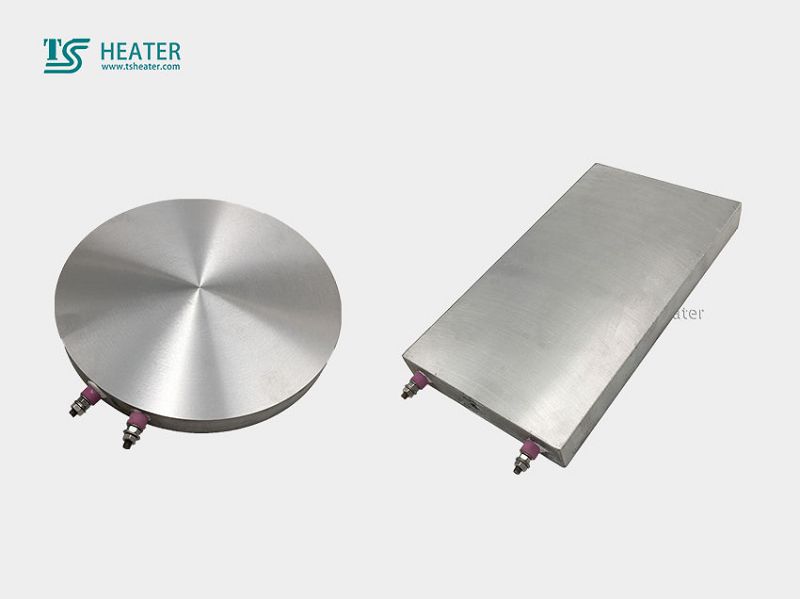

Our clients can avail a variety of Cast Aluminium Plate Heater from us. These plate heaters are designed by engineering experts working with us to suit requirements of different types of industries and client. These heaters are constructed using high-class aluminium which is procured from reliable vendors. Our heaters are highly praised for its complex designs and durability. We also offer customized solutions of these heaters understanding requirements and specifications of clients.

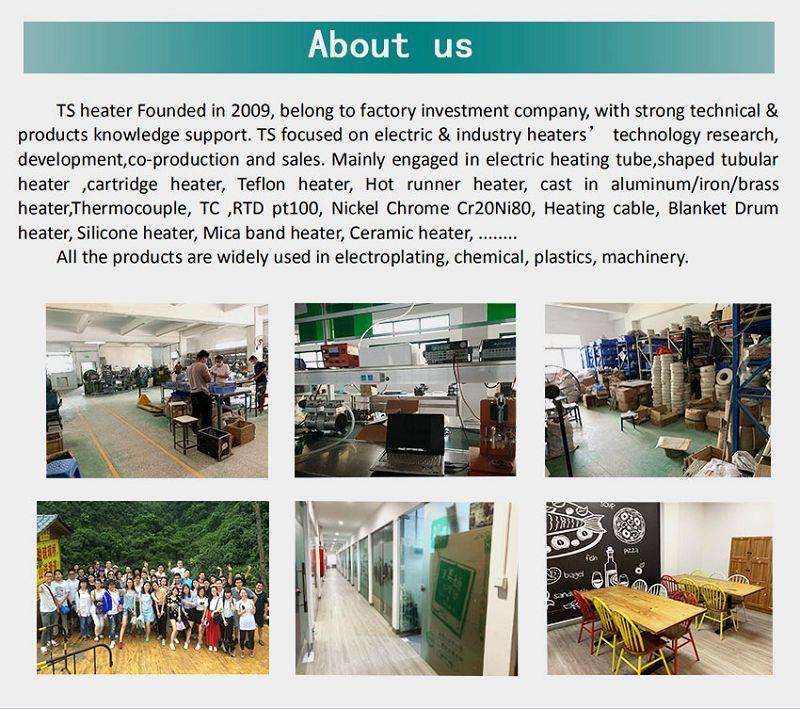

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for Welded Steel Wire Decking by Powder Coated. We are based on the domestic market, open up the foreign market, welcome customers from all over the world to bring our products. Promise is the essence of our corporate culture. We sincerely hope to continue to cooperate with friends all over the world to create industry pioneers.