Depending on their rating, sheath and shape, industrial tubular heaters are used in a variety of industrial heating applications (conduction, convection, radiation heating) that require process temperatures of up to 750°C (1 382°F) to heat liquids, gases and solids.Industrial Tubular Heaters

Owning high-quality products is the basic guarantee for the continuous development of the company. We always pay attention to the continuous development of the resistance of immersion element, water tank heating element, ocr25al5 heating wire industry, strive to be the industry leader, and provide customers with the most cost-effective products. We insist on people-oriented, and hope to provide employees with a good working environment and incentive mechanism. Further, we are supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain.

Industrial Tubular Heaters

Depending on their rating, sheath and shape, industrial tubular heaters are used in a variety of industrial heating applications (conduction, convection, radiation heating) that require process temperatures of up to 750°C (1 382°F) to heat liquids, gases and solids.

Industrial Tubular Heaters

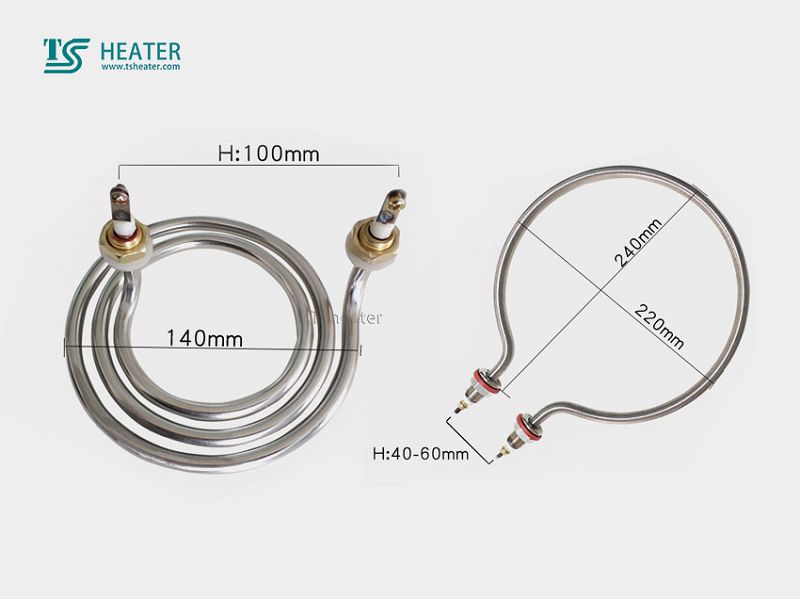

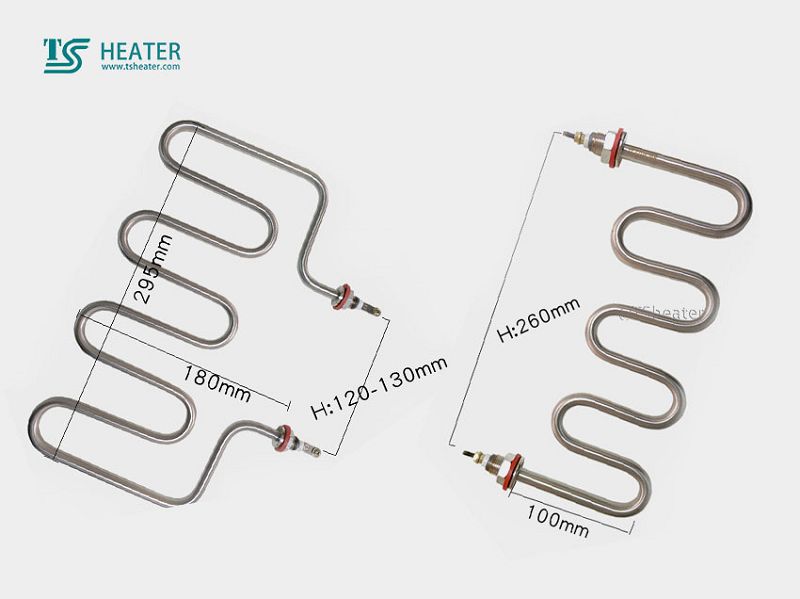

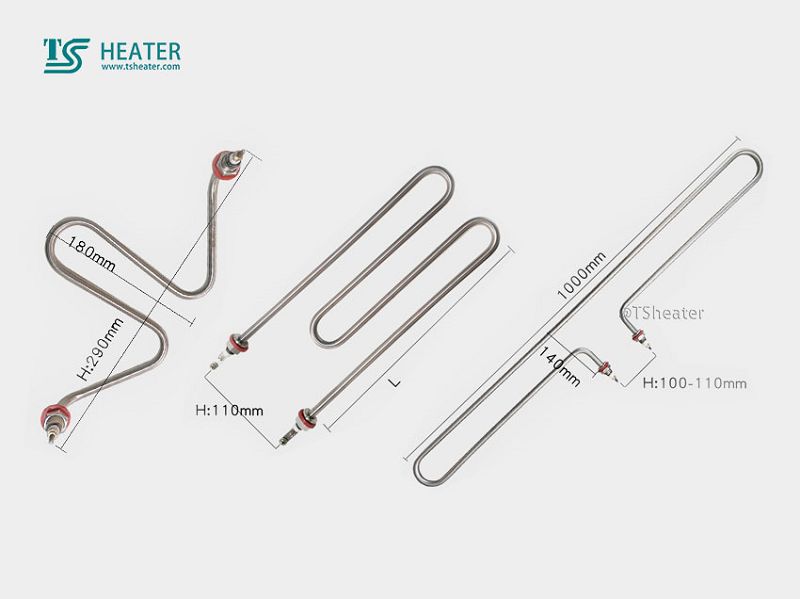

A variety of diameters are available to adjust watt densities in your application and to design your industrial heating product for best performance and long life. Standard and custom made terminal pins allow for easy installation and maintenance. TS heater uses high quality magnesium oxide to allow for efficient heat transfer from resistive coil to your heating medium whether it is air, liquid or solid. Bending radiuses are designed with careful expertise to allow for optimal performance when meeting “form fit and function” within your application,Industrial Tubular Heaters

Specifications: Industrial Tubular Heaters

1.Standard diameters: 0.260 inch , 0.315 inch , 0.375 inch , 0.430 inch , 0.475 and 0.625 inch diameters

2.Available in a broad variety of sheaths, diameters, and ratings

3.Supplied with electrically insulated sheath

4.Provide superior internal electrical insulation and heat conductivity

Benefits: Industrial Tubular Heaters

1.Easy to install

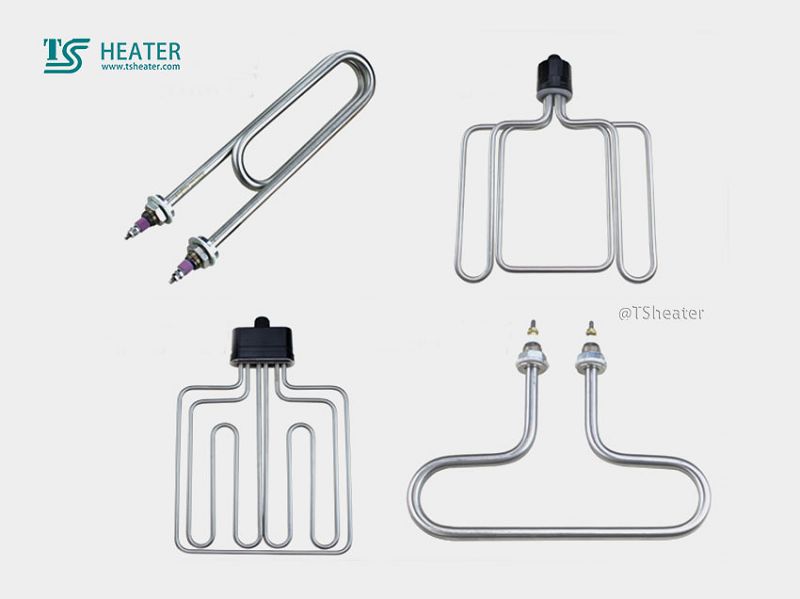

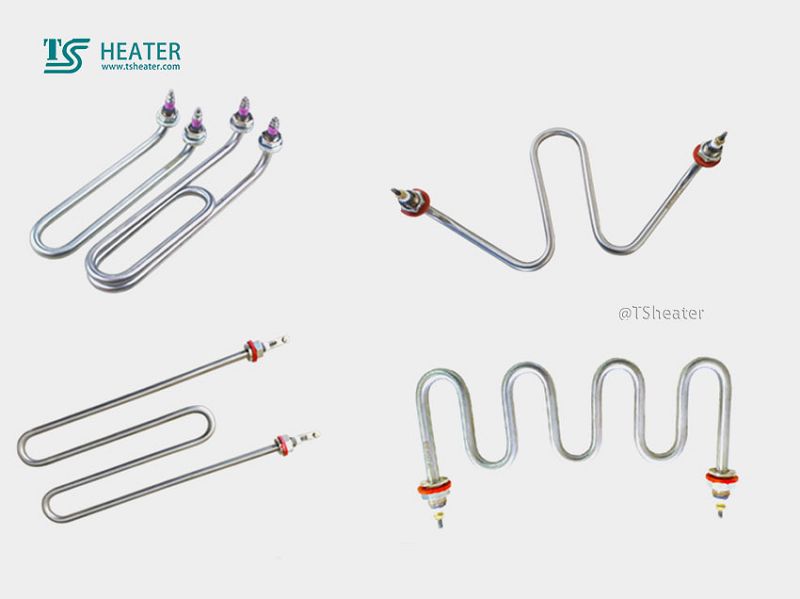

2.Configurable to virtually any shape

3.Compact size

4.Precise and easy control of heat output

5.Durable

6.Easy to maintain

7.Easy to replace thus eliminating long shut-down periods

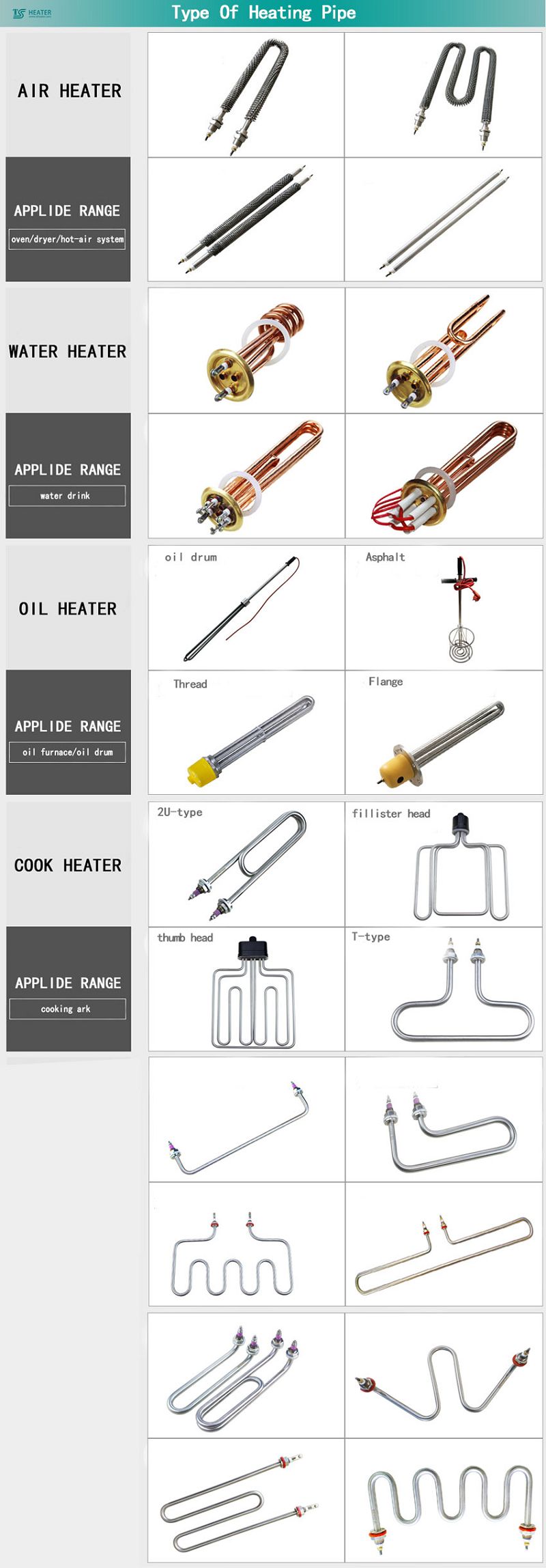

Type of industrial tubular heaters:

TS heater Founded in 2009, belong to factory investment company, with strong technical & products knowledge support. TS focused on electric & industry heaters’ technology research, development,co-production and sales. Mainly engaged in electric heating tube,shaped tubular heater ,cartridge heater, Teflon heater, Hot runner heater, cast in aluminum/iron/brass heater,,Thermocouple, TC ,RTD pt100, Nickel Chrome Cr20Ni80, Heating cable, Blanket Drum heater, Silicone heater, Mica band heater, Ceramic heater, ........

All the products are widely used in electroplating, chemical, plastics, machinery

We are the first-class supplier of Zirconia Porcelain Dental Furnace Ceramic Fiber Heating Chamber Module Heater with Heating Coil based on the tenet of 'pursuing excellent quality and meeting the needs of customers'. With a strict and modern management and a working team that strives for perfection, we ensure the steady growth of market share. Providing customers with high-quality products and satisfying customers is our unremitting pursuit. Since our establishment, we have established long-term cooperative relations with many enterprises with high-quality products, reasonable prices and excellent services.