Variable temperature control is available with the adjustable thermostat with a heating range up to 392ºF. A drum heater is useful for a range of barrel heater options (temperature can vary due to the maximum temperature of liquids).

We will continuously create high quality heater copper, electric water heater coil, quartz patio heater and repay confidence and support to all sectors of society with superior products and services. In the future, we will further increase our development efforts, promote the upgrading of the industry, and bring consumers a more perfect product. We always maintain our responsibilities to customers, distributors and suppliers including business ethics, free and fair trade and ethics in competition.

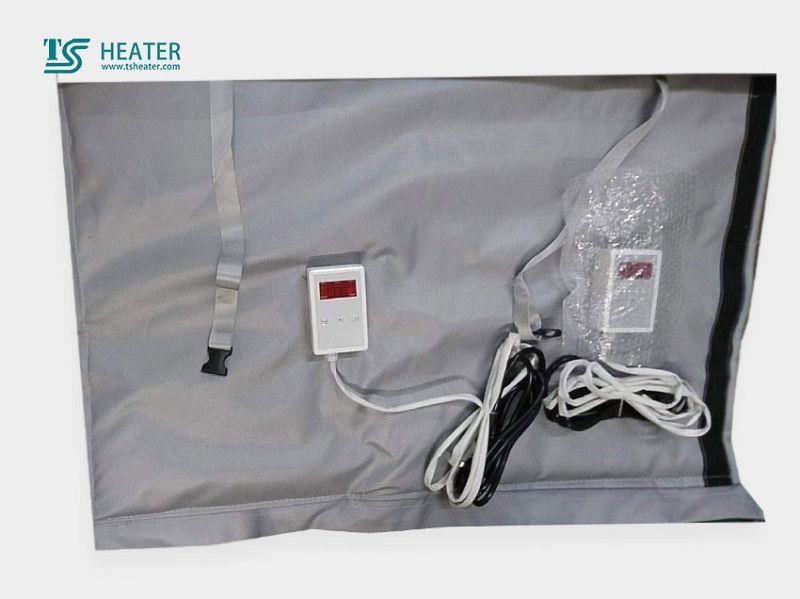

Drum Heater Jacket

Drum heaters are perfect for drums where you want to keep the content at a consistent temperature, a certain viscosity or keeping the content from freezing.

Variable temperature control is available with the adjustable thermostat with a heating range up to 392ºF. A drum heater is useful for a range of barrel heater options (temperature can vary due to the maximum temperature of liquids).

Technical Specifications: Drum Heater Jacket

Thermostat 0-392ºF (0-200ºC)

10 foot power cable

Optimal silicone/glass fabric jacket

High temperature teflon insulated resistance heating wire construction with metal braid

Teflon insulated ground third wire

Insulation: Glass filament materials

Adjustable quick release buckles

Standard sizes.

Thermostat 0-392ºF (0-200ºC)

IP40 approved design

Warm-up duration approx. 28 hours. (55 gallons of water from +60º F to +175º F with a 1200 W drum heater).

The base drum heater may be used additionally

Ideal for heating up: Drum Heater Jacket

Water or oils.

Diesel class fuels.

Wax, e.g. lanolin (wool wax or wool grease).

Suggested use includes using only one drum heater jacket per drum as the heater is designed to be intimate with barrel wall.

The drum heater is designed to perform in applications including industrial liquids made to perform at high temperatures, water, heating oil, diesel fuel preheat, and resin and consistent temperature or viscosity,or materials requiring an optimal preparation temperature prior to usage.

Our raw materials are carefully selected in line with the supremacy of the customers, and wholeheartedly provide customers with quality Barrel Heater Jacket Used on Injection Molding Machine. We are full of confidence with firm faith, down-to-earth products and sincere service and have won a good market reputation. We always take the creation of social value as our mission, unremittingly exploring the law of corporate development and gradually building ourselves into a well-known brand that is ahead of the industry.