Submersible Oil Heater,The surface power of the heating tube is 5.6w/cm2, which is suitable for liquid heating with good fluidity, less solid deposition and no crystallization of the liquid on the surface of the electric heater after cooling.

With our own efficient manufacturing capacity, we ensure that deliverability and the batch sizes of our cast aluminum heaters, heater glass tube, type k thermocouple terminal blocks are in line with the dynamics of our markets at all times. We're likely to be delighted to give you a quotation up on receipt of one's in depth specs. This company cooperates with local scientific research institutions, and has professional production technology, senior research and development talents, adopting strict processing technology and testing methods. Only for accomplish the good-quality product or service to satisfy customer's demand, all of our products have been strictly inspected before shipment.

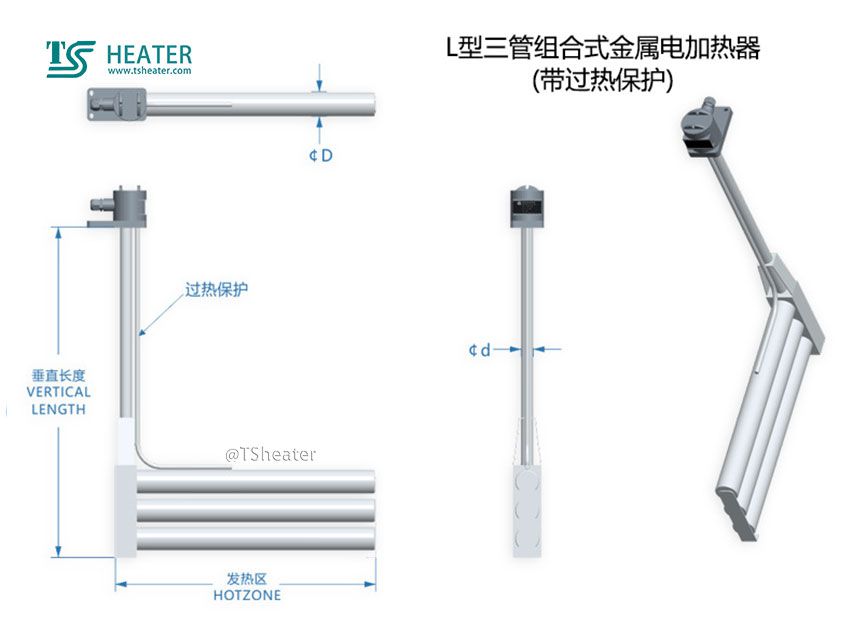

1. Titanium, zirconium, SUS304, SUS316 stainless steel tubes are used.

2. Design the surface power of the heating tube and determine the pipe diameter according to the installation location, chemical liquid properties and solid substance deposition characteristics in the liquid. Common specifications for pipe diameter are Ø 11 mm, 17 mm, 25 mm, Ø Ø Ø 30 mm, Ø 32 mm and 45 mm, Ø Ø 50 mm.

3. Submersible Oil Heater, liquid heating, heating tube surface power 5.6 W/cm2, suitable for liquid and solid deposit less, not in the heater surface cooled liquid crystalline liquid heating.

4. 45 mm diameter Ø series of products with low power design surface, good durability, especially for horizontal heating circuit board.

5. The voltage is 120V single-phase, 220V, 380V, 220V three-phase, 380V three-phase, power from 0.5kW to 140KW.

6. All heaters can be equipped with overtemperature protection switch or temperature sensing probe.

7. All heaters adopt international inspection standards to ensure safe electrical performance

Applicable environment: all kinds of electroplating corrosion liquid, due to the difference in steel selection.

Specification design: you can refer to the list of common specifications, or according to customer requirements to design various shapes, specifications, processes, etc.

For details, please consult our engineers and technicians

We rank in the forefront of the Boiler Replacement Parts Casting Aluminum Heating Plate for Power Plant Hopper Heater industry and enjoy a high reputation. Our products sell well all over the country and many countries. After years of unremitting efforts, our company has established and improved a complete set of production and sales system. Our company insists on trustworthiness of contract, and our production and operation have developed rapidly.