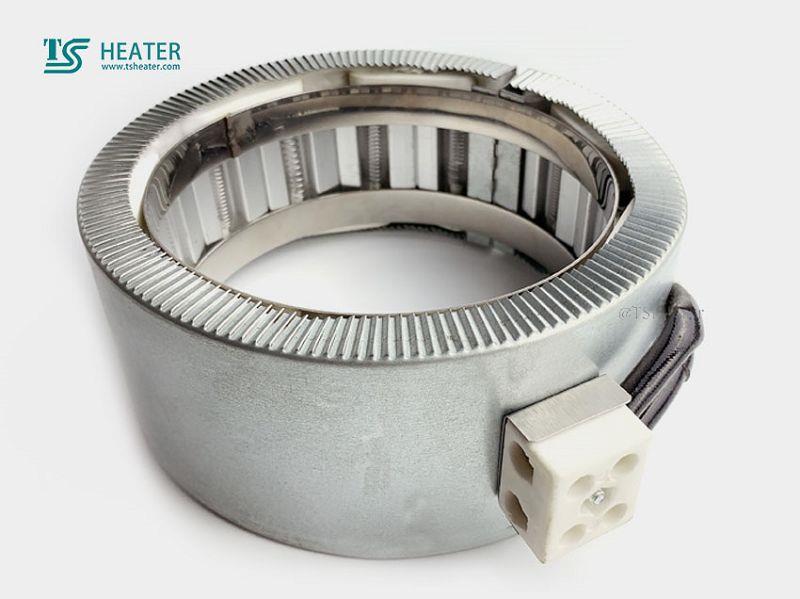

IR energy saving band heater is professional energy-saving device , aim to assist plastic machine increasing the heat efficiency. Utilizing the high resistance heating wire to generate heat and through the infrared radiation way to conduct thermal effect for plastic processing machine.IR Energy Saving Band Heater

We are committed to becoming a world leader in the field of dimplex thermostatic tubular heater, thermocouple compensating cable, alumina ceramic rod. We take 'innovation and improve life' as our core mission, and strive to provide society with high-quality products and services. Our company always adheres to the service concept of 'professional service and value creation', follows the principle of 'no rest in marketing and no distance in service' and takes the maximum satisfaction of users as our goal. We are willing to cooperate with customers at home and abroad on the basis of mutual benefit and seek common development hand in hand.

IR Energy Saving Band Heater IR energy saving band heater is professional energy-saving device , aim to assist plastic machine increasing the heat efficiency. Utilizing the high resistance heating wire to generate heat and through the infrared radiation way to conduct thermal effect for plastic processing machine.

It adopts import electric wire as heating conduction, at maximum extent increase the heat transfer efficiency between heating element and barrel. Electric heat transfer efficiency rate up to 99.8%. The inner use the aerospace grade material air-gel as the insulation material. The surface temperature is under 35℃, which improve the shortcomings for traditional band heater, such as low conversion efficiency of electric heat, low heat transfer efficiency, high temperature in surface etc, thereby the Nano infrared band heater could achieve to saving energy.

Plastic machine nano infrared heater generates high heat by high-resistance wires which is reflected by quartz halogen heating tubes. It has high thermal efficiency, excellent energy-saving effect and quite low heater surface temperature. Following induction heating, it is another high energy-saving heating technology which is now widely used in plastic machines.IR Energy Saving Band Heater

Application range: IR Energy Saving Band Heater

injection molding machine, granulator, extruder, drawing machine, blown film machine and other plastic machinery and other system need to use electric heat.

Features: IR Energy Saving Band Heater

1. 4ultras:ultra-high energy-saving,ultra-low surface temperature,ultra-fast heating rate,ultra long service life

2. Electric heat transfer efficiency up to 99.8%,energy saving rate up to 30% -83%

3. Infrared radiation heating mode, high efficiency, unidirectional radiation

4. The surface temperature is under 35 degrees, greatly improve the operating environment

5. Easy to install and replace,simple and stable structure, the service life of up to 50,000 hours;

Details:

Order guide:

When order IR energy saving band heater ,please kindly inform us the information as following:

1.The inner diameter (mm) (or outer diameter when the heater is used inside) and length (mm) of heaters

2.Width of heaters

3.Voltage and power density

4.Position and size of the hole for thermocouple

5.Wiring type and position

6.Content of the stamping if needed

7.Special gap if Necessary

8.Order quantity

9.Delivery date

We are constantly searching for newer and better methods to continuously improve product quality and service levels. We operate with integrity and are committed to becoming a leader in the China Made High Heat Efficient Poultry Gas Heater industry. To supply prospects with superb equipment and providers, and constantly build new machine is our company's organization objectives. Since its establishment, our company has adhered to the business philosophy of'survive by quality and develope by efficiency' and sticked to the development strategy of'creating branded products', and achieved impressive performance and considerable development in a relatively short period of time.