ptfe heaters,Excellent corrosion resistance. features PTFE casing 304 stainless steel elements are inert to up to 212°F(100°C) in most solutions. Low power density design 10 watts per square inch (1.5 w/cm). 4 ft (1.2 m) continuous fluoropolymer (PTFE) cable connecting steam resistant terminal housing and 3 ft (1.9 m) flexible PVC liquid sealing conduit. Ptfe Heaters

'Honest and trustworthy, seeking truth from facts' is the ethical concept that our company has always followed, and it is also the company's intangible asset. In the tide of market economy, we always adhere to the business philosophy of ensuring quality and mutual benefit to provide customers with high-quality dimplex tubular heater 80w, rcbs swaging die, ceramic infrared sauna/ceramic ir. Our product sales and service are normalized and the product sales chain and service network are densely distributed. We are willing to cooperate sincerely with standardization organizations and various industrial companies to improve the quality of Chinese products and meet the severe challenges of economic globalization. We warmly welcome all old and new customers to visit our company to negotiate business.

ptfe heaters

Excellent corrosion resistance.

features

Ptfe Heaters

PTFE casing 304 stainless steel elements are inert to up to 212°F(100°C) in most solutions.

Low power density design 10 watts per square inch (1.5 w/cm).

4 ft (1.2 m) continuous fluoropolymer (PTFE) cable connecting steam resistant terminal housing and 3 ft (1.9 m) flexible PVC liquid sealing conduit.

Ground internal metal elements and built-in heat protectors.

Recoverable type P3 j thermocouple standard.

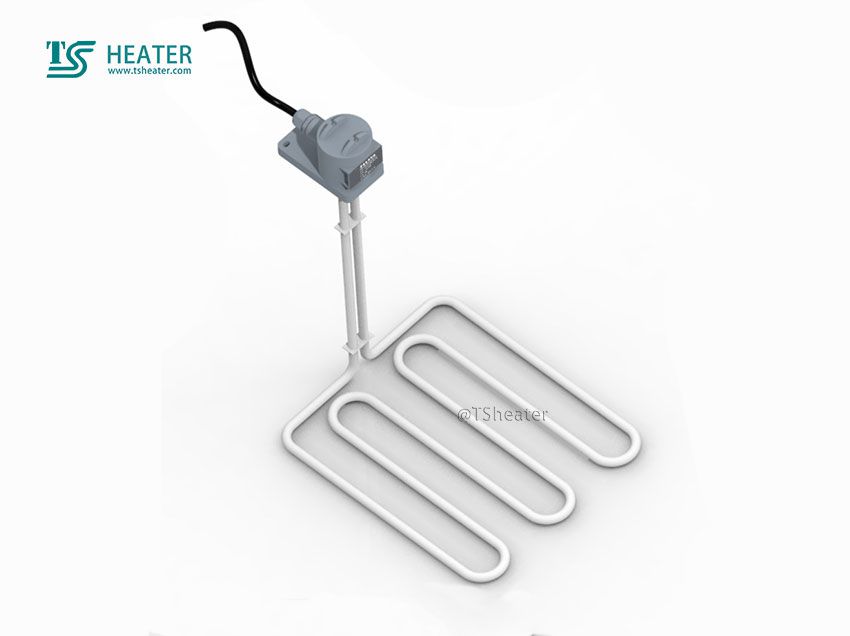

Anti-corrosion heating tube is a new type of electric heating tube which is resistant to strong corrosion. It is used for heating all kinds of corrosive liquids.

Ptfe Heaters

It has good aging resistance and good winding performance, and adopts low surface load design.

The connector is fully enclosed for acid and alkali protection, and the safety protection system for non-heating section and overheating is completely customized according to customers' requirements.

Good to ensure that the heater is not easy to burn out, long service life, full sealing, no corrosion, no leakage, with grounding protection, safe and reliable.

Applicable temperature below 110°C.

(heat in very thick liquid, must be configured with stirring)

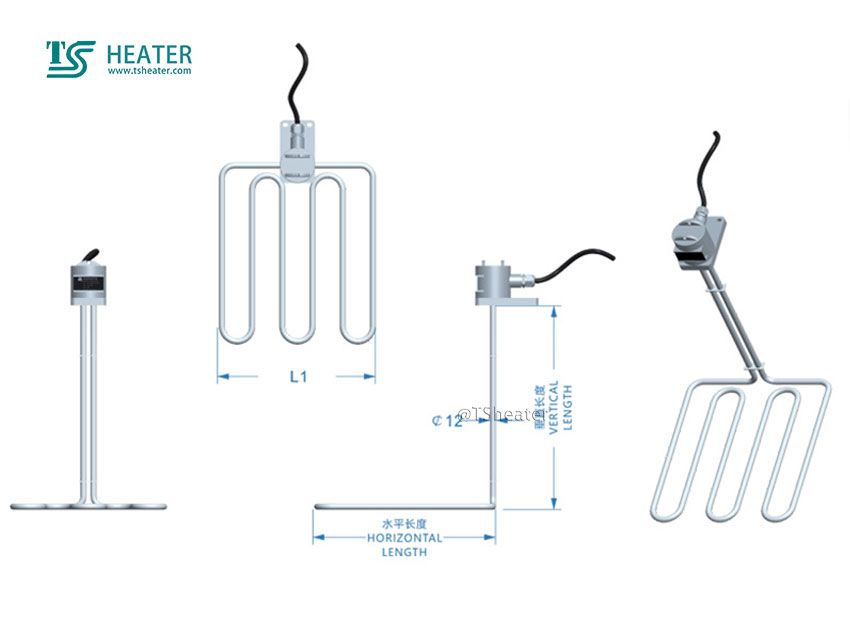

Mosquito-repellent incense type - anticorrosive teflon electric heating tube has the advantages of high thermal efficiency, energy saving, high cost performance, can design a variety of structural forms, such as spiral, L, U, W, mosquito-repellent incense type, combined type and so on.

It has been recognized by many listed companies and has been a long-term supplier of its mosquito-repellent incense teflon electric heaters.

We can undertake non-standard products, in voltage, power, specifications and product shape, as well as wiring mode, according to the customer's needs to let engineers design, welcome to map to sample custom production.

Ptfe Heaters

Anti-corrosion heating tube products:

1) the anti-corrosion heating tube is made of high quality stainless steel (sus316 or sus304) inner core of the electric heat tube, and is made of teflon tube (PTFE), which has strong corrosion resistance and is suitable for all kinds of corrosive liquid heating.

2) the heater is designed with low surface power (1.5w/c㎡) to ensure the service life of the product.

3) the installation location of the electric heater should pay attention to prevent the solid in solution from being deposited on the surface of the electric heater, or if the liquid is too thick and the liquid level is too low, it will burn out PTFE (iron fluoride) due to poor s

As a result of our own efforts and the help and support of our customers, our Copper Tube Condenser Fin Heat Exchanger Coil (Electronic coating) has gained a good reputation in the marketplace. We highlight the concept of 'professional creation of value and quality conquering the world'. While we are equipped with advanced equipment, we also pay attention to scientific management, starting from raw materials, and checking at each level to further improve product quality.