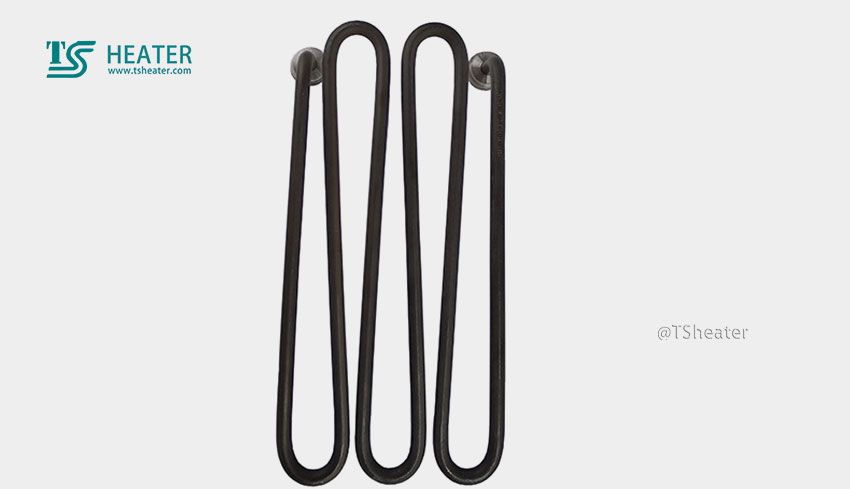

In the production process of electric range heating element, the surface of the pipe has been treated with a special process, which will help the problems in long-term use. At the same time, its structural design has its reliable sealing performance, which is convenient for installation and maintenance. The dimensions can be customized.

Welcome to consult:

Electric range heating element can produce various types and shapes of electric heating tubes according to the product drawings and technical requirements designed by users. The element materials can be made according to user requirements. And promise product quality and meet user needs.

Things to pay attention to when making electric range heating element

According to the usage environment:

Use in air:

1. Closed air heating

2. Circulating air heating

3. Special gas heating

Use in liquid:

Heating in water, heating in oil, heating in acid and alkali liquids (the heating area of the electric heating tube should be immersed and not exposed to the air). The watt density and materials used are different, and they should not be mixed up. A good use environment should not produce skin, Phenomenon such as thinning, dust, oil and water.

Acid and alkali, gas use:

1. Copper tube, SUS304#316 tube for general neutral environment,

2. Incoloy nickel alloy tube for weak acid and weak alkali environment,

3. Ti titanium alloy tube for moderate acid and alkali environment,

4. Strong acid and alkali environment, use quartz, Teflon Teflon tube, Incoloy nickel alloy tube,

5. SUS316 tube for 900℃ environment,

6. SUS304 tube for 700℃ environment,

7. Ti titanium alloy tube for 650℃ environment,

8. Cu copper tube for 300℃ environment,

9. Use Teflon Teflon tube below 110°C.