According to the customer's special requirements, the heating tube can be desalinated, so that the insulating heat conductor (magnesium oxide powder) inside the heating tube is completely crystallized and will not be carbonized for a long time, thereby prolonging the service life of the heating tube.

1. Features and applications of flange heating element

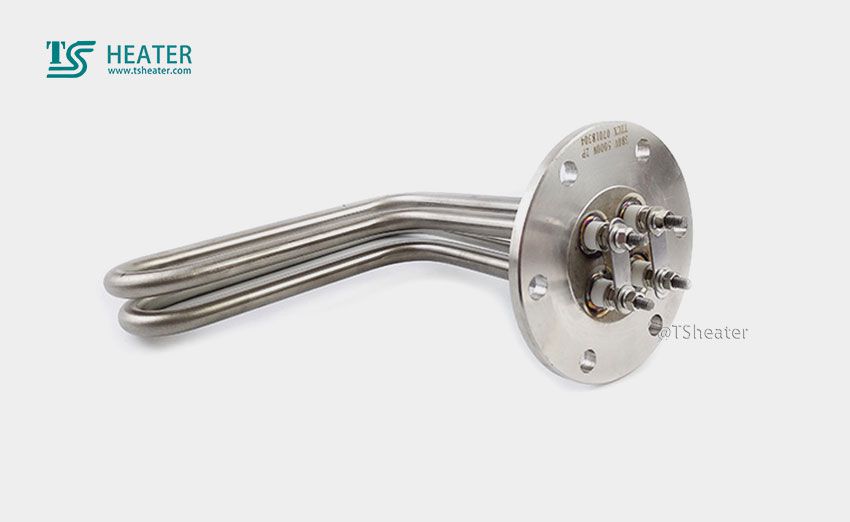

1) Flange heating element flange heating tube is centralized heating by multiple heating tubes welded on the flange. The key is to use the open and closed aqueous solution tank and the circulation heating.

2) Advantages: The surface output power is large so that the gas heats the surface load 2 to 4 times, the aspect ratio is a file, and the structure is compact. Because the overall is short and clustered, the reliability is good, and the installation does not require a support frame.

Most of the integral flange heating element uses an argon arc welding machine to connect the heating tube to the looper flange, and it can also use the method of tightening equipment, that is, each heating tube is welded with standard parts. Then use a nut to clamp with the flange cover. The pipeline is connected to the standard parts by an argon arc welding machine, with zero leakage. The scientific research processing technology is selected for the sealing of standard parts. The single root is easy to replace and replace, which greatly saves the maintenance cost afterward

Choose imported and cost-effective raw materials from China. The scientific production process and strict quality control ensure the excellent electrical equipment characteristics of the heating tube.

2. Brief description and principle of flange heating element

Flange heating element: U-shaped tubular electric heating material is selected. According to the design standard of different materials for heating, it is installed on the flange cover according to the output power configuration regulations, and inserted into the raw materials to be heated. The hot components need to be transmitted when working A lot of the heat generated is transferred to the heated material to increase the temperature of the material to meet the required processing technology regulations. When the material temperature reaches the preset value specified by the processing technology, the automatic control system adjusts the power of the electric heating device after PID calculation according to the temperature sensor data signal and completes the temperature control of the resistive load of the hot components. Make the temperature of the material even, and meet the required regulations; when the hot components are overheated or the low-level meter, the interlocking protection equipment of the hot components will immediately disconnect the heating switch power to prevent the hot components from burning and increase the service life.

3. the scope of application of flange heating element

Flange heating element is the key to heat insulation and heating of raw materials in various storage tanks, utensils, and automobile fuel tanks in crude oil, chemical plants, food, machinery, and equipment. The interface method can choose the wafer check valve or external thread internal hole sealing

flange heating element. This product can be customized according to customer regulations, showing engineering drawings, working voltage, output power, and specifications.