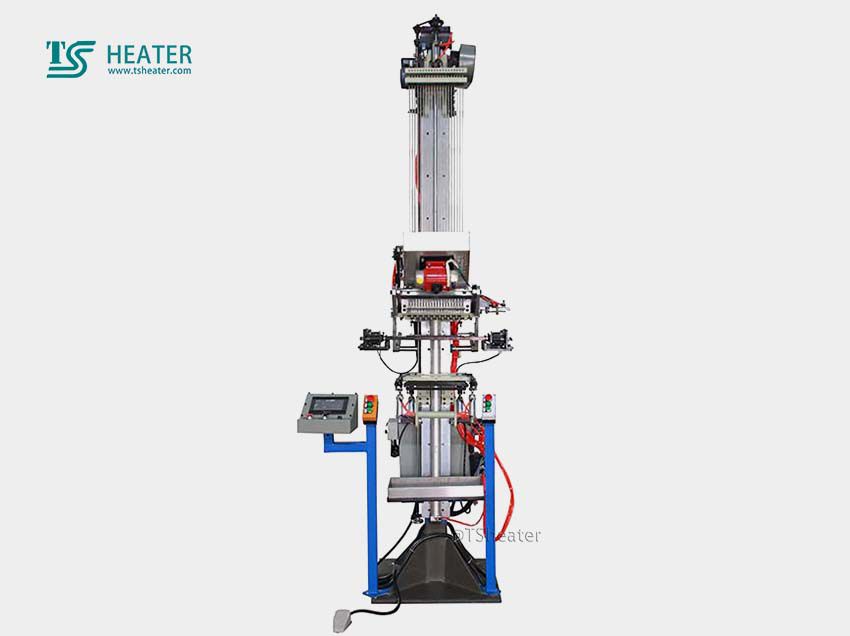

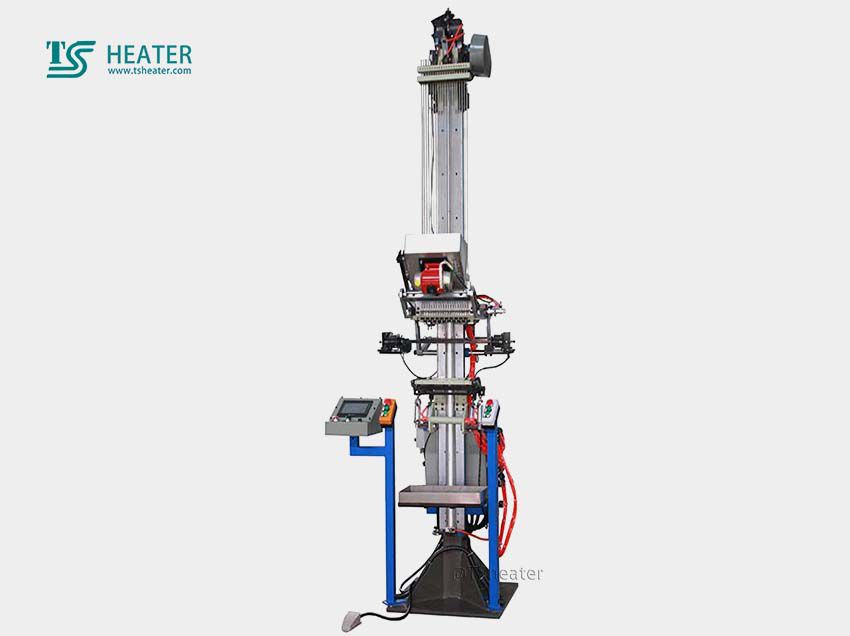

The heating element filling machine is an automatic filling machine. At the same time it is also a one-way machine, that is, a single-layer catheter. The main advantages of the machine: 1) Large capacity 2) Accelerate the filling speed, about 2.15g/cm3. 3) Simple operation 4) Using PLC touch screen control, the filling length will be more correct. Solve machine problems 5) A geared motor is used to drive the ascent of the duct mechanism, which is more stable than the gas-liquid steering mechanism.

Product: Heating element filling machine

Number: Heating element filling machine TLD-24

Parameters of heating element filling machine:

Gas station: 24 PCS

Maximum diameter of fueling pipe: 12.7mm

Filling length: 150mm--1000mm

Voltage and power: 380W 220V 600W

Air source: 0.6MPa clean compressed air

Filling speed: 6000-8000 PCS can be achieved in 8 hours.

Pipe size: a short pipe with a large diameter.

Heating element filling machine:

The heating element filling machine is an automatic filling machine. At the same time it is also a one-way machine, that is, a single-layer catheter.

A mandrel is installed inside the pipeline to position the heating wire module.

A linear cutting and binding head weld are installed on the top of the pipe; it is connected to the hole in the pipe. Magnesium powder flows downward from the tail of the duct.

The main advantages of the machine:

1) Large capacity

2) Accelerate the filling speed, about 2.15g/cm3.

3) Simple operation

4) Using PLC touch screen control, the filling length will be more correct.

Solve machine problems

5) A geared motor is used to drive the ascent of the duct mechanism, which is more stable than the gas-liquid steering mechanism.