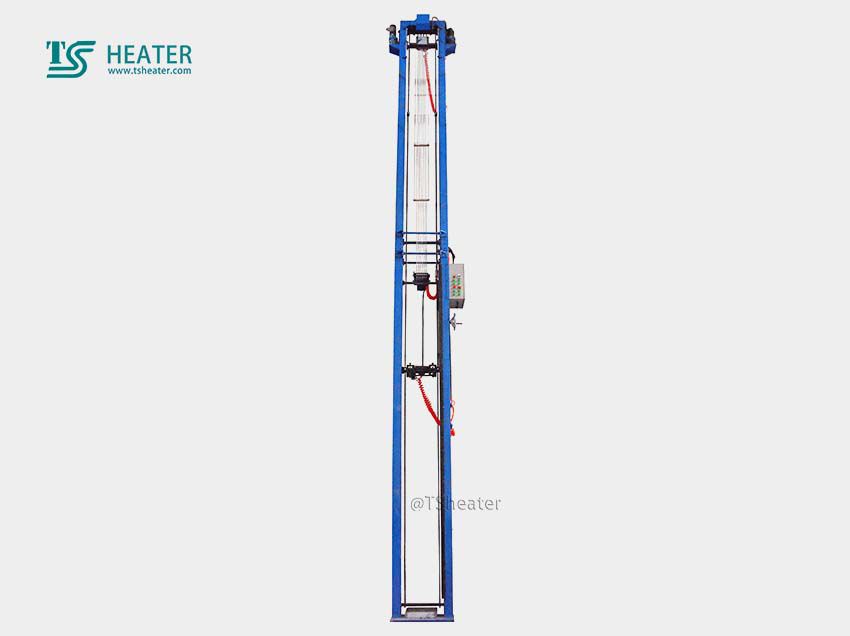

The heating tube filling machines introduce PLC and programmed counting components. The user can design the actual length (empty tube length) by operating on the touch screen, and it is very easy to adjust the length of the heating tube required. This method is more convenient and accurate, and the filling direction is more precise. Compared with the previous manual adjuster, the spiral nozzle inside the catheter and the exposed mandrel (hook) give it greater convenience.

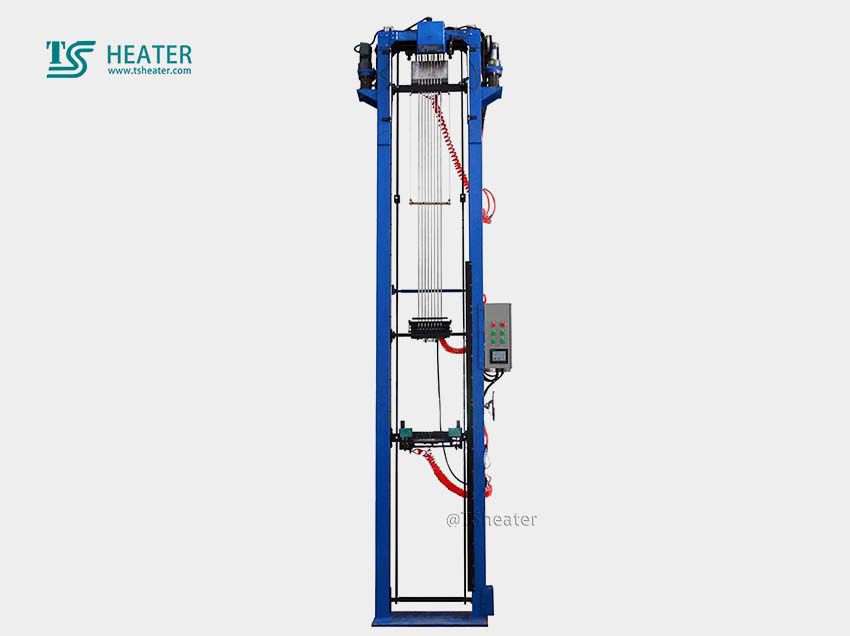

Product: Heating tube filling machines

Number: FM---heating tube filling machines

technical parameter:

The machine is divided into two types: 24 stations and 48 stations,

Diameter: 12.7 mm

The heating tube filling machines have been upgraded in many ways. Performance has improved a lot.

1) PLC,

2) Man-machine interface (touch screen),

3) Linear guide

4) Rotating fixture assembly.

The heating tube filling machines introduce PLC and programmed counting components. The user can design the actual length (empty tube length) by operating on the touch screen, and it is very easy to adjust the length of the heating tube required. This method is more convenient and accurate, and the filling direction is more precise. Compared with the previous manual adjuster, the spiral nozzle inside the catheter and the exposed mandrel (hook) give it greater convenience.

We designed pneumatic clamps and shorter parts (less than 1500mm) to quickly clamp 24 parts in one clamping process, thereby increasing productivity.

Improvement of heating tube filling machines:

Recently, we have improved the heating tube filling machines, replaced the traditional spiral nozzle with a three-layer tube structure, and improved the nozzle structure. The flow rate of MGO has become larger and the filling efficiency is higher. The spiral nozzle of our company is still the three-layer tube structure or the world's advanced equipment. The heating tube filling machine series has the world's most advanced filling equipment.