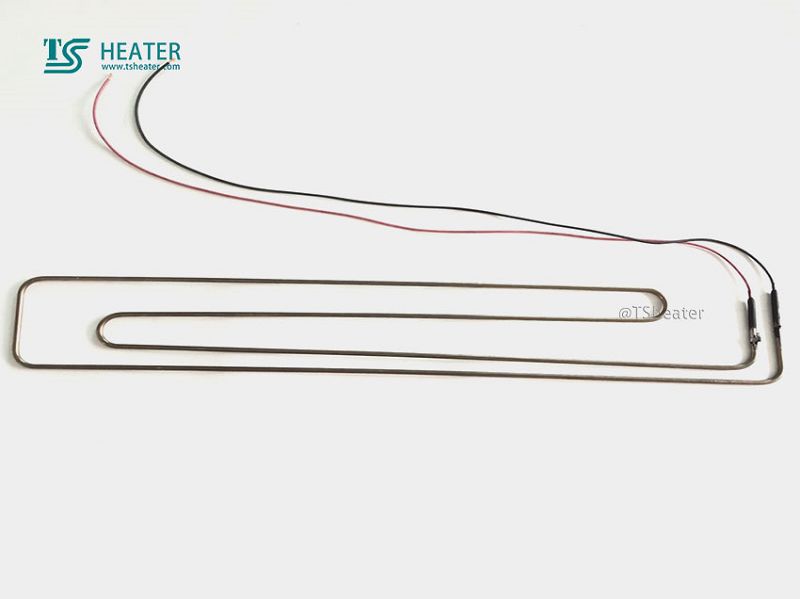

U Type Defrost Heating Tube Performance and application of melting (melting) frost electric heat pipe: melting (melting) frost electric heat pipe is an electrical element designed and developed for electric heating frost on various refrigeration equipment such as cold storage U Type Defrost Heating Tube

Sticking for the perception of 'Creating products of top quality and producing friends with people today from all around the world', we constantly place the desire of shoppers to start with for coil winder, alumina ceramic rod, finned heating element. Our long-term cooperation with foreign multinational companies has enabled us to have a perfect quality assurance system, and the performance indicators have been stable for a long time. We are highly honored to cooperate &develop with international partners by the scientific management, excellent quality, novel design, reasonable price and perfect service. Advanced technology and modernized management is our goal , which allows us in the forefront of the industry. Sincerely looking forward to develop with you together! We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success! By continuous innovation, we will present you with more valuable items and services, and also make a contribution for the development of the automobile industry at home and abroad.

Product introduction: U Type Defrost Heating Tube

Performance and application of melting (melting) frost electric heat pipe: melting (melting) frost electric heat pipe is an electrical element designed and developed for electric heating frost on various refrigeration equipment such as cold storage, refrigeration, display and island cabinet.Due to freezing equipment work, high indoor humidity, low temperature, cold and hot shock often wait for a characteristic, on the basis of the tubular electric heating element, is made of high quality modified magnesium oxide for packing, stainless steel shell, after shrinkage tube, two terminal made of special rubber seal, can make the electric heating tube in refrigeration equipment in normal use.And can bend any shape according to user's need.It can be conveniently mounted on the ribs of the cooling fan, the condenser and the chassis of the water-collecting disc for defrosting.

Technical data: U Type Defrost Heating Tube

State or 200 m Ω insulation resistance.

Insulation resistance acuity 30 M Ω after damp heat test.

Tidal leakage current ≤ 0.1ma.

Surface load ≤ 3.5w /cm?cars only

The operating temperature is 150℃.(Max. 300℃)

Product advantages: U Type Defrost Heating Tube

1. The products are mainly used in air coolers, refrigerators, freezers and other refrigeration equipment.

2. Good insulation and water resistance.

3. The production of frost heating tube generally USES 304 stainless steel as the outer tube material, has a good corrosive!

4. Generally, the oven is used to drain moisture, and the color is beige. High temperature annealing can be carried out, and the surface color of the electric heat pipe is black or dark green.

Type | MM | Inch | Voltage | Power | ΦD1mm | ΦD2mm |

U305 | 305 | 12'' | 110V/220V | 250W | 6.5mm | 9.5mm |

U355 | 355 | 14'' | 110V/220V | 280W | 6.5mm | 9.5mm |

U406 | 406 | 16'' | 110V/220V | 300W | 6.5mm | 9.5mm |

U457 | 457 | 18'' | 110V/220V | 335W | 6.5mm | 9.5mm |

U508 | 508 | 20'' | 110V/220V | 375W | 6.5mm | 9.5mm |

U533 | 533 | 21'' | 110V/220V | 395W | 6.5mm | 9.5mm |

U558 | 558 | 22'' | 110V/220V | 415W | 6.5mm | 9.5mm |

U584 | 584 | 23'' | 110V/220V | 455W | 6.5mm | 9.5mm |

U610 | 610 | 24'' | 110V/220V | 475W | 6.5mm | 9.5mm |

Factory Show

Certificate:

Payment & Delivery:

Our vision is to provide customers with value-added Hot Gas Defrosting Aluminum Type Block Ice Machine, create maximum value for shareholders and society, and achieve common development with relevant stakeholders. We plan to form an enterprise with strong market development capabilities, scientific research and development capabilities, project operation and maintenance capabilities. We have introduced advanced modern corporate management mechanisms, continuously strengthened the overall quality of corporate employees, established and improved related quality systems and other regulations, thereby enhancing the company's market competitiveness.